Photoresist pattern thickness-increasing material, photoresist pattern containing it and its use

A technology of photoresist pattern and thick photoresist, which is applied in the direction of photosensitive material processing, application of radioactive source radiation, photosensitive material for optomechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

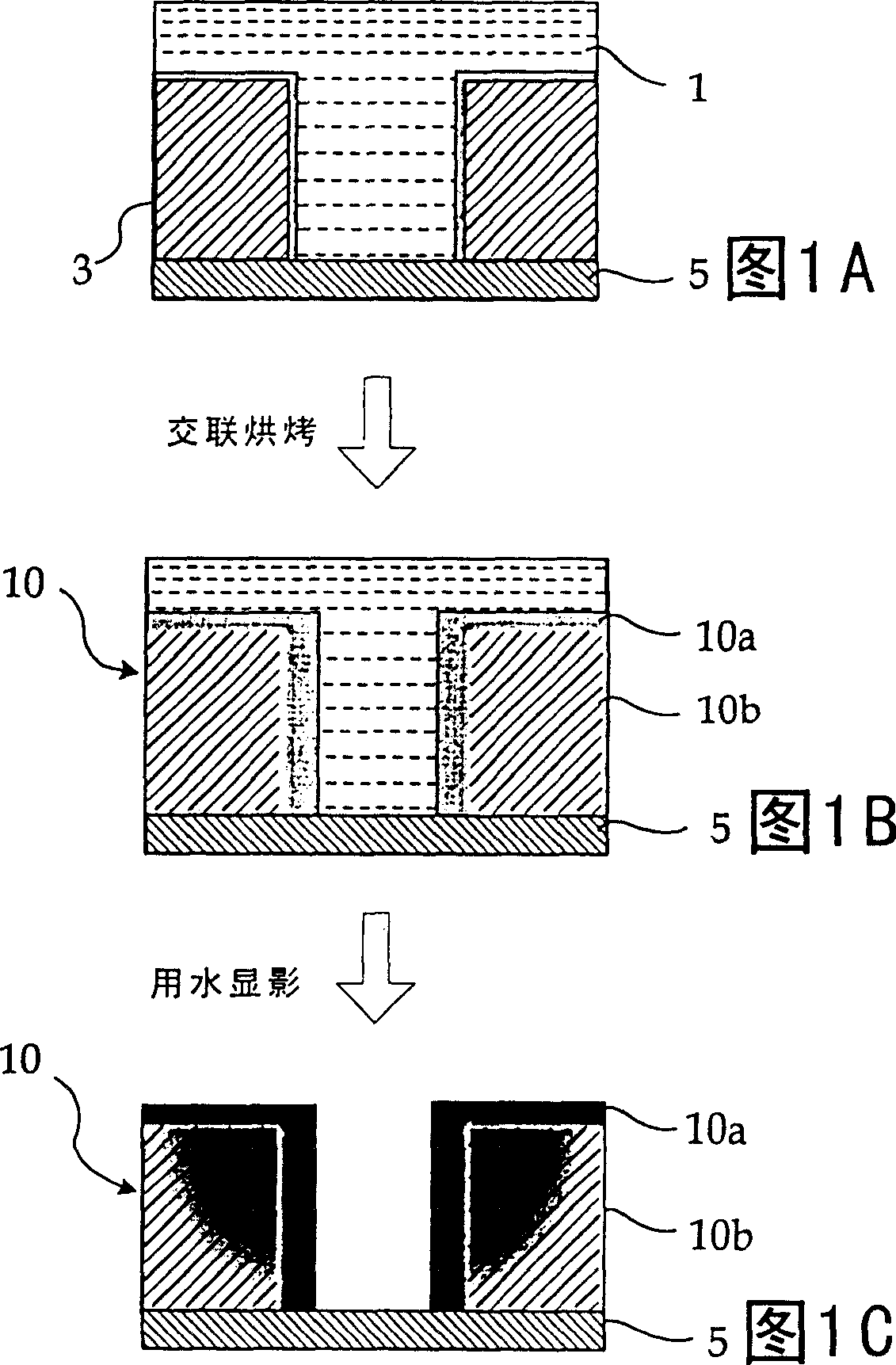

Method used

Image

Examples

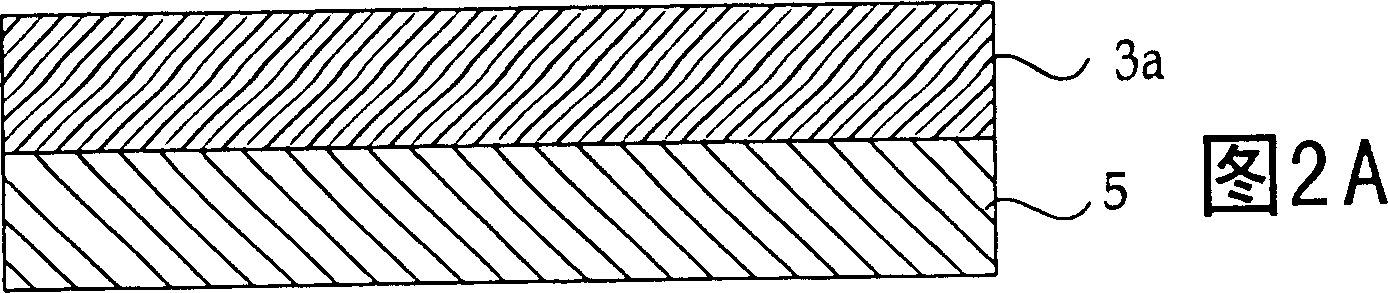

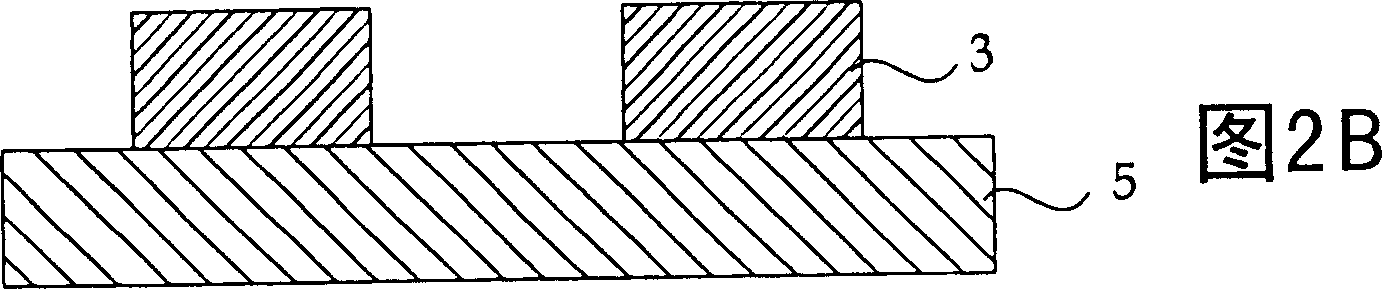

example 1

[0161] Preparation of photoresist pattern thickening material

[0162] The photoresist pattern thickening material A to the photoresist pattern thickening material F of the present invention were prepared, and their compositions are shown in Table 1. Note that in Table 1, the units of values in parentheses are mass fractions. In the "Resin" column, "KW-3" is a polyvinyl acetal resin (manufactured by Sekisui Chemical Co. Ltd.). In the "crosslinking agent" column, "biurea" is tetramethoxymethylglycol uril, and "urea" is N,N'-dimethoxymethyldimethoxy ethyl urea. In the "Surfactant" column, "TN-80" is a nonionic surfactant (polyoxyethylene monoalkyl ether surfactant manufactured by Asahi Denka Co. Ltd.). In addition, a mixed liquid of pure water (deionized water) and isopropanol (mass ratio of pure water (deionized water): isopropanol is 82.6:0.4) is used as a resin, crosslinking agent and nitrogen-containing compound other main solvent components.

[0163]

[016...

example 2

