Ultrasonic cleaning device and method for outer surface of zirconium alloy pipe

A technology of ultrasonic cleaning and zirconium alloy, which is applied in the direction of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., and can solve the problems of ineffective removal of sticky dirt on the surface of pipes and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

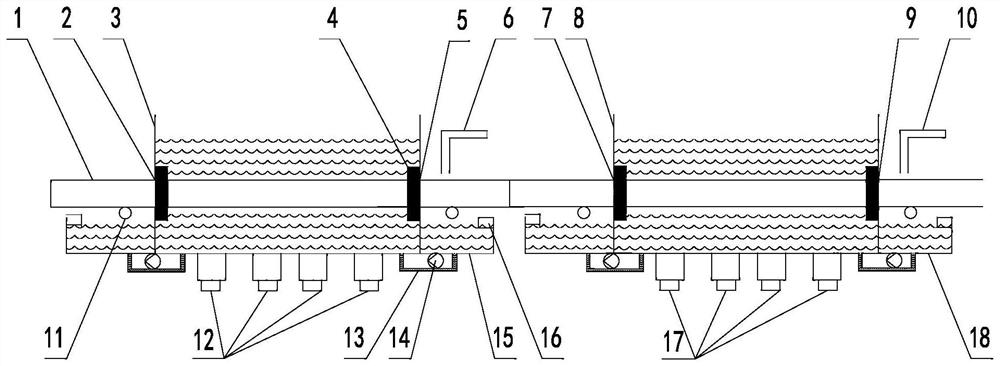

[0028] The present invention provides an ultrasonic cleaning device for the outer surface of a zirconium alloy pipe 1, such as figure 1 As shown, it includes: a first cleaning tank 3, a second cleaning tank 8, a cleaning agent recovery tank 15 and a first return water system, wherein the first cleaning tank 3 contains cleaning agents, and the bottom of the first cleaning tank 3 is provided with The first ultrasonic generator 12, preferably, the first ultrasonic generator 12 is movably connected with the first cleaning tank 3; the second cleaning tank 8 contains deionized water, and the bottom of the second cleaning tank 8 is provided with a second ultrasonic generator 17. Preferably, the second ultrasonic generator 17 is movably connected to the second cleaning tank 8. In a specific embodiment, the oscillator frequencies of the first ultrasonic generator 12 and the second ultrasonic generator 17 are 28KHz˜40KHz.

[0029] The cleaning agent recovery tank 15 is disposed between...

