Process for preparing Ba TiO2 base laminated sheet type PTC thermosensitive resistor

A thermistor and preparation technology, applied in the direction of resistors with positive temperature coefficients, etc., can solve the problems of low mechanical strength of PTC ceramic sheets, it is difficult to ensure the contact between electrodes and ceramic sheets, etc., and the method is flexible and simple, The effect of high consistency, improved performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] (1) Ingredients and pre-burning

[0030] The composition of the PTC sample material is: (Ba 0.8 Sr 0.2 ) Ti 1.01 o 3 +1.5mol% SiO 2 +0.5mol%Al 2 o 3 +0.3mol%Y 2 o 3 +0.1mol%Mn(NO 3 ) 2 . After batching according to the above proportions, mix by ball milling, and pre-calcine at 1155°C for 2 hours.

[0031] (2) rolling film forming

[0032] The pre-burned PTC powder is ball milled and passed through a 60-mesh sieve. Take 50g of powder, add 17g of mass percent concentration of 18% polyvinyl alcohol (PVA) aqueous solution as adhesive, and add 6ml of glycerin as plasticizer, knead to form a plastic mass, and place it between the two rolls of the rolling machine. Repeated rolling in between, until it reaches a certain uniformity, density, smoothness and flexibility, then take it off, the thickness of the film is 0.3mm, and punch it into 55×40mm.

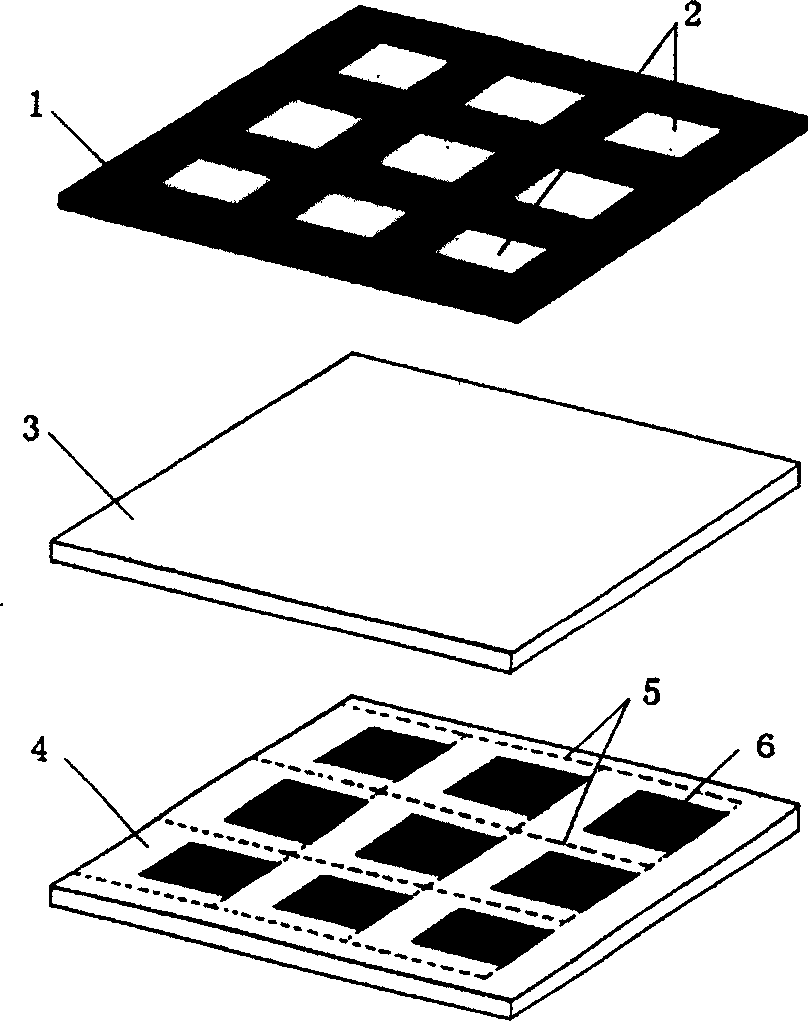

[0033] (3) Sputtering inner electrode

[0034] Cover the mask plate (the thickness is 1mm, and the plane size of ea...

