Preparing dye sensitized nanocrystalline semiconductor solar cell optical anode using electrical spinning method

A solar cell and dye sensitization technology, which is applied in the field of dye-sensitized solar cell material preparation, can solve the problems that dye-sensitized porous nanocrystalline semiconductor solar cell photoanodes have not been reported, and achieve easy operation and control, good repeatability, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 10 milliliters of the precursor isopropyl titanate of titanium dioxide are dropped into 60 milliliters of water, obtain titanium dioxide sol, then add PVA0.1 gram and sodium dodecylbenzene sulfonate 0.1 milliliter in 10 grams of titanium dioxide sols, At the same time, 0.2 g of acetylacetone was added and stirred for 2 hours to form a uniformly dispersed and stable titanium dioxide sol.

[0035] (2) The conductive glass is cleaned with tap water, secondary deionized water, acetone and ethanol successively, and dried;

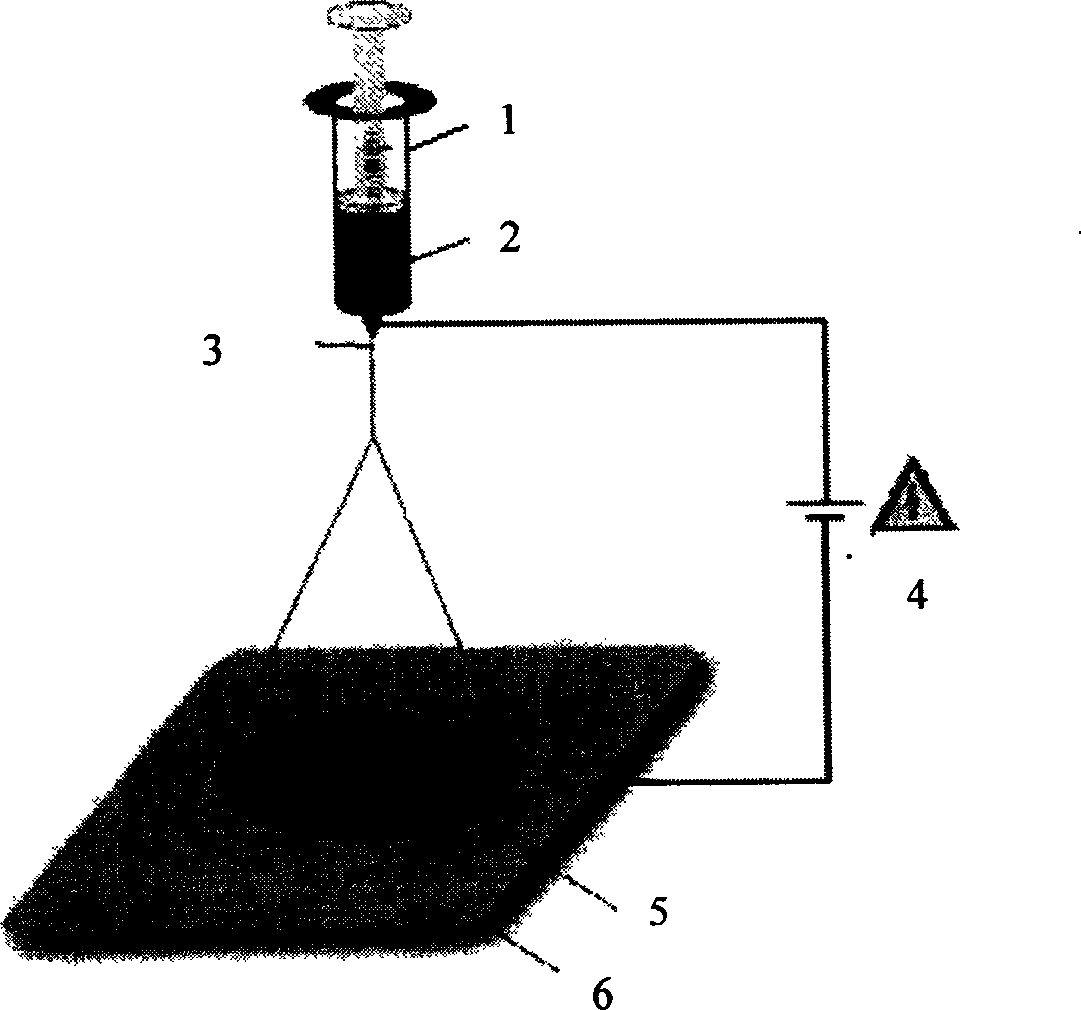

[0036] (3) Install the device for electrospinning, install the batching port on the liquid container, put the nanocrystalline semiconductor sol described in step (1) into the liquid container, then connect the high voltage generator to the material spray port, and connect the conductive The glass (i.e. receiver) is placed under the nozzle and grounded.

[0037] (4) Turn on the high-voltage generator described in step (3), under the action of electric...

Embodiment 2

[0040] (1) Drop 10 milliliters of isopropyl titanate, a precursor of titanium dioxide, into 100 milliliters of water to form a titanium dioxide sol, then add 0.2 grams of PVA and 0.1 milliliters of dodecylbenzenesulfonic acid to 10 grams of titanium dioxide sol, and add 0.1 g of acetylacetone was stirred for 2 hours to form a uniformly dispersed and stable titanium dioxide sol.

[0041] (2) The conductive glass is cleaned with tap water, secondary deionized water, acetone and ethanol successively, and dried;

[0042] (3) Install the device for electrospinning, install the batching port on the liquid container, put the nanocrystalline semiconductor sol described in step (1) into the liquid container, then connect the high voltage generator to the material spray port, and connect the conductive The glass (i.e. receiver) is placed under the nozzle and grounded.

[0043] (4) Turn on the high-voltage generator described in step (3), under the action of electric field force, the se...

Embodiment 3

[0046] (1) 10 milliliters of isopropyl titanate, a precursor of titanium dioxide, is dropped into 30 milliliters of water to form a titanium dioxide sol, then add 0.3 grams of PVA and 0.05 milliliters of dodecylbenzenecyclonic acid in 10 grams of titanium dioxide sol, and stir for 2 After hours, a uniformly dispersed and stable titanium dioxide sol was formed.

[0047] (2) The conductive glass is cleaned with tap water, secondary deionized water, acetone and ethanol successively, and dried;

[0048] (3) Install the device for electrospinning, install the batching port on the liquid container, put the nanocrystalline semiconductor sol described in step (1) into the liquid container, then connect the high voltage generator to the material spray port, and connect the conductive The glass (i.e. receiver) is placed under the nozzle and grounded.

[0049] (4) Turn on the high-voltage generator described in step (3), under the action of electric field force, the semiconductor sol in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com