Chip-on-board packaging method and chip-on-board packaging system

A chip packaging and chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of COB packaging requiring manual participation and low production efficiency, and achieve the effect of solving low production efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

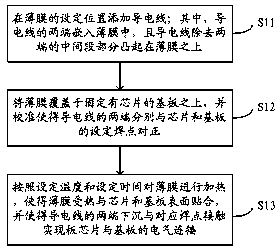

[0024] Such as figure 1 As shown, the chip-on-board packaging method proposed in this application includes the following steps:

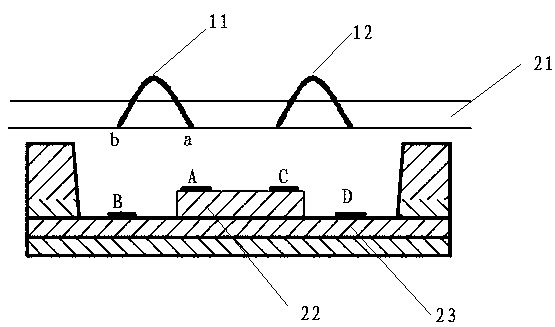

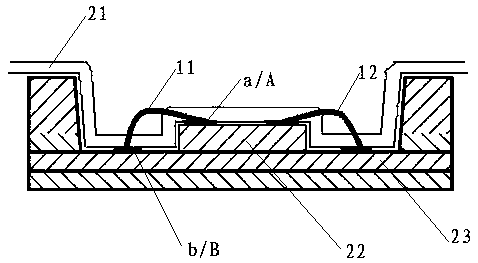

[0025] Step S11: adding conductive wires at the set position of the film; wherein, both ends of the conductive wires are embedded in the film, and the middle section of the conductive wires except the two ends protrudes above the film.

[0026] Fluorine resin is used as the material to make a film with a thickness of about 50 to 600 microns. In terms of film thickness control, if it is too thin, the oxidation resistance will be poor and the requirements for the process will be high. If it is too thick, the chip volume will be affected. The optimal thickness Controlled at 80 to 300 microns.

[0027] In the film-making process, it is necessary to add conductive wires at the set position. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com