example 2

[0041] The same method as in Example 1 was used to make the PTC green body, sputter the nickel electrode in the sputtering station, slice it and laminate it, and make the terminal electrode after hot pressing and reoxidation treatment in the reducing atmosphere furnace. Corresponding parameter is as follows respectively: the mass percent concentration of the PVA aqueous solution that chooses in the rolling film forming is 15% (wherein added the glycerin that accounts for PVA aqueous solution 4wt%), and its amount of adding accounts for about 37wt% of powder, and the film thickness of preparation is 0.2mm; H 2 -N 2 H in the mixed gas 2 / N 2 = 4% at 1325°C and 10 -10 Firing at an oxygen partial pressure of Mpa for 1.5 hours, then lowering the temperature to 1000°C at a rate of 280°C / h, and oxidizing in air for 45 minutes, then turning off the power and naturally cooling to room temperature.

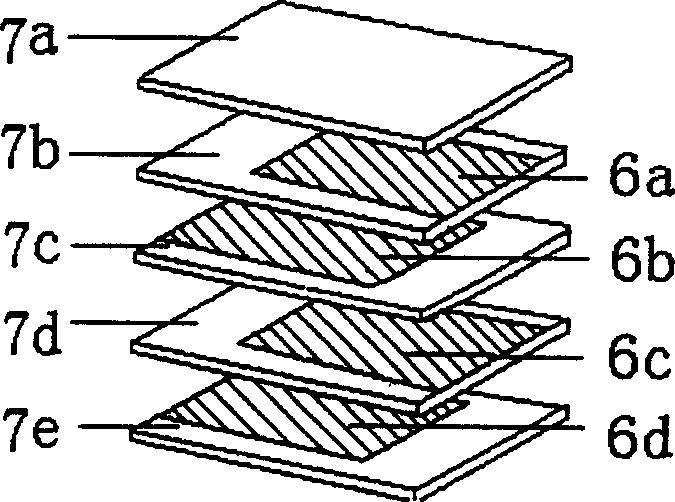

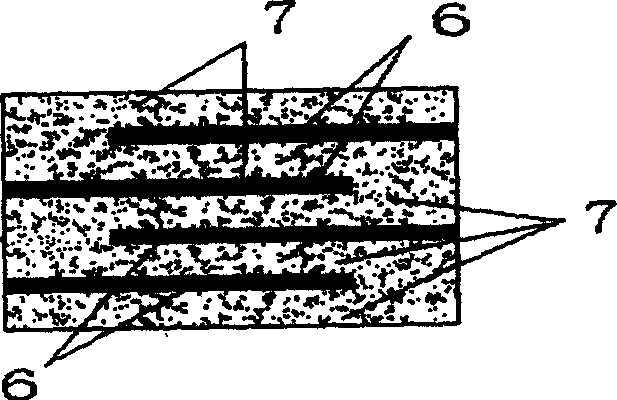

[0042] The layer number of the laminated PTC element is 5, the final size is 11×8×0...

example 3

[0044] The same method as in Example 1 was used to make the PTC green body, sputter the nickel electrode in the sputtering station, slice it and laminate it, and make the terminal electrode after hot pressing and reoxidation treatment in the reducing atmosphere furnace. Corresponding parameter is as follows respectively: the mass percent concentration of the PVA aqueous solution that chooses in the rolling film forming is 16% (wherein added the glycerin that accounts for PVA aqueous solution 5wt%), and its amount of adding accounts for 34wt% of powder material, and the film thickness of preparation is 0.4mm; H 2 -N 2 H in the mixed gas 2 / N 2 = 5% at 1320°C and 10 -11 Firing under the oxygen partial pressure of Mpa for 2 hours, then lowering the temperature to 900°C at a rate of 300°C / h, and oxidizing in air for 60 minutes, then turning off the power and naturally cooling to room temperature.

[0045] The layer number of the laminated PTC element is 9, the final size is 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Room temperature resistance | aaaaa | aaaaa |

| Temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com