Resistor

A technology of resistors and resistance alloys, applied in the direction of resistors, trimmer resistors, resistor parts, etc., can solve problems such as difficulty in roughening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

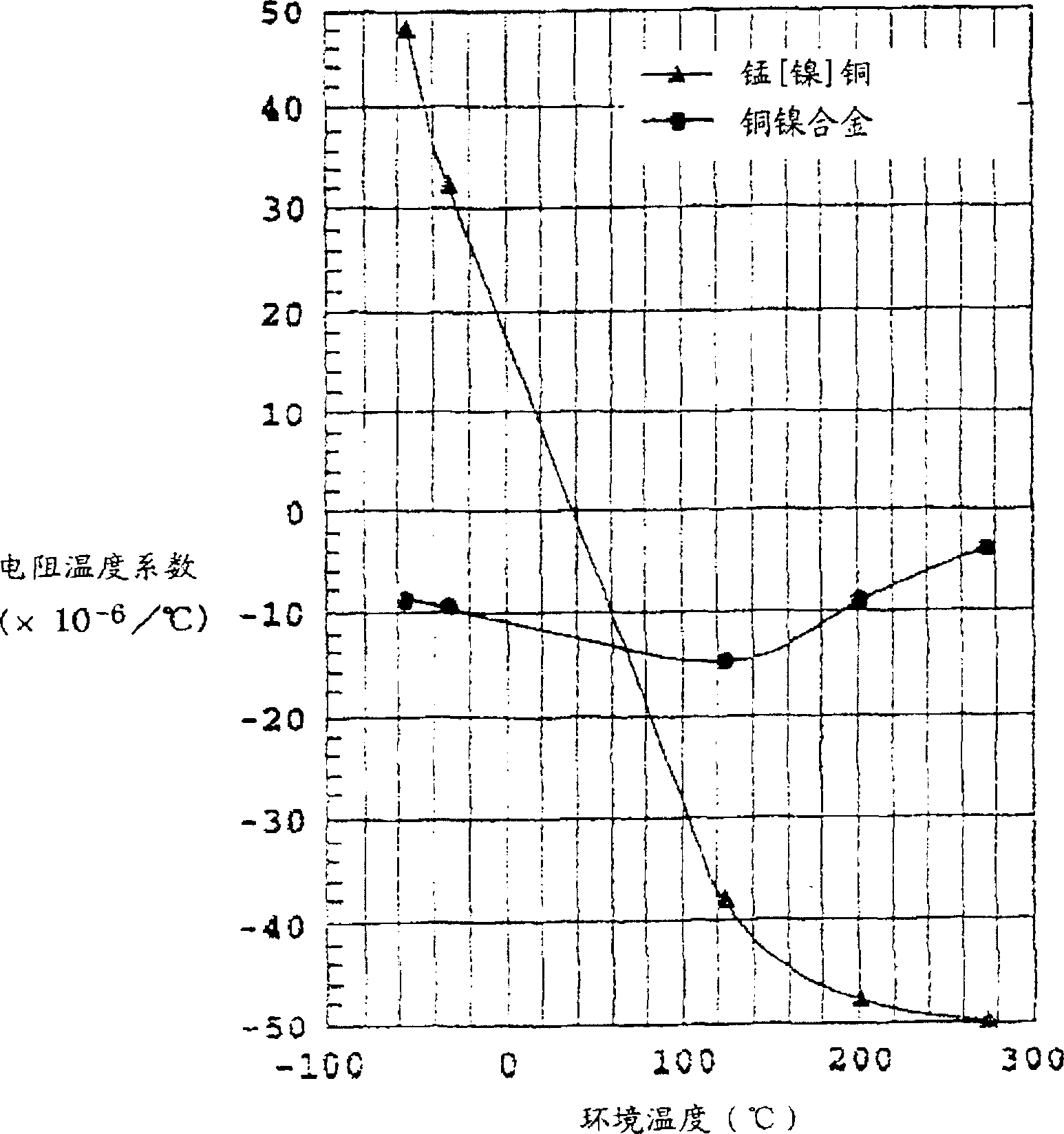

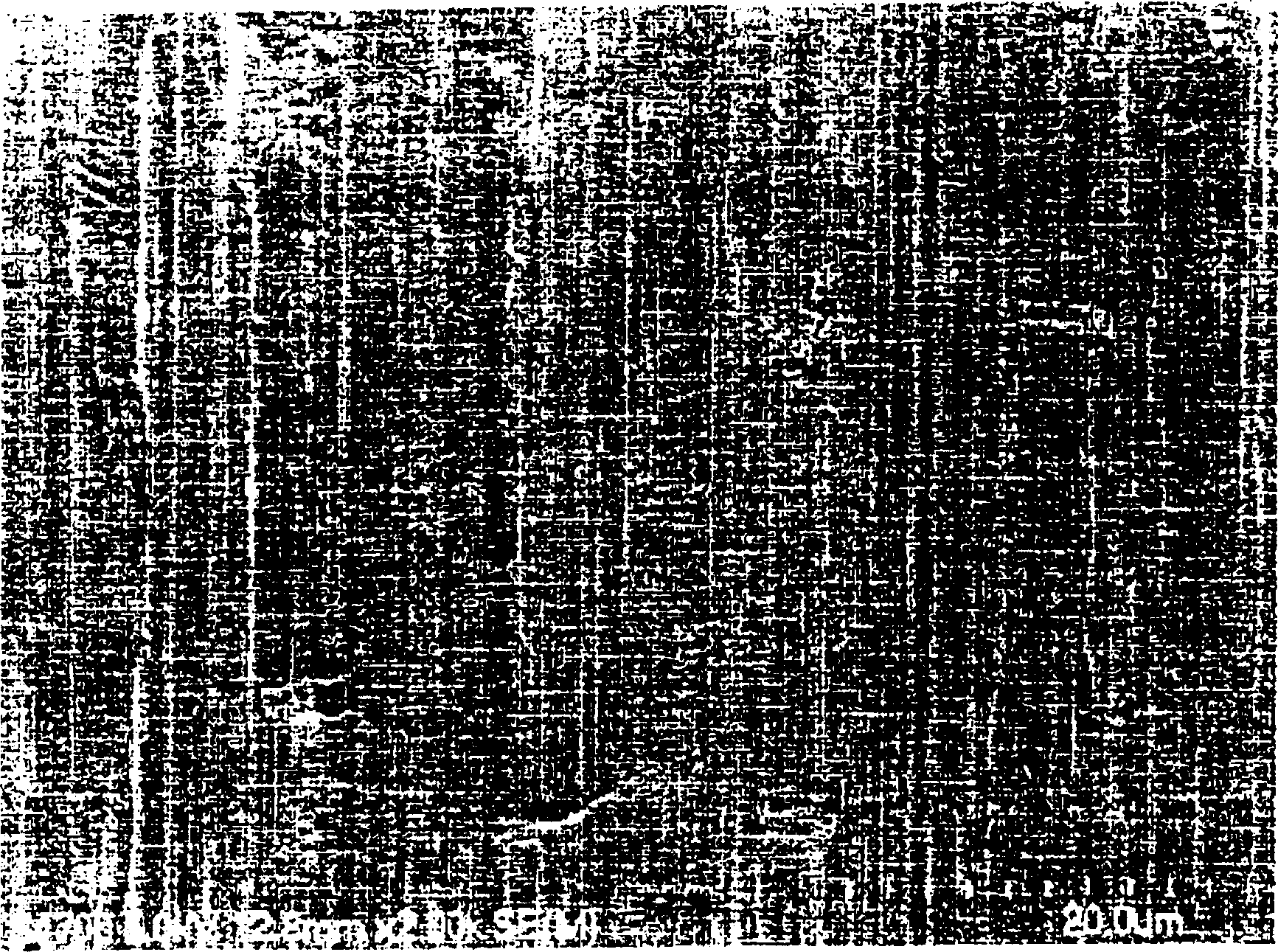

[0034] The above roughening process was carried out to roughen the surface of a copper-nickel alloy plate containing 54.5% by weight of copper, 43.7% by weight of nickel and 1.8% by weight of manganese and having a thickness of 0.2 mm. Figure 3 to Figure 8 The SEM photographs (diameter magnification 2,000) show the results of the roughening process in various methods.

[0035] image 3 is an SEM photograph of an untreated copper-nickel alloy plate. The copper-nickel alloy plate is rolled to have a smooth surface.

[0036] Figure 4 is a SEM photo of the surface of Sample 1 mechanically polished with #320 nonwoven fabric. The surface, although slightly textured, was not roughened.

[0037] Figure 5 is an SEM photograph of the surface of Sample 2 electropolished using chromic acid. Like Sample 1, the surface of the copper-nickel alloy plate was not roughened.

[0038] Figure 6 is an SEM photograph of the surface of Sample 3 roughened by a nitrous acid etchant. Forms ...

Embodiment approach 2

[0046] For the laminated board produced in Embodiment 1, the thickness of the insulating resin layer was changed, and the breakdown voltage thereof was measured. Table 2 lists the measurement results. It can be seen from Table 2 that when the thickness of the insulating resin layer 3 is 50 microns or more, the dielectric strength (breakdown voltage) required for the resistor can be achieved.

[0047] Thickness (micron)

[0048] According to the present invention, using a resistance alloy plate made of a copper-nickel alloy, such a resistor can be used in a power conversion device such as an inverter. The invention also manufactures a resistor for detecting current with high precision, the resistance of which will not change obviously with the change of temperature. Also, roughening the surface of the copper-nickel alloy by an organic acid etchant can improve the bonding strength between it and the insulating resin layer containing a large amount of inorganic filler....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com