Boron-nitrogen co-doped hard carbon material and preparation method thereof

A co-doping, hard carbon technology, applied in the preparation/purification of carbon, structural parts, electrical components, etc., can solve the problems of low battery discharge capacity, unfavorable lithium/sodium ion storage, large crystal layer spacing, etc. The process is simple, the discharge capacity and rate performance are improved, and the effect of improving the adsorption and storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a method for preparing a boron-nitrogen co-doped hard carbon material, comprising the following steps:

[0037] 1) obtain trisodium citrate, urotropine and boron-containing oxide, mix them evenly, and carry out carbonization reaction under protective atmosphere to obtain composite hard carbon material;

[0038] 2) The composite hard carbon material obtained in step 1) is taken out and washed with an acid solution, and the sodium borate salt by-products in the composite hard carbon material are eluted to obtain a loose and porous boron-nitrogen co-doped hard carbon material.

[0039] Boron doping is a p-type doping, which can effectively reduce the Fermi level of hard carbon materials and enhance the intercalation-extraction ability of metal ions; nitrogen doping can further improve the electrical conductivity of hard carbon materials; compared with single-atom doping The co-doping of boron atoms and nitrogen atoms not only maintains their ...

Embodiment 1

[0064] 1) Weigh trisodium citrate dihydrate, urotropine and boron oxide powder in a mass ratio of 1:1:0.5, and mix them evenly after grinding with a mortar in a fume hood;

[0065] 2) Put the above mixed powder into the ark, put it in a tube furnace, and put it in the Ar / H of 5% hydrogen. 2 Under the mixed atmosphere, the temperature is raised to 800°C at a heating rate of 3°C / min, and the carbonization reaction is carried out, and the carbonization reaction is performed for 2 hours to obtain a composite hard carbon material;

[0066] 3) After natural cooling, the composite hard carbon material prepared in step 2) is taken out from the tube furnace, firstly washed three times with a hydrochloric acid solution with a concentration of 0.1 mol / L, and then washed with anhydrous ethanol for two times. After cleaning, the samples were placed in a blast drying oven and dried at a temperature of 60° C. to obtain a boron-nitrogen co-doped hard carbon material 2 (number: HC-0.5) with a ...

Embodiment 2

[0069] 1) Weigh trisodium citrate dihydrate, urotropine and boric acid powder in a mass ratio of 1:1:1, and mix them evenly after grinding with a mortar in a fume hood;

[0070] 2) Put the above mixed powder into the ark, put it in a tube furnace, and put it in the Ar / H of 5% hydrogen. 2 Under the mixed atmosphere, the temperature is raised to 800°C at a heating rate of 3°C / min, and the carbonization reaction is carried out, and the carbonization reaction time is 2 hours to obtain a composite hard carbon material;

[0071] 3) After natural cooling, the carbon-based composite material prepared in step 2) is taken out from the tube furnace, firstly washed three times with a hydrochloric acid solution with a concentration of 0.1 mol / L, and then twice with anhydrous ethanol. After cleaning, the sample was placed in a blast drying oven and dried at 60° C. to obtain boron-nitrogen co-doped hard carbon material 3 (number: HC-1).

