Environment-friendly deplating agent as well as preparation method and use method thereof

An environment-friendly, deplating technology, applied in the field of stripping agents, can solve the problems of long nickel stripping time, fast copper corrosion speed, and difficult to use in large quantities, and achieve the effect of wide source of raw materials, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

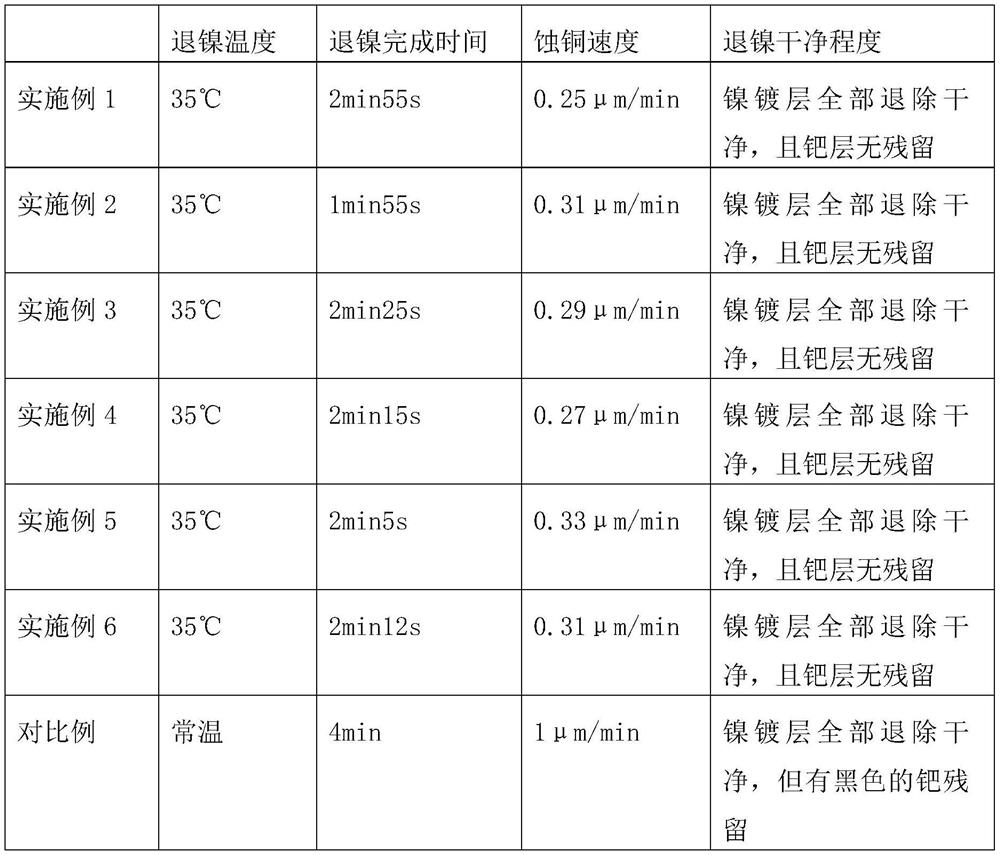

Examples

Embodiment 1

[0025] This embodiment discloses an environment-friendly stripping agent, and each liter of the environment-friendly stripping agent contains: 20 g of sodium persulfate, 100 mL of concentrated sulfuric acid, 2 g of ferric chloride hexahydrate, 0.005 g of wetting agent, and imidazole slow-release agent 1 g, 1 g of citric acid, and the solvent is water.

[0026] The mass fraction of concentrated sulfuric acid in this example is 98%.

[0027] The wetting agent in this example is PEG200.

[0028] The imidazole-based sustained-release agent in this embodiment is 2-thiobenzimidazole.

[0029] The solvent in this example is pure water.

[0030] The preparation method of the environment-friendly stripping agent in the present embodiment comprises the following steps:

[0031] S1, take by weighing the sodium persulfate, vitriol oil, ferric chloride hexahydrate, wetting agent, imidazole slow-release agent, citric acid, water of formula amount;

[0032] S2, take half the volume of wa...

Embodiment 2

[0034] This embodiment discloses an environment-friendly stripping agent. Each liter of the environment-friendly stripping agent contains: 100 g of sodium persulfate, 300 mL of concentrated sulfuric acid, 10 g of ferric chloride hexahydrate, 0.1 g of wetting agent, and imidazole slow-release agent 10g, citric acid 10g, and the solvent is water.

[0035] The mass fraction of concentrated sulfuric acid in this example is 98%.

[0036] The wetting agent in this embodiment is any one of PEG600.

[0037] The imidazole-based sustained-release agent in this embodiment is 2-thiobenzimidazole.

[0038] The solvent in this example is pure water.

[0039] The preparation method of the environment-friendly stripping agent in the present embodiment comprises the following steps:

[0040] S1, take by weighing the sodium persulfate, vitriol oil, ferric chloride hexahydrate, wetting agent, imidazole slow-release agent, citric acid, water of formula amount;

[0041] S2, take half the volum...

Embodiment 3

[0043] This embodiment discloses an environment-friendly stripping agent. Each liter of the environment-friendly stripping agent contains: 30 g of sodium persulfate, 150 mL of concentrated sulfuric acid, 2 g of ferric chloride hexahydrate, 0.01 g of wetting agent, and imidazole slow-release agent 2g, citric acid 2g, and the solvent is water.

[0044] The mass fraction of concentrated sulfuric acid in this example is 98%.

[0045] The wetting agent in this example is PEG6000.

[0046] The imidazole-based sustained-release agent in this embodiment is 2-thiobenzimidazole.

[0047] The solvent in this example is pure water.

[0048] The preparation method of the environment-friendly stripping agent in the present embodiment comprises the following steps:

[0049] S1, take by weighing the sodium persulfate, vitriol oil, ferric chloride hexahydrate, wetting agent, imidazole slow-release agent, citric acid, water of formula amount;

[0050] S2, take half the volume of water, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com