Method for preparing ultraviolet photocurable coating

A technology for curing coatings and production methods, which is applied in the direction of coatings, etc., and can solve the problems of decreased physical and chemical performance indicators of paint film adhesion, adverse effects of construction environment, and reduced curing speed, and achieve excellent construction performance, good construction performance, and fast curing speed. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a detailed description of an embodiment:

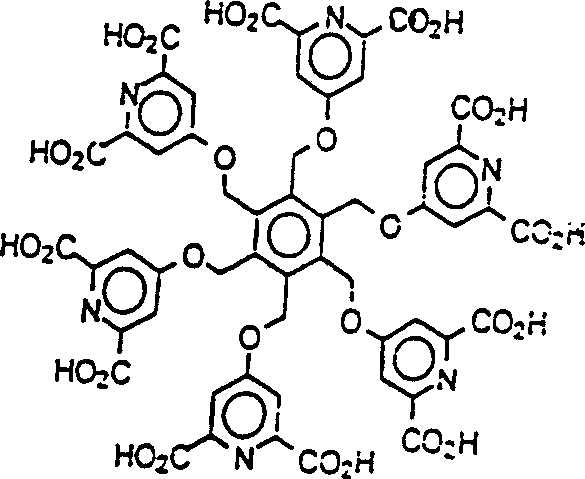

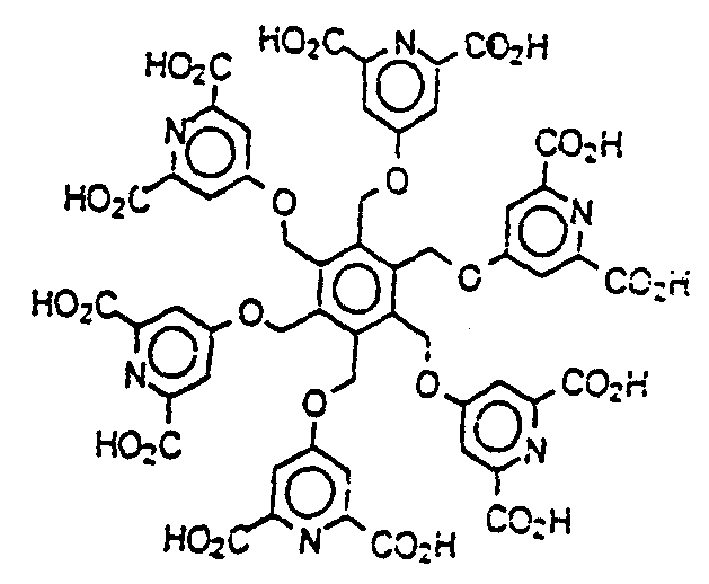

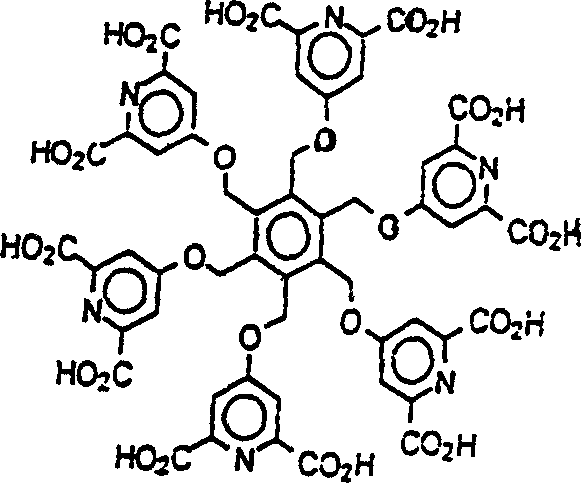

[0024] 1. Preparation of multi-branched oligomer B

[0025] Add 1248 grams of prepolymer (A), 1560 grams of glycidyl methacrylate (GMA), 1750 grams of xylene, and 31 grams of N,N-xylenebenzylamine into the reaction flask. Vacuum and fill with nitrogen are repeated 5 times. Under the protection of nitrogen, the temperature of the reaction system was gradually controlled at 135°C. After 8.5 hours of reaction, the temperature was lowered to room temperature. The reaction product was washed 4 times with methanol. The precipitate was vacuum dried at a drying temperature of 30-40°C to a constant weight. , The multi-branched oligomer B that can be cured by ultraviolet light is prepared.

[0026] 2. Preparation of UV-curable coatings

[0027] Take 450 grams of multi-branched oligomer B, 180 grams of linear acrylic acrylate oligomer, 140 grams of propoxylated neopentyl glycol diacrylate, and 85 grams of ethoxylated trimethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com