Contraction-expansion nozzle, manufacturing method thereof, additive manufacturing equipment and method

A technology of additive manufacturing and nozzles, which is applied in the field of cold spray additive manufacturing, can solve the problems of limited material types, poor material performance, and high cost, and achieve simple process, improved hardness and corrosion resistance, and good material performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

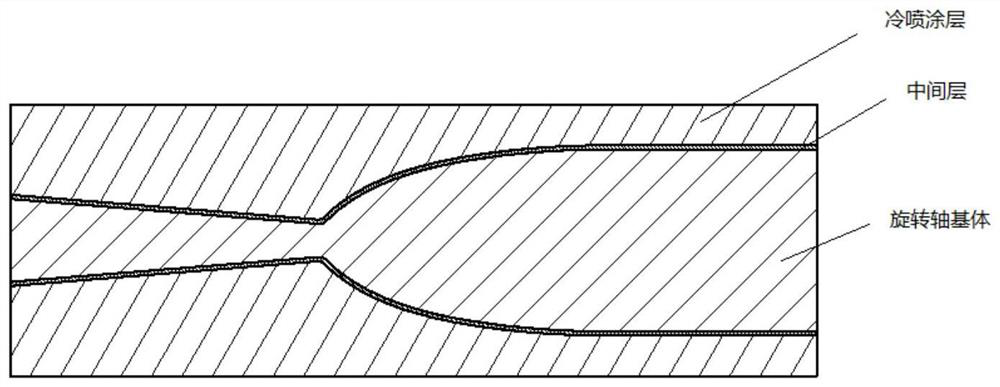

[0020] Some embodiments of the present invention provide a method for preparing a shrink-expand nozzle, which includes: adopting a cold spray method on a rotary shaft base for additive manufacturing of a shrink-expand nozzle required for additive manufacturing, wherein the pressure used for the cold spray is 2MPa~5MPa; use physical method or chemical method to remove the base of the rotating shaft.

[0021] Cold spraying is a kind of rapid prototyping technology. Its main principle is to heat solid powder particles (below the melting temperature) and accelerate them to supersonic speed to collide with the matrix, and then deposit and form a coating through strong plastic deformation. Compared with traditional thermal spraying, this technology does not need to melt the sprayed metal powder particles, so there is no physical and chemical reaction involved in the whole process, and it is a solid-state additive preparation technology. Cold spraying can spray a variety of materials...

Embodiment 1

[0048] The present embodiment provides a method for preparing a contraction-expansion nozzle, which specifically includes:

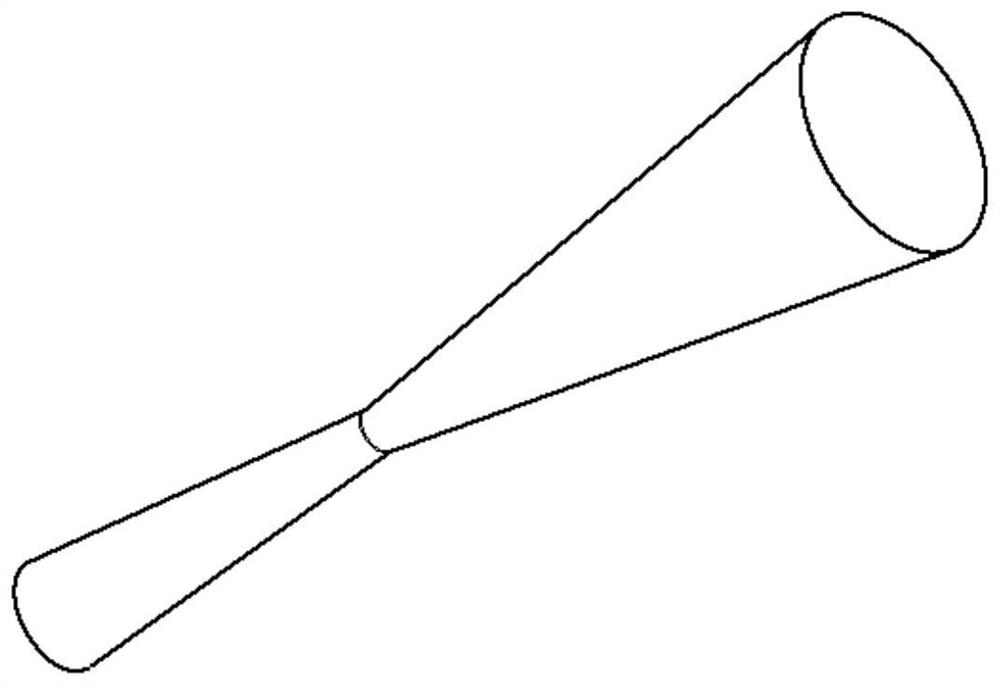

[0049] Select the base of the rotating shaft made of pure iron. The base of the rotating shaft is prepared by casting. The base of the rotating shaft is as follows: figure 1 shown.

