Method for producing yeast extracellular trehalose by two step fermentation method

A technology of trehalose and fermentation method is applied in the field of producing yeast extracellular trehalose, which can solve the problems of up to 1.5 to 1.8 dollars, and achieve the effects of improving food quality, reducing production cost and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

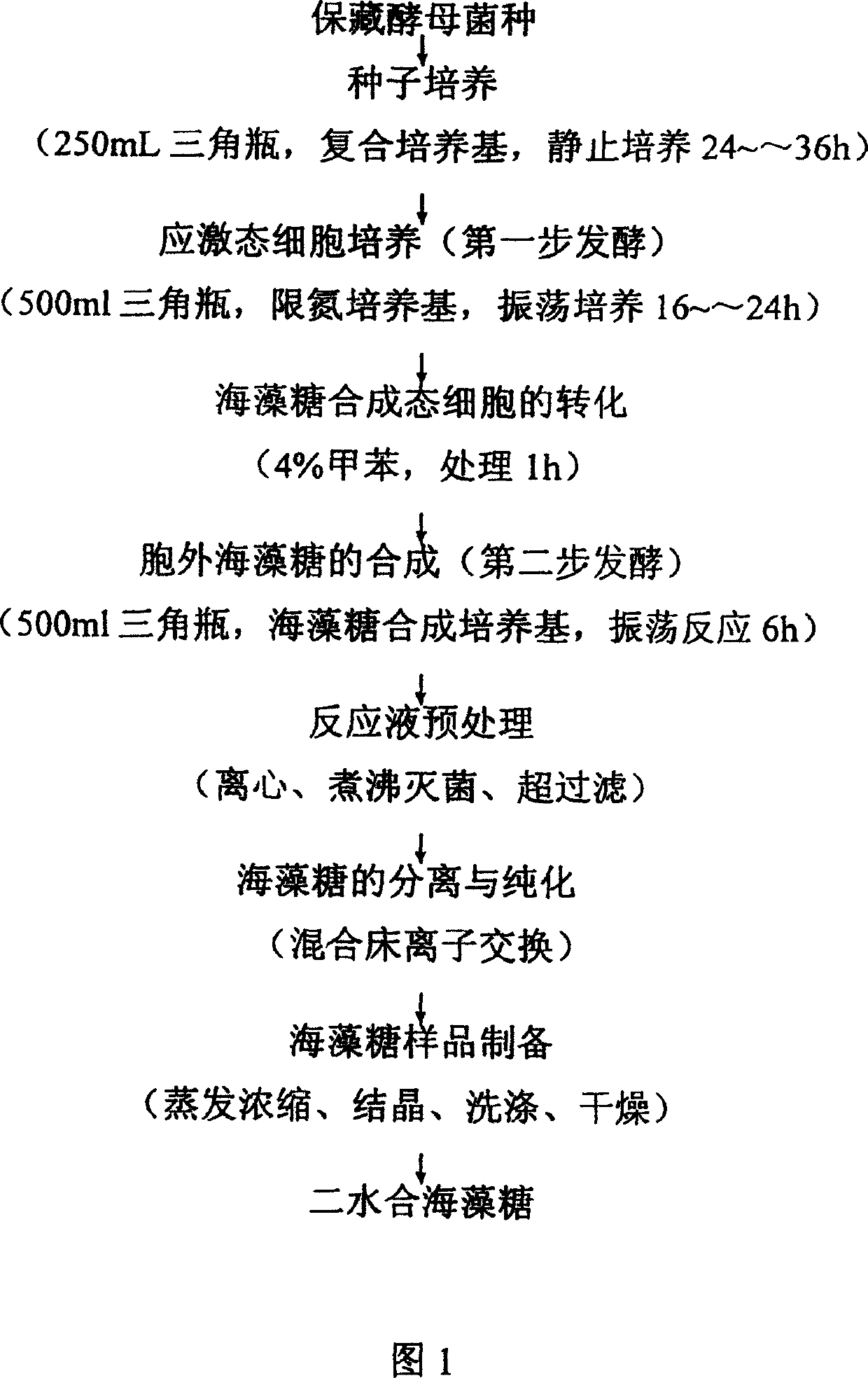

[0039] Example 1: Trehalose synthesis test in a 500mL Erlenmeyer flask, as shown in Figure 1:

[0040] 1. Stressed yeast cell culture: In a 250mL Erlenmeyer flask with 50mL of compound medium, inoculate 1-2 rings of the preserved strains on the slant, and culture at a constant temperature of 30°C for 24-36h, as the primary seed. Then put 100mL nitrogen-limited medium into a 500mL Erlenmeyer flask, add the first-grade seed solution with 5% inoculum, and culture at 30°C with shaking at 150r / min for 16-24h. In the later stage of cultivation, raise the temperature to 36-38°C to start the expression of yeast trehalose synthase gene, then add 2.5% NaCl to the medium to stimulate the formation of yeast trehalose synthase and increase the accumulation of trehalose in yeast . After culturing, centrifuge and wash twice with sterile water before use.