[0176] As shown in FIG. 3A , an interlayer insulating film 12 is formed on a silicon substrate 11 . As shown in FIG. 3B, a titanium film 13 is formed on the interlayer insulating film 12 by a sputtering method. Then, as shown in FIG. 3C, a photoresist pattern 14 is formed. The opening 15a is formed by patterning the titanium film 13 by reactive ion etching by using the photoresist pattern 14 as a mask. Next, as shown in FIG. 3D, the photoresist pattern 14 is removed by reactive ion etching, and an opening 15b is formed in the interlayer insulating film 12 by using the titanium film 13 as a mask.

[0177] Then, the titanium film 13 is removed by a wet process, and as shown in FIG. 4E, a TiN film 16 is formed on the interlayer insulating film 12 by a sputtering method. Next, a Cu thin film 17 is grown on the TiN film 16 by electrolytic plating. Then, as shown in FIG. 4F, planarization (leveling) is carried out by CMP, so that the isolation metal and the Cu thin film (the firs...

example 3

[0182] Flash memory and process for manufacturing same

[0183] Example 3 is an example of a semiconductor device applying the photoresist pattern thickening material of the present invention and a process for manufacturing the semiconductor device. Note that in Example 3, the photoresist films 26, 27, 29, 32, and 34 to be described hereinafter are those that have been thickened by using the photoresist pattern thickening material of the present invention by the same process as in Example 1 and Example 2. thick photoresist films.

[0184] 6A and 6B are top views (top views) of a FLASH EPROM called a FLOTOX type or ETOX type. Note that FIGS. 7A to 7C , 8D to 8F , and 9G to 9I are schematic cross-sectional views for explaining an example of a process of manufacturing a FLASH EPROM. In FIGS. 7A to 9I , the diagram on the left is the memory cell portion (first element region), which is the direction of the gate width of the portion where the MOS transistor with the floating gate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com