Green fluorophlogopite fluorescent powder with high quantum yield as well as preparation method and application of green fluorophlogopite fluorescent powder

A fluorophlogopite and high quantum technology, which is applied in the field of green fluorophlogopite phosphor and its preparation, can solve the problems of poor fingerprint development effect and low fluorescence intensity, and achieves low selectivity, broad application prospect and obvious transition area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

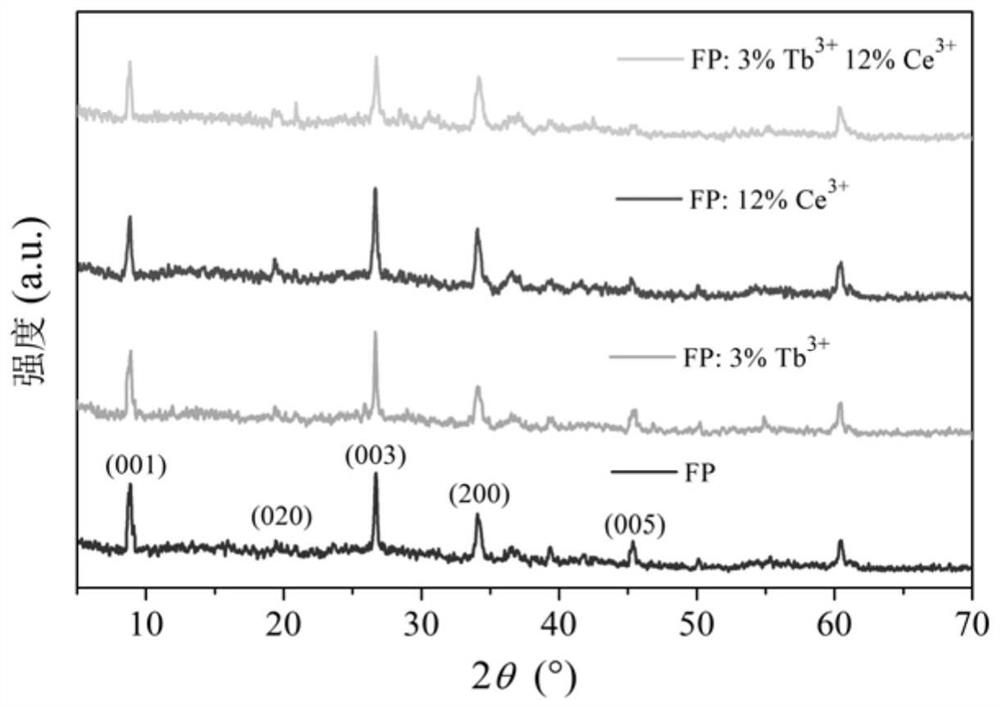

[0042] An embodiment of the present invention provides a method for preparing a high quantum yield green fluorophlogopite phosphor, which at least includes the following steps:

[0043] Step 1. Put 0.1307g K 2 SiF 6 , 0.1435g MgO, 0.0581g Al 2 O 3 , 0.1783g SiO 2 , 0.0067gTb 4 O 7 and 0.0246g CeO 2 After mixing, fully grind in agate mortar for 20min to obtain mixed solid powder;

[0044] Step 2. Put the mixed solid powder in a corundum crucible, under a nitrogen atmosphere, heat up to 1050°C at a rate of 5°C / min in a tube furnace, calcinate for 5.0h, and drop to room temperature at a rate of 3°C / min , grinding to obtain the high quantum yield green fluorophlogopite phosphor (FP:3%Tb 3+ ,12% Ce 3+ phosphor).

Embodiment 2

[0046] An embodiment of the present invention provides a method for preparing a high quantum yield green fluorophlogopite phosphor, which at least includes the following steps:

[0047] Step 1. Put 0.1285g K 2 SiF 6 , 0.1565g MgO, 0.0628g Al 2 O 3 , 0.1751g SiO 2 , 0.0045gTb 4 O 7 and 0.0182g CeO 2 After mixing, fully grind in agate mortar for 20min to obtain mixed solid powder;

[0048] Step 2. Put the mixed solid powder in a corundum crucible, under a nitrogen atmosphere, heat up to 1030°C at a rate of 4°C / min in a tube furnace, calcine for 5.0h, and drop to room temperature at a rate of 2°C / min , grinding to obtain the high quantum yield green fluorophlogopite phosphor (FP: 2% Tb 3+ ,9% Ce 3+ phosphor).

Embodiment 3

[0050] An embodiment of the present invention provides a method for preparing a high quantum yield green fluorophlogopite phosphor, which at least includes the following steps:

[0051] Step 1. Put 0.1405g K 2 SiF 6 , 0.1449g MgO, 0.0576g Al 2 O 3 , 0.1916g SiO 2 , 0.0095gTb 4 O 7 and 0.0242g CeO 2 After mixing, fully grind in agate mortar for 20min to obtain mixed solid powder;

[0052] Step 2. Put the mixed solid powder in a corundum crucible, under nitrogen atmosphere, heat up to 1070°C at a rate of 6°C / min in a tube furnace, calcinate for 4.5h, and drop to room temperature at a rate of 4°C / min , grinding to obtain the high quantum yield green fluorophlogopite phosphor (FP:4%Tb 3+ ,11% Ce 3+ phosphor).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com