Device and method for pretreating waste gas under moisture environment

A pretreatment, wet environment technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve problems such as exhaust fans increasing the manufacturing cost of exhaust gas treatment systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

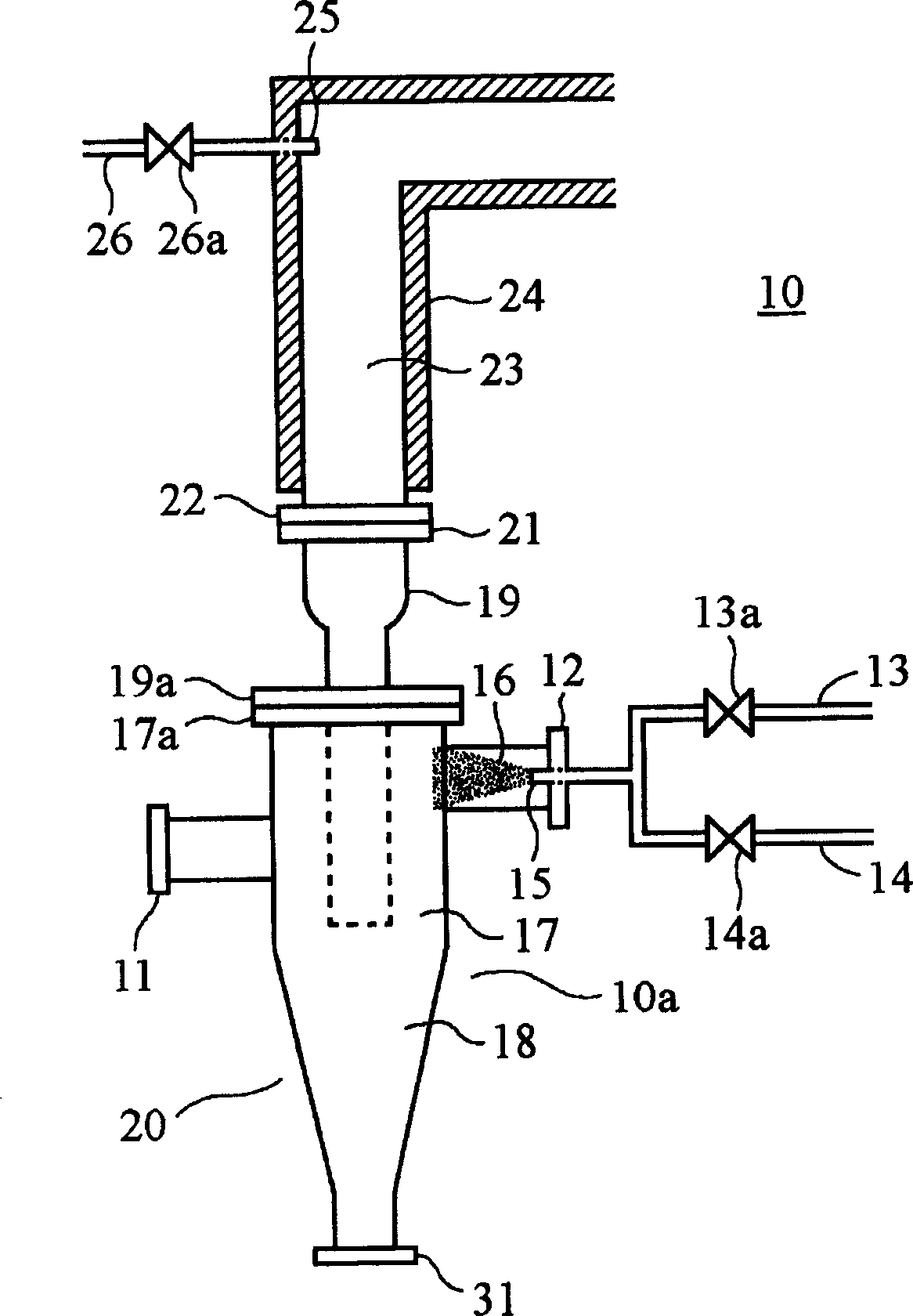

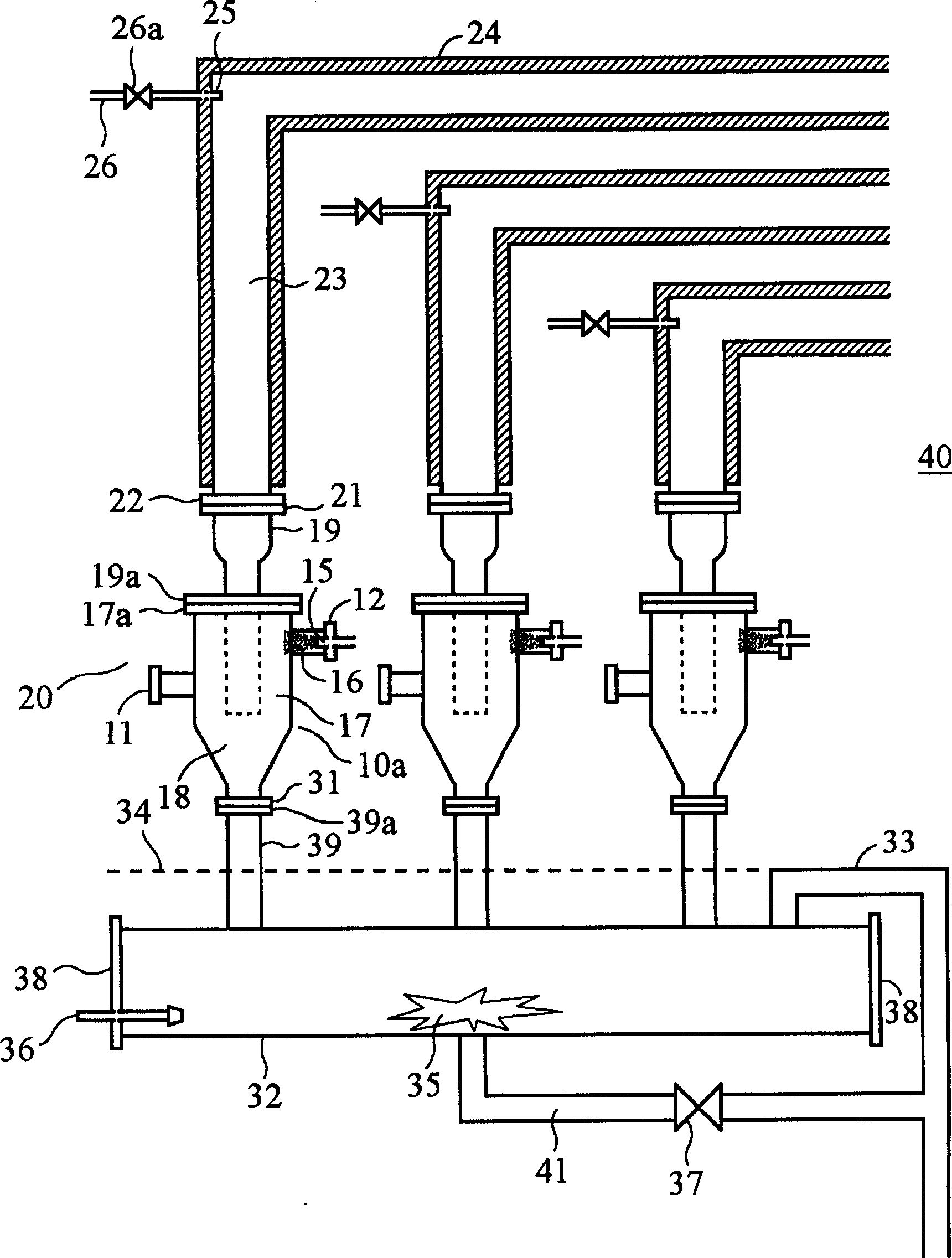

[0025] Referring to FIG. 1 , the wet pretreatment device 10 of the present invention includes a treatment section 20 and an atomizing nozzle 15 , and the treatment section 20 pretreats the exhaust gas by using the cyclone effect. The wet pretreatment device 10 that the present invention builds has waste gas inlet 11, reagent inlet 12, is used to discharge the waste gas outlet 21 of the waste gas through wet pretreatment, and the waste liquid outlet 31 that is used to discharge waste water, and described waste water comprises from described Fine powder and water-soluble components are removed from the exhaust gas.

[0026]The treatment section 20 of the wet pretreatment device 10 utilizes the cyclone effect, where the centrifugal force of a rotating fluid separates solid particles or liquid droplets dispersed in said fluid. By spraying the reagent into the exhaust gas stream in a rotating motion in the treatment section 20, water-soluble components and fines in the exhaust gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com