Process for preparing boron nitride nano tube

A boron nitride nanotube and boron oxide technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of low yield and low purity of boron nitride nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

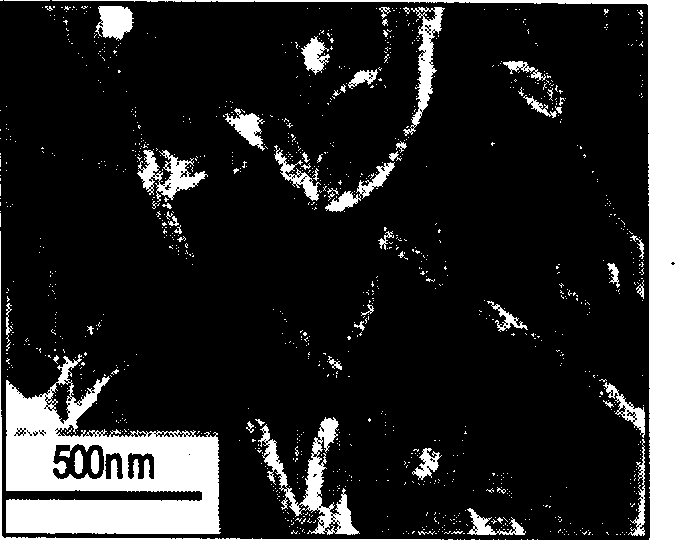

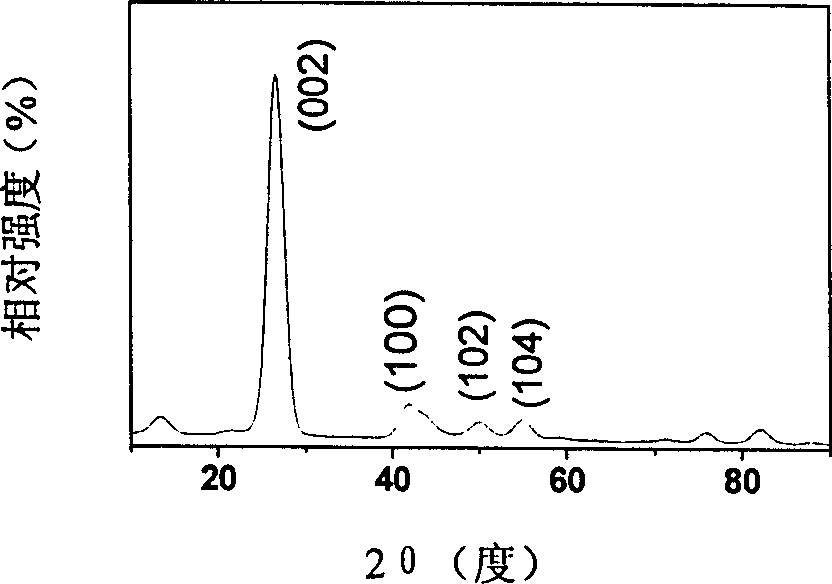

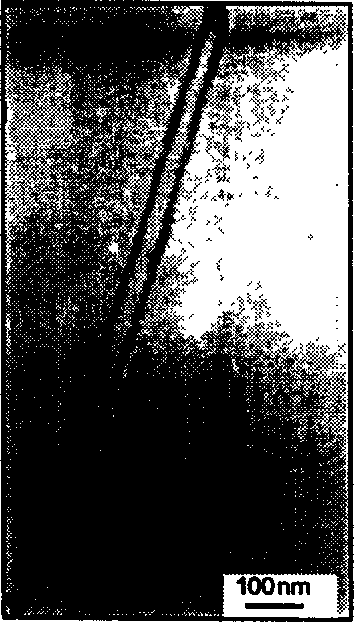

[0021] Embodiment 1: be the boron powder that purity is 99.8% as raw material, feed the ammonia gas of flow in the vacuum tube furnace after ball milling for a certain period of time and heat, the flow velocity of ammonia gas is 100ml / min, the speed of heating up 10C ° / min . When the temperature reaches 1000°C, keep at constant temperature for another 6 hours. Wash the sample several times with dilute hydrochloric acid, distilled water and ethanol, and dry it in a vacuum oven to obtain a white powder, which is the prepared boron nitride nanotubes with bamboo structure.

Embodiment 2

[0022] Embodiment 2: With the boron powder that purity is 99.8% as raw material, feed the ammonia gas of flow in vacuum tube furnace after ball milling for a certain period of time and heat, the flow rate of ammonia gas is 100ml / min, the speed of heating up 10C ° / min . When the temperature reaches 1200°C, keep at constant temperature for another 6 hours. A white powder is obtained, which is the prepared boron nitride nanotubes mainly having a cylindrical structure and a small amount of bamboo structure.

Embodiment 3

[0024] A certain proportion of boron powder (purity 99.8%) and Fe 2 o 3 (Analytical pure) After ball milling, feed flowing ammonia in the vacuum tube furnace for heating, the flow rate of ammonia is 100ml / min, and the speed of heating is 6-10C° / min. When the temperature reaches 1300°C, keep at constant temperature for another 3 hours. Wash the sample several times with dilute hydrochloric acid, distilled water and ethanol, and dry it in a vacuum oven to obtain a white powder, which is the prepared boron nitride nanotube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com