Braze filler metal copper base alloy powder for diamond braze welding and its preparation method

A copper-based alloy, diamond technology, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of easy carbonization of diamond, affecting the quality of diamond tools, low brazing temperature, etc. Good self-sharpening and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The formula of the present embodiment is by weight percentage, and its composition is:

[0020] Sn 20% Ni 20% Cr 2.5% Si 0.5% B 3%

[0021] The balance is Cu.

[0022] The preparation method of the alloy powder of the present embodiment is: 1), take the batching by any one proportioning of claim 1-6,

[0023] 2) Under the protection of copper alloy smelting covering agent, melt the mixed ingredients in an intermediate frequency induction furnace at a temperature of 1000-1300°C. The copper alloy smelting covering agent is Hongguang brand produced by Shanghai Hongguang Metal Smelting Factory HGCJ-4 Copper Refining Covering Agent,

[0024] 3) Transfer the melted mixed ingredients to the tundish, use inert gas as the atomizing gas, and atomize the above-mentioned melted mixed ingredients at 900-1000°C through the atomizing nozzle, and form powder in the atomizing cylinder. The pressure of melting is 0.8mPa. The atomizing gas was nitrogen. The particle size of the prepa...

Embodiment 2

[0029] The formula of the present embodiment is by weight percentage, and its composition is:

[0030] Sn 20% Ni 15% Cr 2% Si 0.5% B 2%

[0031] The balance is Cu.

[0032] Preparation method is the same as embodiment 1

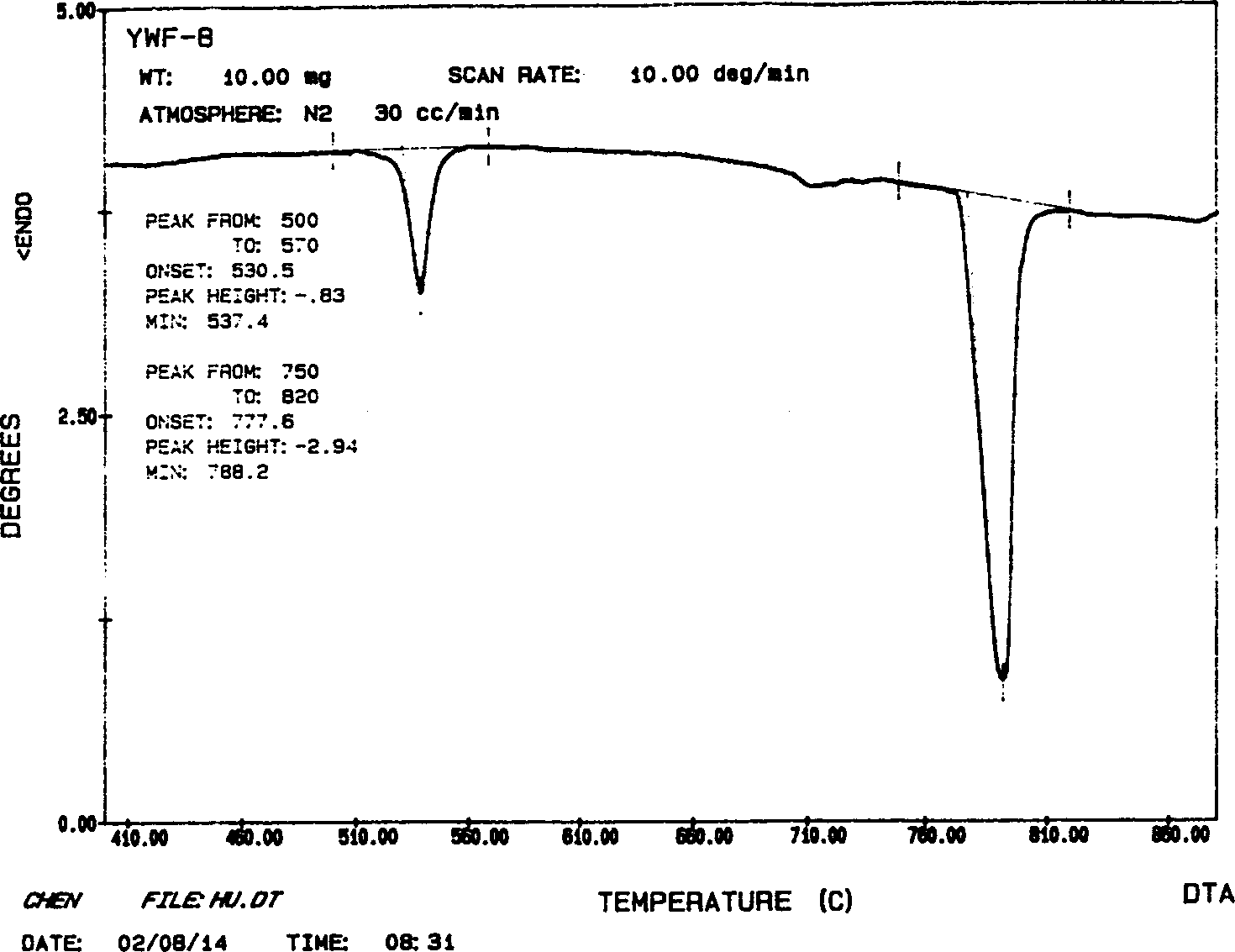

[0033] attached image 3 It is the melting point measurement curve of the alloy powder. The testing instrument is the DTA1700 high temperature differential calorimeter of the American PE company, and the measuring unit is the Analysis and Testing Center of Zhejiang University. The figure shows that the melting point of the alloy powder of this embodiment is between 760-810°C.

