Method for preparing titanium dioxide film under room temperature

A titanium dioxide and thin film technology, which is applied in the field of preparing titanium dioxide thin films, achieves the effects of simple and easy method, widened selection range and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

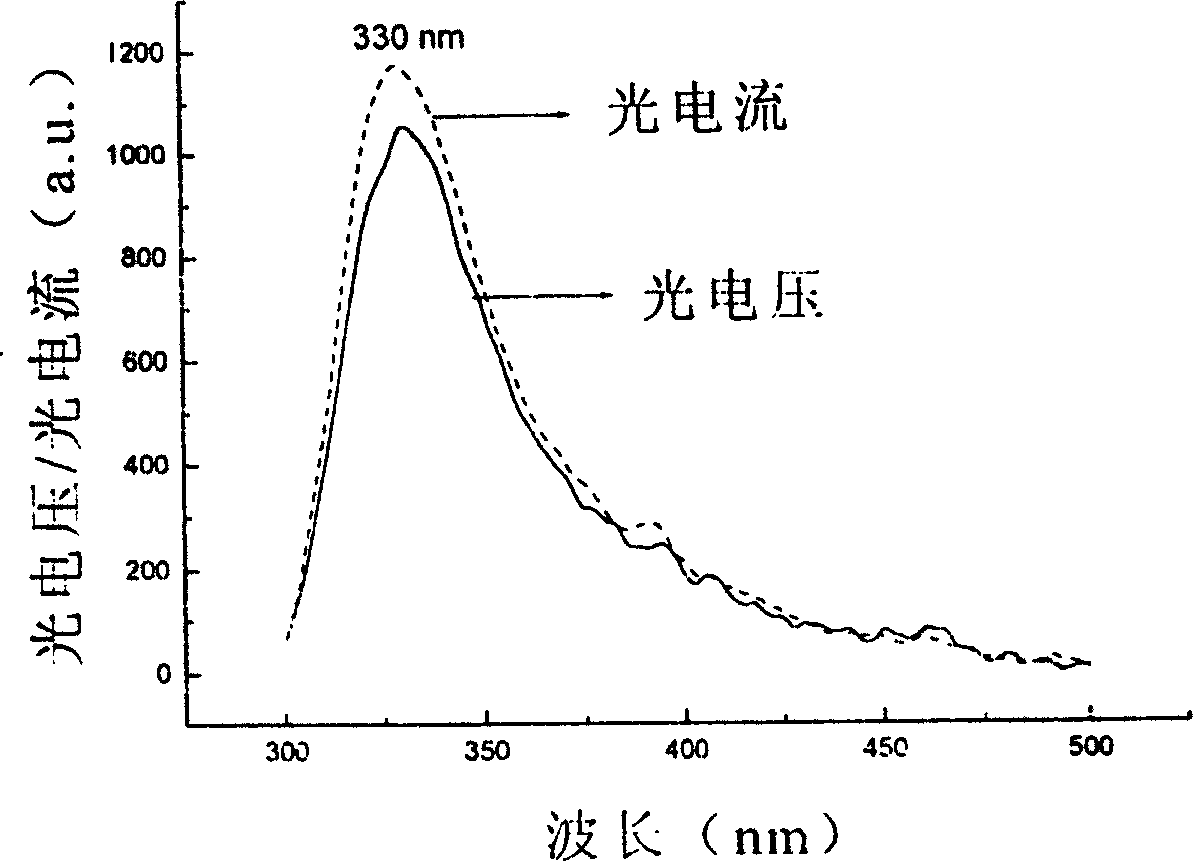

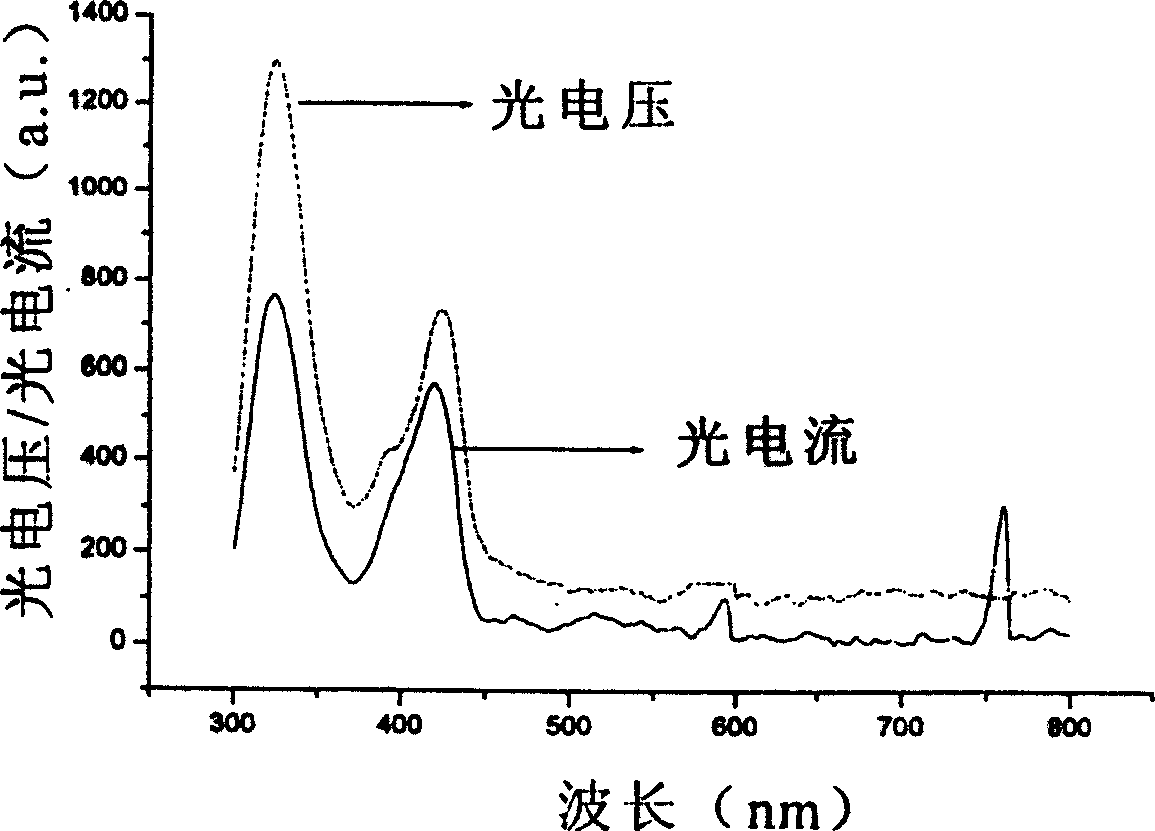

[0029] After cleaning the conductive glass substrate, dry it with nitrogen gas, place it on the sample holder of the sputtering instrument, use pure titanium as the target material, and take it out after sputtering for 230 seconds. At this time, a layer of metal titanium is coated on the conductive substrate. membrane. Using 1M nitric acid solution as the electrolyte solution, the voltage is 15V, and the current is controlled at 0.1mA-1A to electrolyze the film to obtain anatase TiO with nano-scale microporous structure. 2 film, it can be seen that the porous film is made of TiO 2 Composed of nano-scale particles, the size of the micropores is about 50-200nm and the appearance is as attached figure 1 . This film has photoelectric response, as attached figure 2 . The nanoscale microporous TiO 2 Thin films can be efficiently combined with dyes to form dye-sensitized TiO 2 Thin film electrode, its photoelectric response spectrum as attached image 3 .

Embodiment 2

