Cobalt oxide of lithium battery grade and its preparation method

A cobalt oxide and lithium battery technology, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of affecting the shape of lithium cobaltate, difficulty in uniform mixing, and high cost of cobalt oxide, so as to achieve easy industrial application and promotion, and anti-mixed wear of particles High-intensity, easy-to-apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

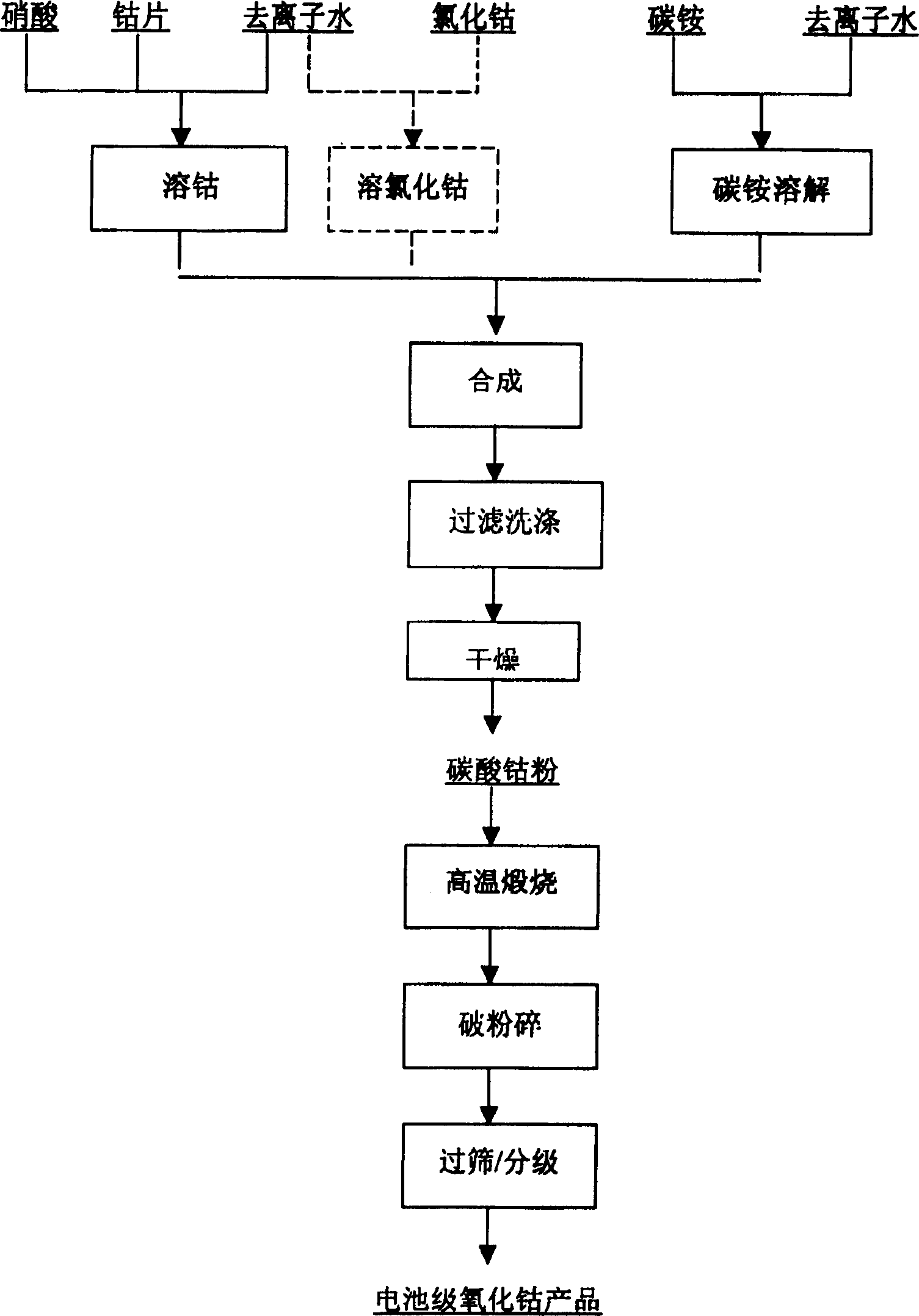

Method used

Image

Examples

Embodiment 1

[0045]Cobalt chloride is dissolved with deionized water, the cobalt content in the solution is 195g / L, and the impurity content is less than 100ppm; Dissolve food-grade ammonium bicarbonate with hot deionized water, the temperature is 30°C, and the solution concentration is 185g / L; Stir and heat the ammonium bicarbonate solution to 65°C, and add the cobalt nitrate solution into the reaction kettle filled with ammonium bicarbonate at a flow rate of 2L / min under stirring at 105rpm; the ammonium-cobalt dosage ratio is 2.8; continue stirring for 60 minutes after the addition ; Filter the cobalt carbonate precipitate and wash twice with 80°C deionized water; put the washed cobalt carbonate in a drying oven and dry at 150°C for 2 to 5 hours; transfer to a well-ventilated and oxygen-enriched muffle Calcined in the furnace at 500°C for 5 hours, then put it into a tunnel kiln, controlled the atmosphere of the kiln to be slightly oxygen-enriched, calcined at 800°C for 10 hours, and obtai...

Embodiment 2

[0048] Add high-purity electrolytic metal cobalt to chemically pure nitric acid solution to dissolve, the cobalt content in the solution is 220g / L, the free acid is 1.0g / L, and the impurity content is less than 100ppm; dissolve food-grade ammonium bicarbonate with hot deionized water, The temperature is 30°C, the solution concentration is 195g / L; the ammonium bicarbonate solution is stirred and heated to 40°C, and the cobalt nitrate solution is added to the reaction kettle filled with ammonium bicarbonate at a flow rate of 2L / min under stirring at 105rpm; The ammonium cobalt dosage ratio is 3; the stirring is continued for 60 minutes after the addition; the cobalt carbonate precipitate is filtered and washed twice with deionized water; The bowl enters the tunnel kiln, the atmosphere of the kiln is controlled to be in an oxygen-rich state, and it is calcined at 900°C for 3 hours. After crushing, sieving, and grading, battery-grade cobalt oxide powder is obtained. The technical ...

Embodiment 3

[0051] Add high-purity electrolytic metal cobalt to chemically pure nitric acid solution to dissolve, the cobalt content in the solution is 175g / L, the free acid is 1.0g / L, and the impurity content is less than 100ppm; dissolve food-grade ammonium bicarbonate with hot deionized water, The temperature is 30°C, the solution concentration is 185g / L; the ammonium bicarbonate solution is stirred and heated to 65°C, and the cobalt nitrate solution is added to the reaction kettle filled with ammonium bicarbonate at a flow rate of 2L / min under stirring at 105rpm; The ammonium-cobalt dosage ratio is 4.5; after the addition, continue to stir for 60 minutes; filter the precipitated cobalt carbonate and wash it twice with deionized water; put the washed cobalt carbonate in a drying oven and dry at 150°C for 2 to 5 hours; then pack The bowl enters the tunnel kiln, the atmosphere of the kiln is controlled to be in an oxygen-rich state, and it is calcined at 920°C for 3 hours. After crushing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com