Dielectric material for thermostable laminated ceramic capacitor with basic-metal inner electrode

一种温度稳定型、多层陶瓷的技术,应用在固定电容器电介质、固定电容器、电容器等方向,能够解决不适合大规模生产、介电温度系数大、烧结温度高等问题,达到变化率小、介电损耗小、材料均匀性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

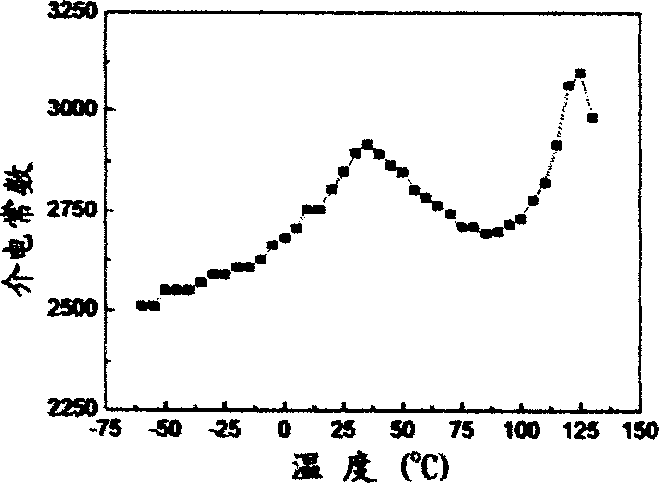

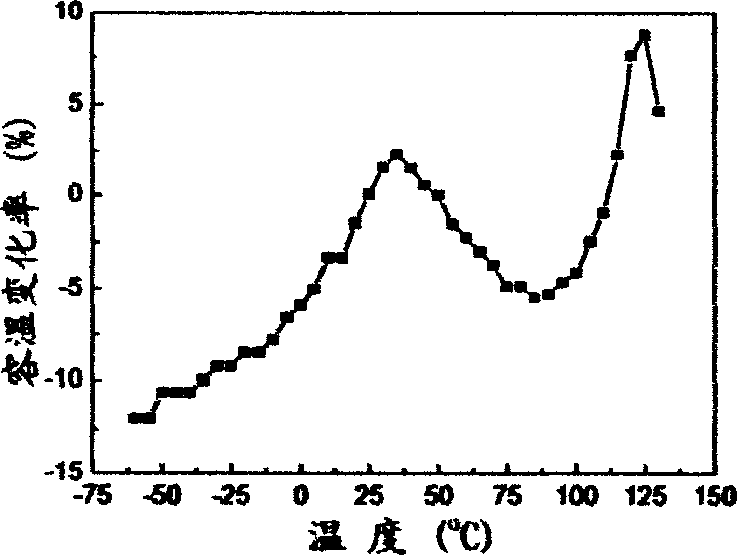

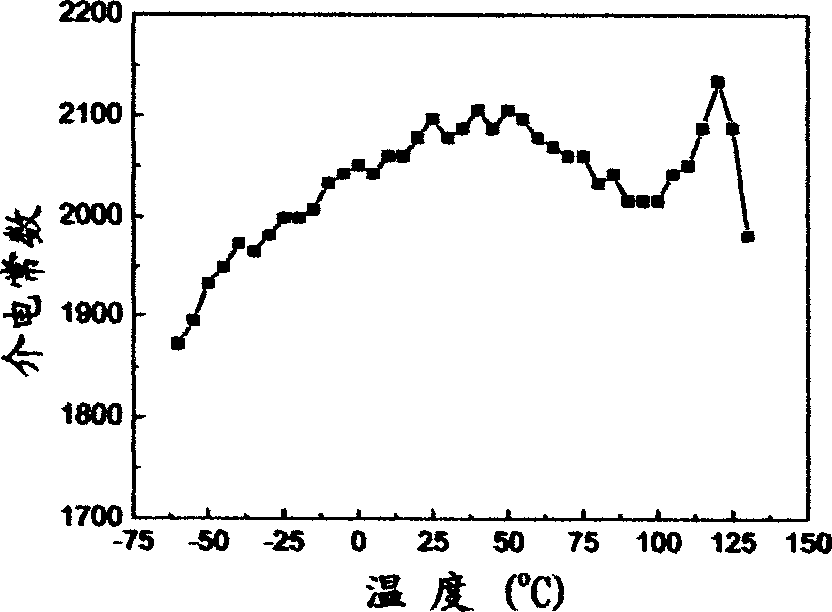

[0040] Embodiment 1, first according to BaTiO 3 : 96mol%; (grain size is 400nm) CaTiO 3 0.5mol%; CaO: 0.3mol%; SiO 2 0.8mol%; SrO: 0.3mol%; MnO 2 : 0.2mol%; MgO: 0.2mol%; Co 2 o 3 : 0.2mol%; Y 2 o 3 : 0.5mol%; Sm 2 o 3 : 1.0mol% proportioning and weighing. Then add glass frit (Ba A Ca (1-A) O) x ·(Si B Ti (1-B) o 2 ) (A=0.4, B=0.9, x=1.1), accounting for 2wt% of the above mixture. The above materials were mixed, ball milled and then dried. The ceramic material is cast into a diaphragm, superimposed with a Ni electrode to make a MLCC green body, and after debinding, it is sintered in a reducing atmosphere (N is introduced during the sintering process). 2 / H 2 , while humidifying, the oxygen partial pressure is controlled at 10 -10 atm, at a rate of 200°C / hour to 1250°C, the holding time is 2 hours), and then annealed under weak oxidation conditions (furnace temperature is 1100°C, holding time is 4 hours, and the oxygen partial pressure is controlled at 10 -...

Embodiment 2

[0042] Embodiment 2, first according to BaTiO 3 : 95.2mol%; (grain size is 200nm) CaTiO 3 : 0.7mol%; CaO: 0.4mol%; SiO 2 : 0.8mol%; SrO: 0.3mol%; MnO 2 : 0.3mol%; MgO: 0.3mol%; Co 2 o 3 : 0.2mol%; Y 2 o 3 : 0.8mol%; Lu 2 o 3 : 1.0mol% proportioning and weighing. Then add glass frit (Ba A Ca (1-A) O) x ·(Si B Ti (1-B) o 2 ) (A=0.5, B=0.8, x=1), accounting for 1.5wt% of the above mixture. The above materials were mixed, ball milled and then dried. The ceramic material is cast into a diaphragm, superimposed with a Ni electrode to make a MLCC green body, and after debinding, it is sintered in a reducing atmosphere (N is introduced during the sintering process). 2 / H 2 , while humidifying, the oxygen partial pressure is controlled at 10 -9 atm, the temperature was raised to 1200°C at a rate of 200°C / hour, and the holding time was 2 hours), and then annealed under weak oxidation conditions (furnace temperature was 1100°C, holding time was 4 hours, and the oxygen pa...

Embodiment 3

[0044] Embodiment 3, first according to BaTiO 3 : 95mol%; (grain size is 500nm) CaTiO 3 : 0.7mol%; CaO: 0.4mol%; SiO 2 : 0.7mol%; SrO: 0.3mol%; MnO 2 : 0.5mol%; MgO: 0.4mol%; Co 2 o 3 : 0.2mol%; Y 2 o 3 : 0.7mol%; Gd 2 o 3 : 1.1mol% proportioning and weighing. Then add glass frit (Ba A Ca (1-A) O) x ·(Si B Ti (1-B) o 2 ) (A=0.5, B=0.9, x=1.1), accounting for 2.5wt% of the above mixture. The above materials were mixed, ball milled and then dried. The ceramic material is cast into a diaphragm, superimposed with a Ni electrode to make a MLCC green body, and after debinding, it is sintered in a reducing atmosphere (N is introduced during the sintering process). 2 / H 2 , while humidifying, the oxygen partial pressure is controlled at 10 -9 atm, the temperature was raised to 1280°C at a rate of 200°C / hour, and the holding time was 2 hours), and then annealed under weak oxidation conditions (furnace temperature was 1100°C, holding time was 4 hours, and the oxygen pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com