[0031] After cleaning the conductive glass substrate, dry it with nitrogen gas, place it on the sample holder of the sputtering instrument, use pure titanium as the target material, and take it out after sputtering for 230 seconds. At this time, a layer of metal titanium is coated on the conductive substrate. membrane. Using 1M sulfuric acid solution as the electrolyte solution, the voltage is 15V, and the current is controlled at 0.1mA-1A to electrolyze the film to obtain anatase TiO with nano-scale microporous structure. 2 Thin film, this film has photoelectric response. The nanoscale microporous TiO 2 Thin films can be efficiently combined with dyes to form dye-sensitized TiO 2 thin film electrodes.

Embodiment 3

[0033] After cleaning the conductive glass substrate, dry it with nitrogen gas, place it on the sample holder of the sputtering instrument, use pure titanium as the target material, and take it out after sputtering for 200 seconds. At this time, a layer of metal titanium is coated on the conductive substrate. membrane. Using 1M nitric acid solution as the electrolyte solution, the voltage is 15V, and the current is controlled at 0.1mA-1A to electrolyze the membrane to obtain TiO with nano-scale microporous structure. 2 Thin film, this film has photoelectric response. The nanoscale microporous TiO 2 Thin films can be efficiently combined with dyes to form dye-sensitized TiO 2 thin film electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com