Silicon-aluminium-silicon structure micro machinery processing method of full dry method

A technology of micromachining and silicon structure, applied in microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of reduced processing yield, complicated manufacturing process, high temperature treatment, etc., and achieves low manufacturing cost and operation. Simple process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

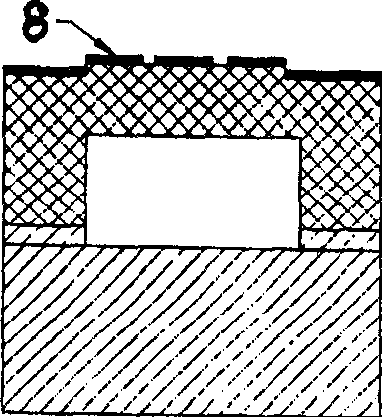

[0024] (1) Adopt commercially available general-purpose double-sided polished P-type single crystal silicon wafer 1 and double-sided polished N-type single crystal silicon wafer 2, both of which have a thickness of 280 μm to 320 μm, and the thickness of the embodiments is 300 μm, such as Picture 1-1 , 1-2.

[0025] (2) Coating a layer of positive AZ1450 type photoresist 3 on the front side of the N-type monocrystalline silicon wafer 2, the thickness of the photoresist 3 is 2 μm, such as Figure 1-3 .

[0026] (3) photoresist 3 is carried out to the photoresist 3 on the front side of the N-type single crystal silicon wafer 2 with a commercially available general-purpose photolithography machine, and the pattern window of the alignment mark 4 of the microstructure 9 is formed on the front side of the N-type single crystal silicon wafer 2, Such as Figure 1-4 .

[0027] (4) Using the photoresist 3 as a mask, use a general reactive ion etching machine to etch the silicon on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com