Wear-resistant catalyst coating for ceramic filter tube

A catalyst coating and ceramic technology, applied in the field of denitration catalysts, can solve the problems of low compressive strength, unsatisfactory denitration effect, and high brittleness, so as to improve mechanical properties and wear resistance, improve catalytic destocking effect, and increase growth rate. The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

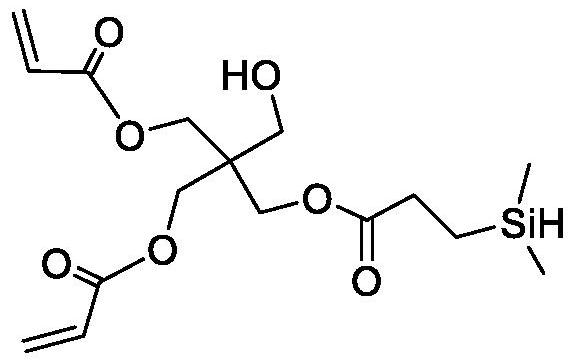

[0033] Preparation of branching agent:

[0034] After mixing 0.1mol pentaerythritol triacrylate and 60mL tetrahydrofuran, heat to reflux, and maintain reflux with condensed water control system, add platinum-carbon catalyst (platinum loading mass fraction is 5%), and slowly dropwise add 40mL containing 0.mol dihydrogen under stirring. The tetrahydrofuran solution of methylchlorosilane, after the dropwise addition was complete, continued to reflux for 4h, stopped the reaction, filtered, and the filtrate was cooled and evaporated under reduced pressure to obtain a branching agent, wherein the added mass of platinum was pentaerythritol triacrylate, dimethyl 0.2% of the total mass of chlorosilanes.

Embodiment 2

[0036] After mixing 0.1mol pentaerythritol triacrylate and 60mL tetrahydrofuran, heat to reflux, and maintain reflux with condensed water control system, add platinum carbon catalyst (platinum loading mass fraction is 5%), and slowly dropwise add 40mL containing 0.98mol dimethyl methacrylate under stirring. After the tetrahydrofuran solution of chlorosilane was added dropwise, the reflux reaction was continued for 7h, the reaction was stopped, filtered, and the filtrate was cooled and evaporated under reduced pressure to obtain a branching agent, wherein the added mass of platinum was pentaerythritol triacrylate, dimethyl chloride 0.6% of the total mass of silane.

Embodiment 3

[0038] Preparation of grafting agent:

[0039] After mixing 0.1 mol of areyl silyl methyl biscarbborane and 60 mL of tetrahydrofuran, under nitrogen protection and ice-water bath, slowly dropwise add 0.2 mol of n-butyllithium hexane solution (the mass fraction of n-butyllithium is 15%) ), after the addition, the temperature was raised to room temperature and the reaction was stirred for 2 hours, and then 30 mL of a tetrahydrofuran solution containing 0.2 mol of dimethylvinylchlorosilane was added dropwise. After the addition was complete, the reaction was stirred at room temperature for 18 hours, and the reaction was stopped. After quenching, the organic layer was extracted several times with ether, washed with deionized water, dried over anhydrous magnesium sulfate, filtered, and rotary evaporated under reduced pressure to obtain the grafting agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com