[0050] The intermediate layer is prepared by cold spraying. The material of the intermediate layer is pure aluminum. The corresponding process parameters are: the spraying gas is nitrogen, the spraying pressure is 3.5MPa, the spraying temperature is 500℃, the powder feeding rate is 50g / min, and the nozzle scans The speed is 300mm / s, and the distance from the nozzle to the surface to be sprayed is 35mm.

[0051] After the preparation of the intermediate layer, copper was used as the shrink-expanding nozzle material, and the shrink-expanding nozzle was prepared by cold spraying. The amount of powder is 100g / min, the scanning speed of the nozzle is 400mm / s, and the distance f...

Embodiment 2

[0055] The present embodiment provides a method for preparing a contraction-expansion nozzle, which specifically includes:

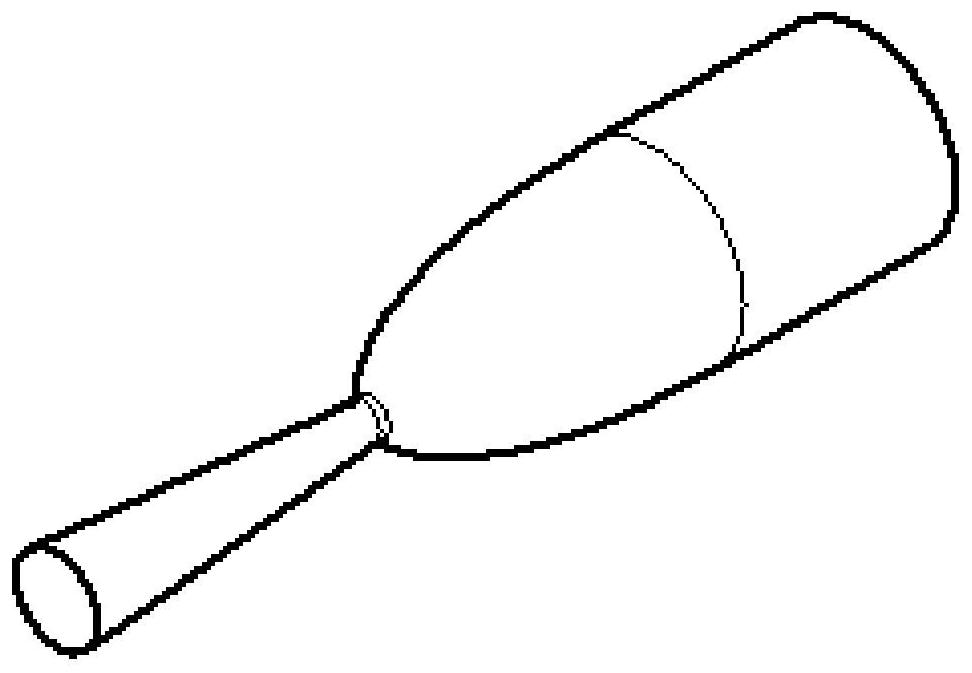

[0056] The rotating shaft base of pure aluminum material is selected. The rotating shaft base is prepared by casting. The rotating shaft base is as follows: figure 2 The bell-shaped, rotating shaft base shown is made of pure aluminum.

[0057] The intermediate layer is prepared by cold spraying. The material of the intermediate layer is pure aluminum. The corresponding process parameters are: the spraying gas is nitrogen, the spraying pressure is 4.5MPa, the spraying temperature is 450℃, the powder feeding rate is 60g / min, and the nozzle scans The speed is 350mm / s, and the distance from the nozzle to the surface to be sprayed is 30mm.

[0058] After the preparation of the intermediate layer, the shrink-expansion nozzle is made of tungsten carbide-nickel mixed powder material (the mixing ratio is 50:50 vol.%), and the shrink-expansion nozzle is prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com