Bismuth vanadate-based ceramic with tetragonal scheelite structure and high oxygen ion conductivity in medium-temperature zone and preparation method of bismuth vanadate-based ceramic

A bismuth vanadate-based ceramic, ionic conductivity technology, applied in cable/conductor manufacturing, oxide conductors, circuits, etc., can solve low safety, low chemical stability, wide application limitations of solid oxide fuel cell devices, etc. problem, to achieve the effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

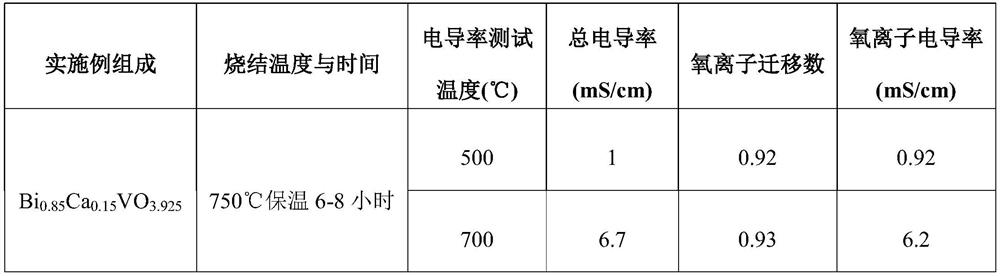

[0013] Table 1 shows specific embodiments of the present invention and their electrical conductivity. The preparation method is as described above. The phase analysis of the sintered ceramic sample is carried out by powder X-ray diffractometry. figure 1 It is the X-ray diffraction pattern of the example of the present invention, which shows that a single tetragonal scheelite mineral phase is formed, and the electrical conductivity of the ceramic is evaluated by an alternating current impedance analyzer.

[0014] The invention can be widely used in the manufacture of electronic devices such as electrolytes, oxygen sensors and oxygen permeable membranes for medium temperature region solid oxide fuel cells, and can meet the requirements of all solid oxide fuel cells, oxygen sensors and oxygen permeation membranes in the medium temperature region of 500-700°C. Technical needs for related energy, transportation and chemical products.

[0015] Table 1:

[0016]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com