Monocell test fixture with temperature partition setting and test method thereof

A technology of temperature partition and test fixture, applied in the direction of measuring electricity, measuring device, measuring electrical variables, etc., can solve the problems such as solving the influence of fixture temperature, difficult to repeat specific tests, complex operating conditions of the stack, etc. The experimental cost is small, the change is convenient, and the effect of improving the performance of the stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

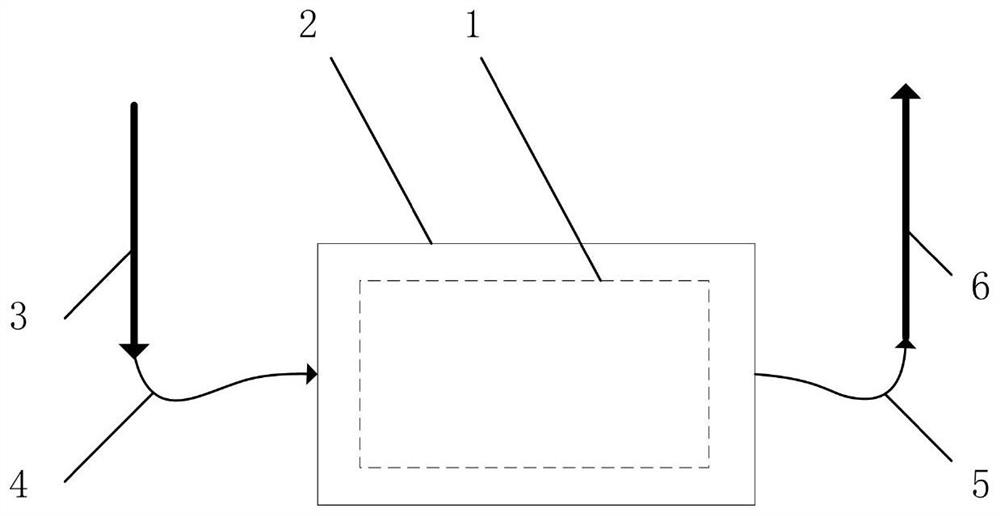

[0039] see Figure 1 to Figure 4 ,in figure 1 , Figure 4 It is a schematic diagram of the basic structure of the present invention. The fixture generally uses a press or a bolt to encapsulate the single cell structure, which is a conventionally known technology, and the encapsulation is not described in detail in the figure. Coolant flow control and temperature detection at the inlet and outlet are not shown in the attached drawings for simplicity of illustration.

[0040] The single cell 1 to be tested is located in a fixture 2, which is a set of conventional devices for fixing the single cell 1 and its partition detector 11, which is located between the single cell 1 and the cooler 7, and is located in the single cell 1. Both sides or one side of the detector 11 , that is, the partition detector 11 can be arranged on one side or both sides at the same time.

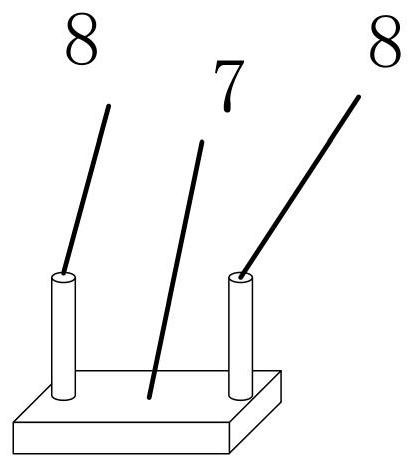

[0041] The cooler 7 is a rectangular heat-conducting metal shell, and there are two quick-plugs 8 of the cooler'...

Embodiment 2

[0047] The present invention can choose between the coolers 7 in series or individually controlled.

[0048] When using independent control, the temperature difference between each inlet and outlet should be within 1°C, preferably within 0.5°C, and more preferably within 0.2°C, that is, the actual measure is to stabilize the inlet temperature and increase the flow in parallel to establish a temperature difference in the area where the cooler is located. Temperature stability and repeatability.

[0049] When a series connection is used, it is preferable to simulate the cooling liquid flow pattern of the specific application, eg, co-current or counter-current with hydrogen, or serpentine series connection, and the outflow temperature simulates the cooling liquid outlet temperature of the application. This method can reduce the quantity of temperature control fluid of the cooling liquid temperature control device, and can reduce the investment cost of peripheral fluid temperature...

Embodiment 3

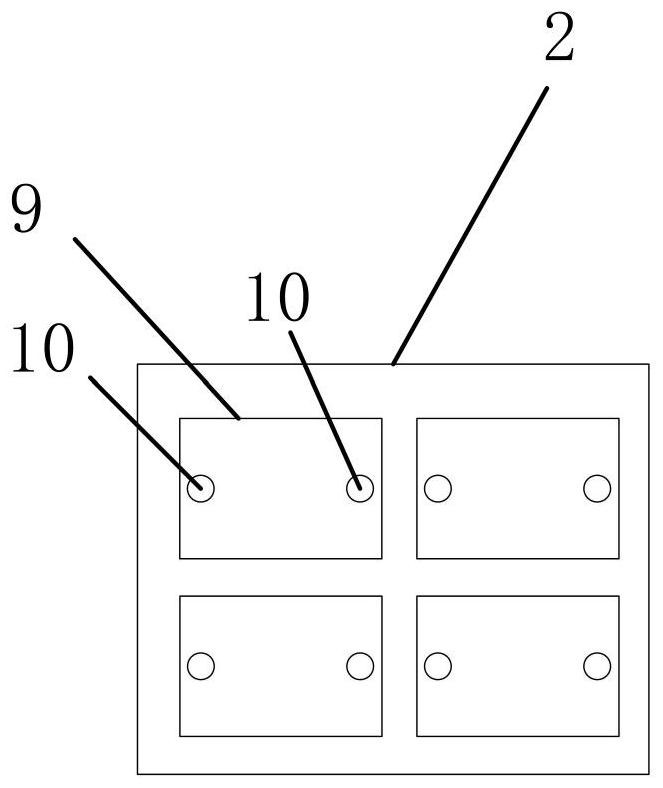

[0052] see Figure 5 , the parallel flow cooling structure in the short direction of the pole plate, showing the top view structure of the upper related connection of the one-sided clamp.

[0053] The cooler 7 sandwiched between the single cell 1 and the clamp 2 has the same inflow coolant conditions, ie the same temperature, unidirectional parallel cooling flow, resulting in simulated operating conditions with such a cooling layout. A similar fluid layout can be simulated, with coolant communicating on opposite sides of the long sides of the cell, perpendicular to the fuel and oxidant flow fields.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com