Formaldehyde-free flame-retardant waterproof glue and preparation method thereof

A technology of waterproof glue and flame retardant powder, applied in the field of waterproof glue, can solve the problems of poor waterproof, non-flame retardant and deformation of MDI glue, and achieve the effects of low cost, good mechanical properties and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

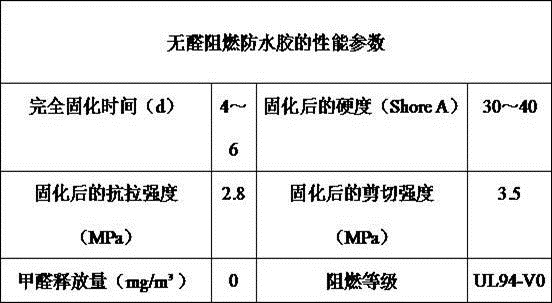

Image

Examples

Embodiment 1

[0023] A flame -free flame -retardant waterproof glue, with the quality portion, the composition and content of each composition are as follows:

[0024] 20 parts of biomass protein, 5 water -based polymerization, 3 parts of water glass, 1 borosa, 3 parts of polycurco, 1 flame retardant powder, 0.2 preservatives, and 0.1 thickeners.

[0025] Among them, the composition of biomass protein is gramophone;

[0026] Among them, flame retardant is aluminum composite flame retardant powder;

[0027] Among them, preservatives are cadon preservatives, and thickeners are acrylic thickeners.

Embodiment 2

[0029] A flame -free flame -retardant waterproof glue, with the quality portion, the composition and content of each composition are as follows:

[0030] 22 parts of biomass protein, 7 parts of water -based polymer isopase, 6 parts of water glass, 2 parts of borax, 3.5 parts of polycurco, 2.5 flame retardant powder, 0.3 propeller, and 0.4 thickeners.

[0031] Among them, the composition of biomass protein is gramophone;

[0032] Among them, flame retardant is aluminum composite flame retardant powder;

[0033] Among them, preservatives are cadon preservatives, and thickeners are acrylic thickeners.

Embodiment 3

[0035] A flame -free flame -retardant waterproof glue, with the quality portion, the composition and content of each composition are as follows:

[0036] 25 parts of biomass protein, 12 parts of water -based polymer isopase, 8 parts of water glass, 3 parts of borax, 5 parts of polyxane, 3 combustible powder, 0.4 preservatives and 0.5 thickeners.

[0037] Among them, the composition of biomass protein is gramophone;

[0038] Among them, flame retardant is aluminum composite flame retardant powder;

[0039] Among them, preservatives are cadon preservatives, and thickeners are acrylic thickeners.

[0040] The preparation method of a flame -free waterproof and waterproof glue provided by the above embodiments 1 to 3, including the following steps:

[0041] S1, pour the biomass protein and water -based polymer isocyanate into the mixer according to proportion, stir at high speed for 10 minutes to get a mixed raw material A;

[0042] S2, break the borax, grind it into powder, then add w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com