High-strength aluminum alloy scalloped petal side hole electromagnetic flanging device and method

An aluminum alloy, high-strength technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of process optimization, low production efficiency, and high labor intensity of workers, and achieve single and easy control of process parameters, processing and Easy to repair and avoid the effect of substandard size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

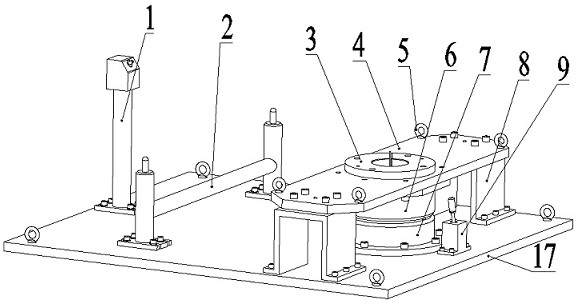

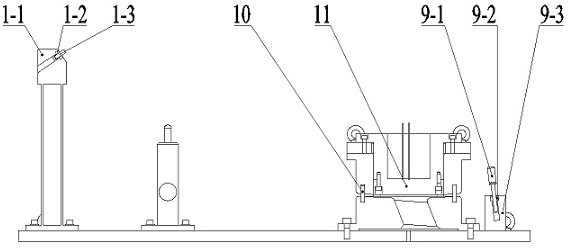

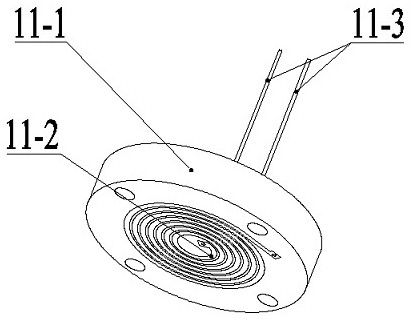

[0040]A high-strength aluminum alloy melon petal side hole electromagnetic flanging device includes a lower positioning base 1, a support frame 2, an upper positioning base 9, a bottom plate 17 and a melon petal side hole flanging mold, and the lower positioning base 1 includes: The lower positioning column 1-1, the first bushing 1-2 and the lower positioning pin 1-3; the upper positioning base 9 includes the second bushing 9-2, the upper positioning column 9-3 and the upper positioning pin 9- 1; the support frame 2, the lower positioning column 1-1 and the upper positioning column 9-3 are all fixed on the bottom plate 17 by screws; Ear 5, upper blanking die 6, forming die 7, column 8, upper positioning base 9, blanking positioning pin 10, forming coil 11, top pressing seat positioning pin 13 and pressing plate positioning pin 14, the forming die 7 passes through The screws are fixed on the bottom plate 17, the upper side blanking die 6 is fixed on the pressing plate 4 by scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com