Method for preparing biodegradable water treatment agent PECS

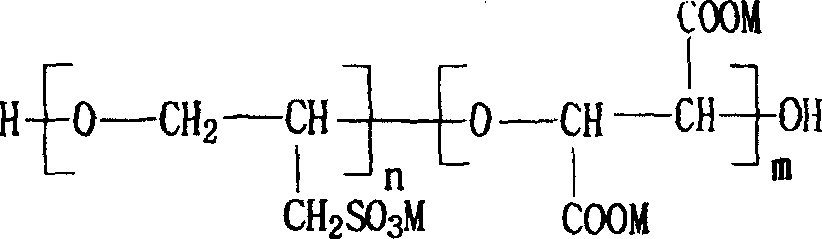

A technology of polyepoxy sulfocarboxylate and water treatment agent, which is applied in the field of water treatment, can solve the problem that the corrosion and scale inhibition performance cannot reach the use effect of multi-component copolymer, and limit the popularization and application of environment-friendly scale inhibitor and dispersant. Simple and other problems, to achieve the effect of good scale inhibition and dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 7 g of isopropanol to 98 g of sodium bisulfite aqueous solution (concentration: 40%) under stirring, and add 25 g of epichlorohydrin dropwise at 85° C., and the reaction time is 2 hours. Cool down to 40°C, add 42g of 40% sodium hydroxide under cooling and stirring, remove 15g of liquid by distillation under reduced pressure, then add 135g of sodium epoxysuccinate aqueous solution (concentration is 25%) and 1g of barium chloride to control the pH The value was 14, and reacted at 70° C. for 5 hours to obtain a yellow-brown viscous solution of sodium polyepoxysulfonate with a solid content of not less than 30%.

Embodiment 2

[0024] 20 g of isopropanol was added to 84 g of sodium bisulfite aqueous solution (concentration: 40%) under stirring, and 25 g of epichlorohydrin was added dropwise at 65° C., and the reaction time was 3 hours. Cool down to 40°C, add 42g of 40% sodium hydroxide under cooling and stirring, remove 15g of liquid by distillation under reduced pressure, then add 135g of sodium epoxysuccinate aqueous solution (concentration is 25%) and 1g of barium chloride to control the pH The value was 12, and reacted at 80° C. for 4 hours to obtain a yellow-brown viscous solution of sodium polyepoxysulfonate with a solid content of not less than 30%.

Embodiment 3

[0026] 15 g of isopropanol was added to 80 g of sodium bisulfite aqueous solution (concentration: 40%) under stirring, and 25 g of epichlorohydrin was added dropwise at 85° C., and the reaction time was 2 hours. Cool down to 40°C, add 42g of 40% sodium hydroxide under cooling and stirring conditions, remove 15g of liquid by distillation under reduced pressure, then add 135g of sodium epoxysuccinate aqueous solution (concentration is 25%) and 1g of strontium nitrate to control the pH value 10, and reacted at 90°C for 3 hours to obtain a yellow-brown viscous solution of sodium polyepoxysulfonate with a solid content of not less than 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com