[0041] 2. Synthesis of trehalose: Weigh 2g of the yeast sludge in the stress state, add 10mL of 4% toluene, and shake at 36-38°C for 1 ...

Embodiment 2

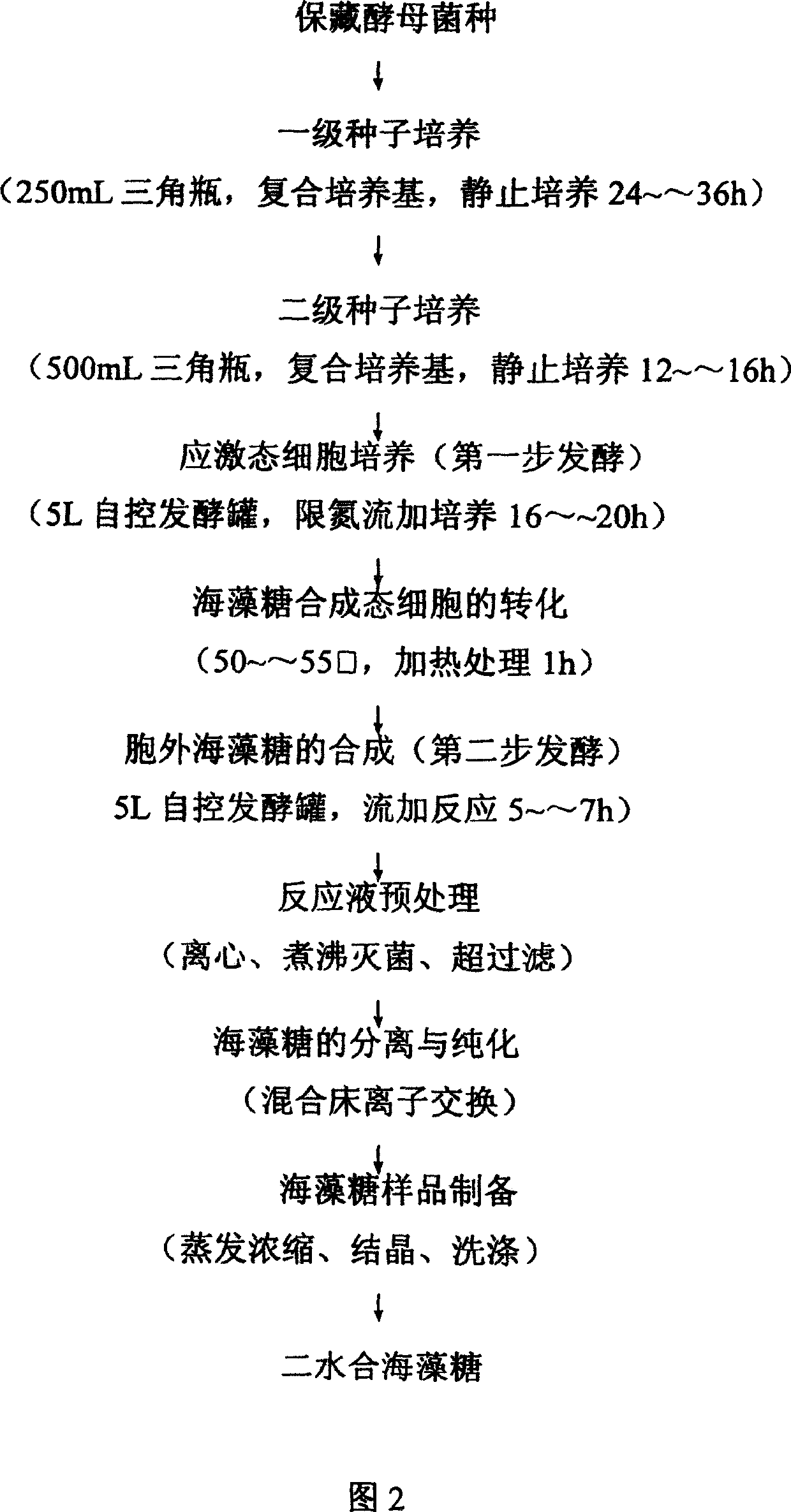

[0045] Example 2: Synthesis of trehalose in a 5L self-controlled fermenter as shown in Figure 2:

[0046] 1. Stressed yeast cell fed-batch culture: put the yeast slurry into a sterilized 5L self-controlled fermenter according to the inoculation amount of 2%, the culture temperature is 28 ° C ~ 30 ° C, and 10% Na 2 CO 3 Adjust the pH, add molasses and nutrient salts, so that the fermentable sugar in the medium is kept at 0.1-1% throughout the process, and the final liquid volume is about 3L; the pH is controlled at 3.8-4.5 at the beginning of the culture, and gradually increases after 10 hours After cultivating for a period of time, increase the pH of the fermentation broth to 5.0-7.0; add 2.5% NaCl in the later stage of cultivation, and increase the temperature of the fermentation broth to 36-38°C until the end of the cultivation. Yeast sludge was obtained by centrifugation, washed twice with sterile water, and preserved. At this time, yeast cells have accumulated more stres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com