Embodiment 3

[0035] The formula of the present embodiment is by weight percentage, and its composition is:

[0036] Sn 23.5% Ni 10% Cr 2% Si 0.5%

[0037] B 1.5% The balance is Cu.

[0038] Preparation method is the same as embodiment 1

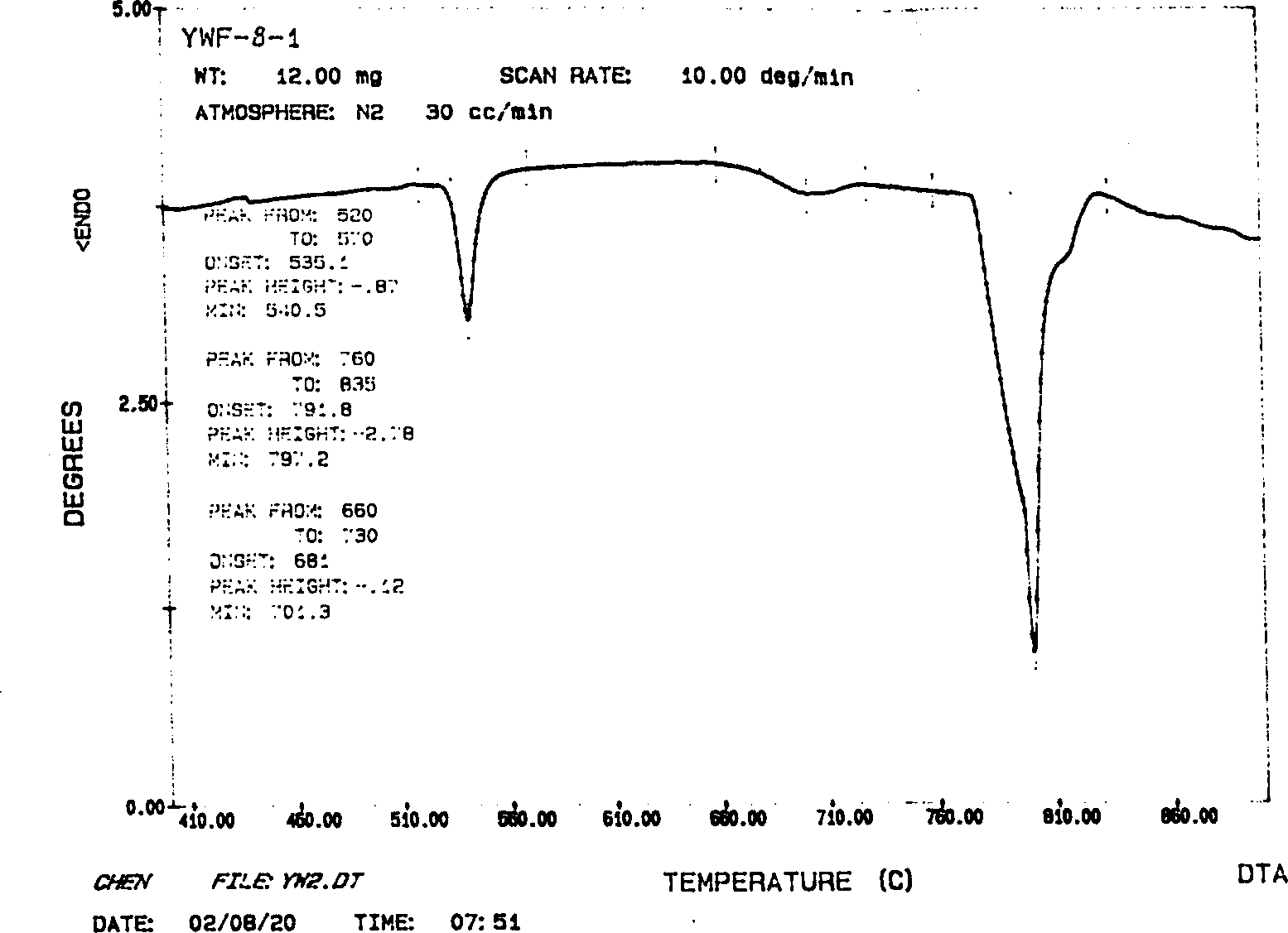

[0039] attached Figure 4 It is the melting point measurement curve of the alloy powder. The testing instrument is the DTA1700 high temperature differential calorimeter of the American PE company, and the measuring unit is the Analysis and Testing Center of Zhejiang University. The figure shows that the melting point of the alloy powder of this embodiment is between 760-810°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com