Embodiment 2

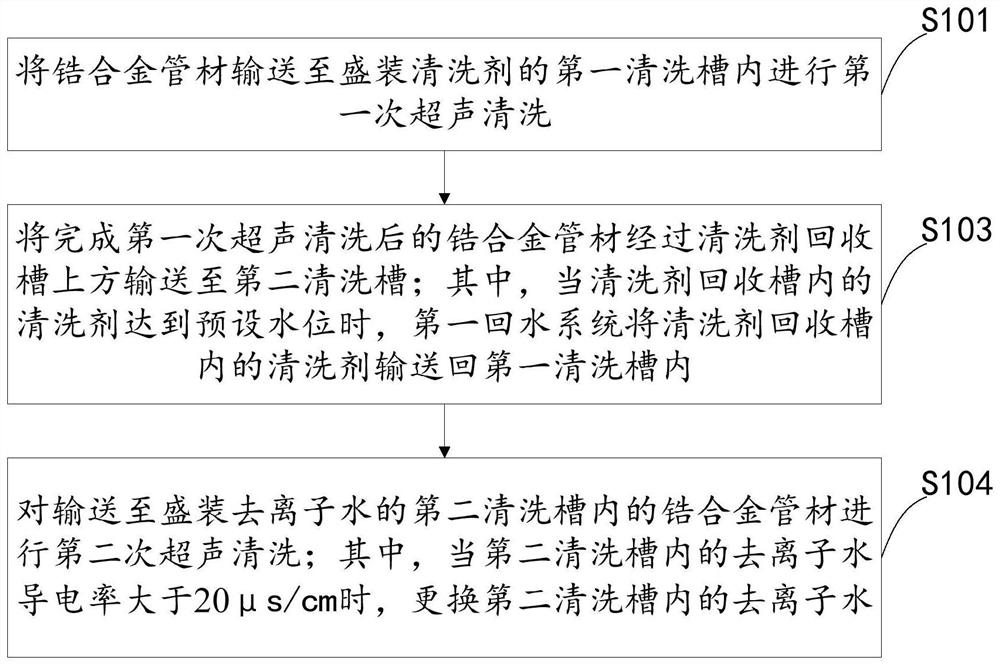

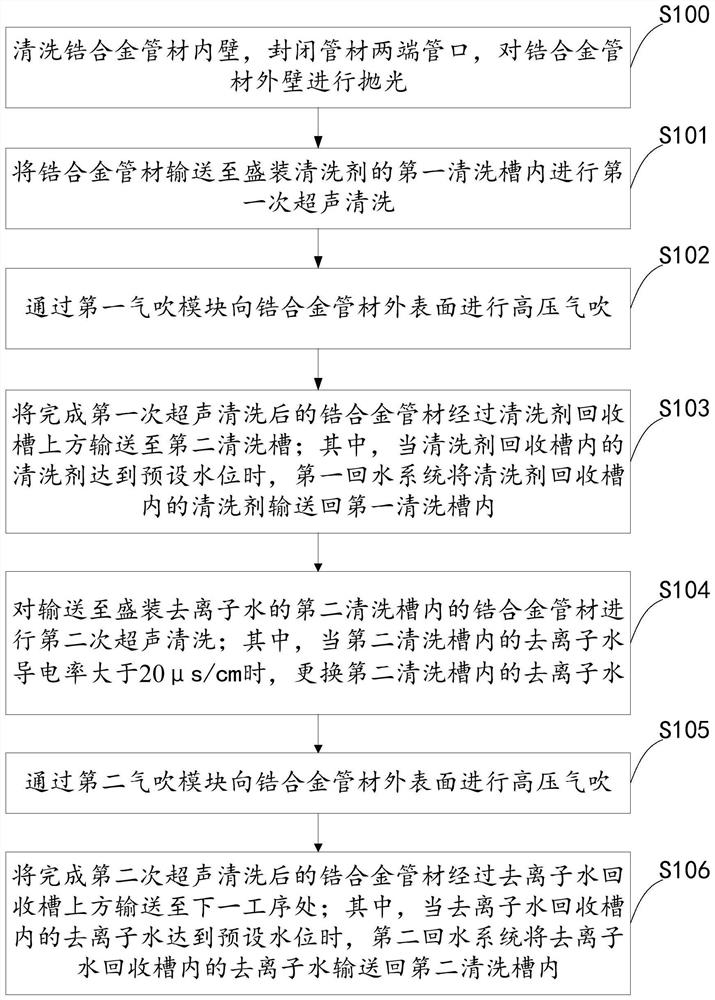

[0042] The invention also provides an ultrasonic cleaning method for the outer surface of the zirconium alloy pipe, such as Figure 2-3 shown, including the following steps:

[0043] In step S101, the zirconium alloy pipe is transported to a first cleaning tank containing a cleaning agent for the first ultrasonic cleaning.

[0044] Specifically, in this solution, the first cleaning tank is provided with a first ultrasonic generator for generating ultrasonic waves. Preferably, the vibration frequency of the first ultrasonic generator is set to 28KHz˜40KHz. The first cleaning tank is filled with a cleaning agent with a concentration of 1% to 5%. The cleaning agent is preferably Alconox powdered precision cleaning agent, which is used to clean the outer surface of the zirconium alloy pipe to be cleaned, and is mainly used to clean the residual adhesion dirt on the surface of the pipe. . In a specific embodiment, the zirconium alloy pipe can be controlled by the conveying system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com