Production method for producing butyric anhydride through dividing wall reaction rectification

A technology for the production of butyric anhydride and production methods, applied in the direction of carboxylic anhydride preparation, chemical instruments and methods, carboxylate preparation, etc., can solve the problems of many by-products, large equipment investment, and low purity of butyric anhydride products, and achieve energy saving The effect of saving energy consumption and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

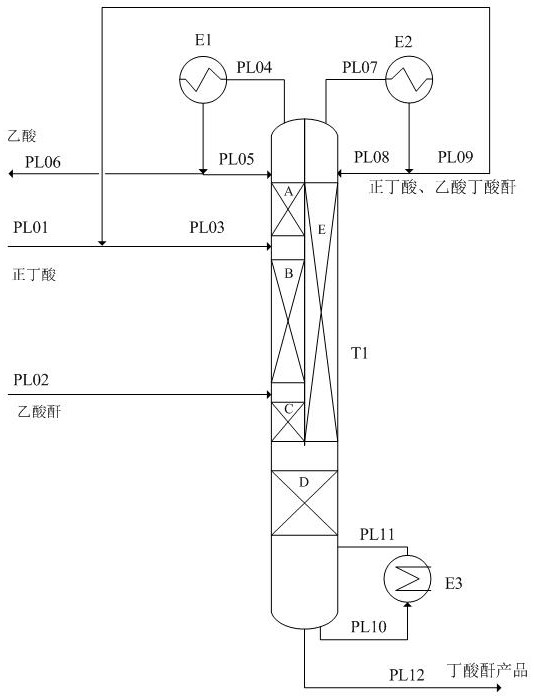

[0035] The partition wall reactive distillation column T1 is a packed column with a column diameter of 50mm, the column body and packing material are both 2205, the packing type is φ3×3 θ ring packing, the column height is 6.0m, and the theoretical plate number of rectifying section A is 18 , the number of theoretical plates in the reaction section B is 22, the number of theoretical plates in the stripping section C is 16, the number of theoretical plates in the rectifying section E of the auxiliary column is 38, the number of theoretical plates in the common stripping section D is 25, and the number of theoretical plates in the auxiliary column D is 25. The cross-sectional area ratio to the main tower is 0.4.

[0036] The n-butyric acid is fed from the upper feed pipe PL3 of the next-wall reactive distillation column T1 at a flow rate of 8.0g / min, wherein the flow rate of fresh n-butyric acid is 5.3g / min, and the flow rate of circulating n-butyric acid at the top of the auxili...

Embodiment 2

[0039] The partition wall reactive distillation column T1 is a packed column with a column diameter of 50mm, the column body and packing material are both 2205, the packing type is φ3×3 θ ring packing, the column height is 6.0m, and the theoretical plate number of rectifying section A is 18 , the number of theoretical plates in the reaction section B is 22, the number of theoretical plates in the stripping section C is 16, the number of theoretical plates in the rectifying section E of the auxiliary column is 38, the number of theoretical plates in the common stripping section D is 25, and the number of theoretical plates in the auxiliary column D is 25. The cross-sectional area ratio to the main tower is 0.4.

[0040] The n-butyric acid is fed from the upper feed pipe PL3 of the next-wall reactive distillation column T1 at a flow rate of 10.0g / min, wherein the flow rate of fresh n-butyric acid is 4.0g / min, and the flow rate of circulating n-butyric acid at the top of the auxil...

Embodiment 3

[0043] The partition wall reactive distillation column T1 is a packed column with a column diameter of 50mm, the column body and packing material are both 2205, the packing type is φ3×3 θ ring packing, the column height is 6.0m, and the theoretical plate number of rectifying section A is 18 , the number of theoretical plates in the reaction section B is 22, the number of theoretical plates in the stripping section C is 16, the number of theoretical plates in the rectifying section E of the auxiliary column is 38, the number of theoretical plates in the common stripping section D is 25, and the number of theoretical plates in the auxiliary column D is 25. The cross-sectional area ratio to the main tower is 0.4.

[0044] The n-butyric acid is fed from the upper feed pipe PL3 of the next-wall reactive distillation column T1 at a flow rate of 10.0g / min, wherein the flow rate of fresh n-butyric acid is 4.0g / min, and the flow rate of circulating n-butyric acid at the top of the auxil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com