ZTA ceramic net film modified nano powder metallurgy material and preparation method thereof

A technology of powder metallurgy and nano-powder, which is applied in the field of ZTA ceramic omentum modified nano-powder metallurgy materials and its preparation, can solve the problems of plastic toughness and damage tolerance reduction, achieve average particle size reduction, reduce stress concentration, The effect of multiple energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

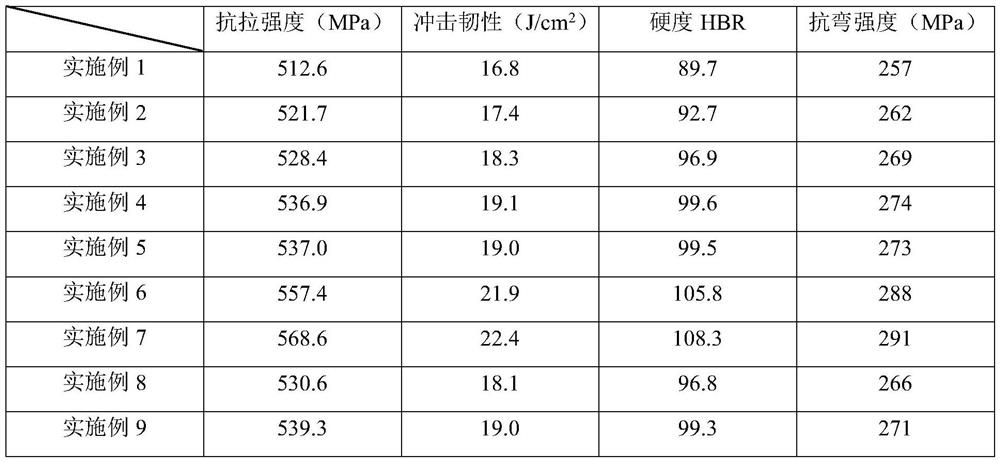

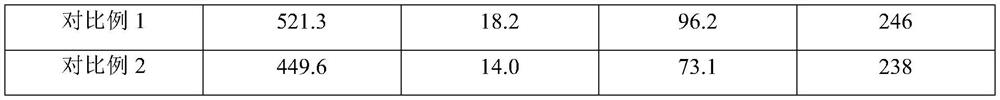

Examples

Embodiment 1

[0030] A preparation method of ZTA ceramic mesh membrane modified nano powder metallurgy material, comprising the following steps:

[0031] (1) Put the composite metal nano-powder into the mixer according to the proportion and evenly mix for 40min; the composite metal nano-powder includes the following components: nickel powder 0.4%, copper powder 0.5%, aluminum powder 0.3%, zinc stearate 0.75%, The balance of pre-alloyed iron powder; wherein, the pre-alloyed iron powder is a nickel-chromium-iron alloy, the content of nickel is 0.5wt%, and the content of chromium is 0.8wt%;

[0032] (2) Lay the composite metal nano-powder into a special forming press for powder metallurgy with a thickness of 0.2mm;

[0033] (3) Continue to lay a layer of ZTA ceramic mesh with a thickness of 0.05mm and a porosity of 38%;

[0034] (4) Lay a layer of composite metal nano-powder with a thickness of 0.2mm;

[0035] (5) Compression molding under 700MPa pressing force;

[0036] (6) vacuum sinterin...

Embodiment 2

[0045] A preparation method of ZTA ceramic mesh membrane modified nano powder metallurgy material, comprising the following steps:

[0046] (1) Put the composite metal nano-powder into the mixer according to the proportion and evenly mix for 40min; the composite metal nano-powder includes the following components: nickel powder 0.4%, copper powder 0.5%, aluminum powder 0.3%, zinc stearate 0.75%, The balance of pre-alloyed iron powder; wherein, the pre-alloyed iron powder is a nickel-chromium-iron alloy, the content of nickel is 0.5wt%, and the content of chromium is 0.8wt%;

[0047] (2) Lay the composite metal nano-powder into a special forming press for powder metallurgy with a thickness of 0.2mm;

[0048] (3) Continue to lay a layer of ZTA ceramic mesh with a thickness of 0.1mm and a porosity of 38%;

[0049] (4) Lay a layer of composite metal nano-powder with a thickness of 0.2mm;

[0050] (5) Compression molding under 700MPa pressing force;

[0051] (6) vacuum sintering...

Embodiment 3

[0060] A preparation method of ZTA ceramic mesh membrane modified nano powder metallurgy material, comprising the following steps:

[0061] (1) Put the composite metal nano-powder into the mixer according to the proportion and evenly mix for 40min; the composite metal nano-powder includes the following components: nickel powder 0.4%, copper powder 0.5%, aluminum powder 0.3%, zinc stearate 0.75%, The balance of pre-alloyed iron powder; wherein, the pre-alloyed iron powder is a nickel-chromium-iron alloy, the content of nickel is 0.5wt%, and the content of chromium is 0.8wt%;

[0062] (2) Lay the composite metal nano-powder into a special forming press for powder metallurgy with a thickness of 0.2mm;

[0063] (3) Continue to lay a layer of ZTA ceramic mesh with a thickness of 0.2mm and a porosity of 38%;

[0064] (4) Lay a layer of composite metal nano-powder with a thickness of 0.2mm;

[0065] (5) Compression molding under 700MPa pressing force;

[0066] (6) vacuum sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com