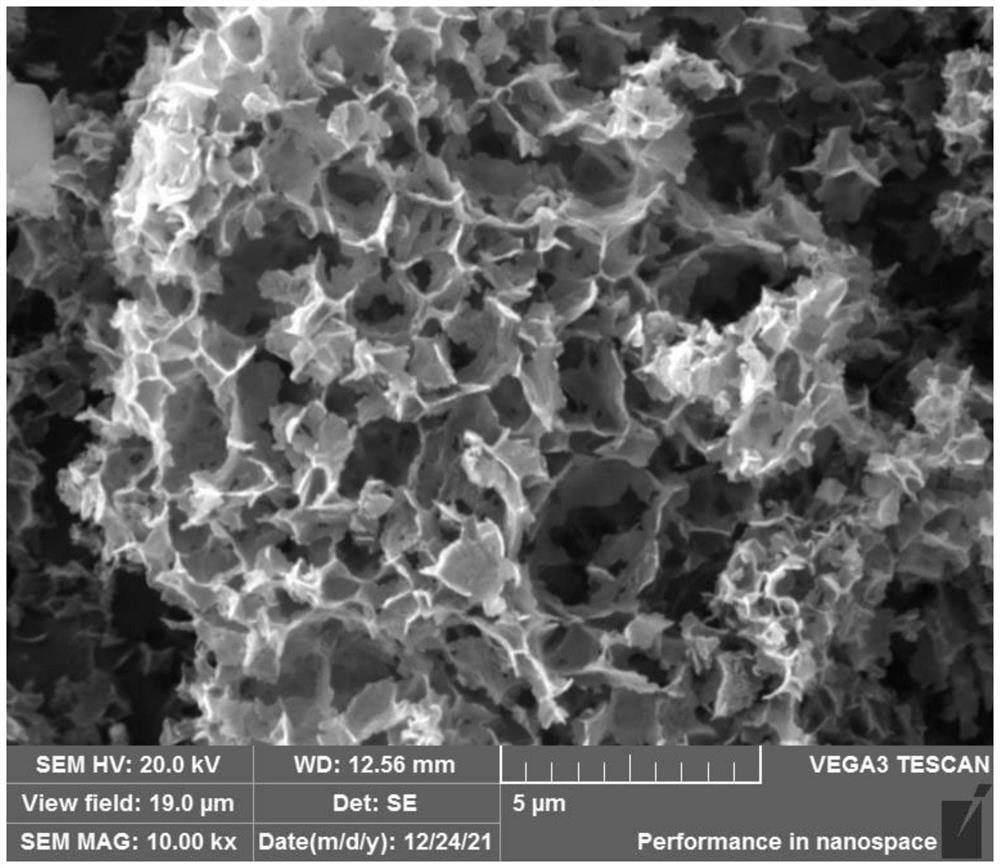

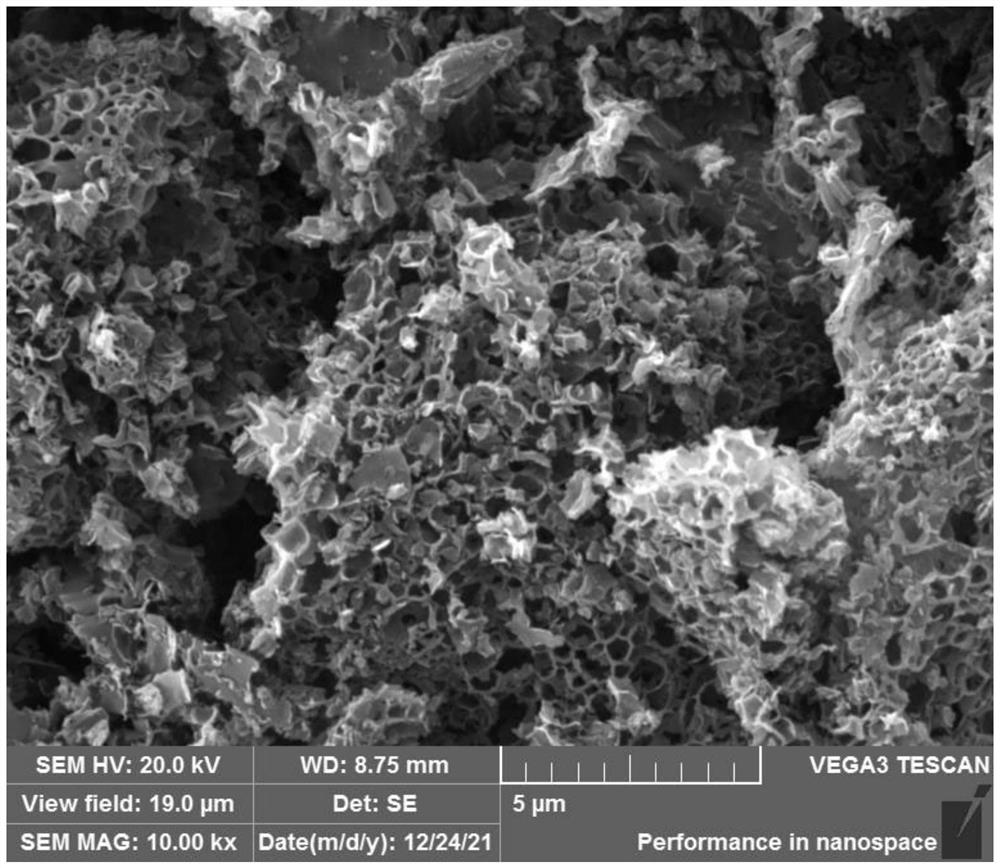

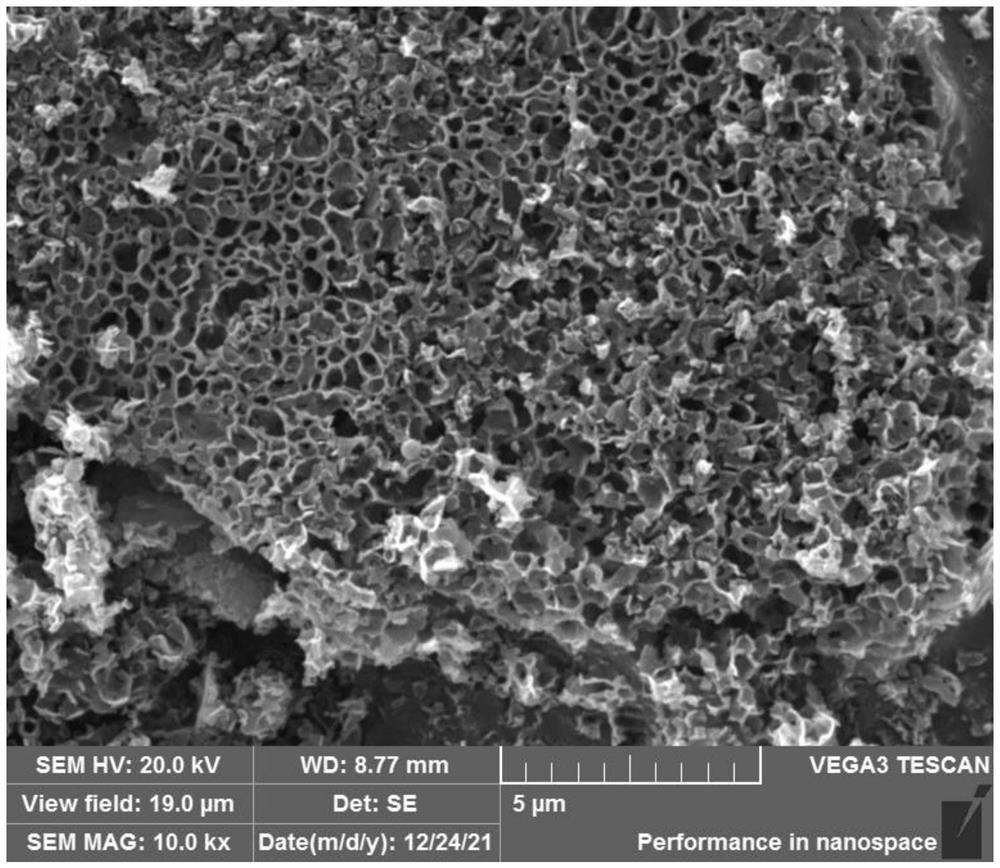

[0072] from image 3 The scanning electron microsco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com