Method and device for controlling welding of mask ear loops, storage medium and processor

A technology of ear loops and masks, which is applied in the field of controlling the welding of mask ear loops, can solve the problems of low production efficiency of masks, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to an embodiment of the present invention, an embodiment of a method for controlling the welding of mask ear loops is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions , and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

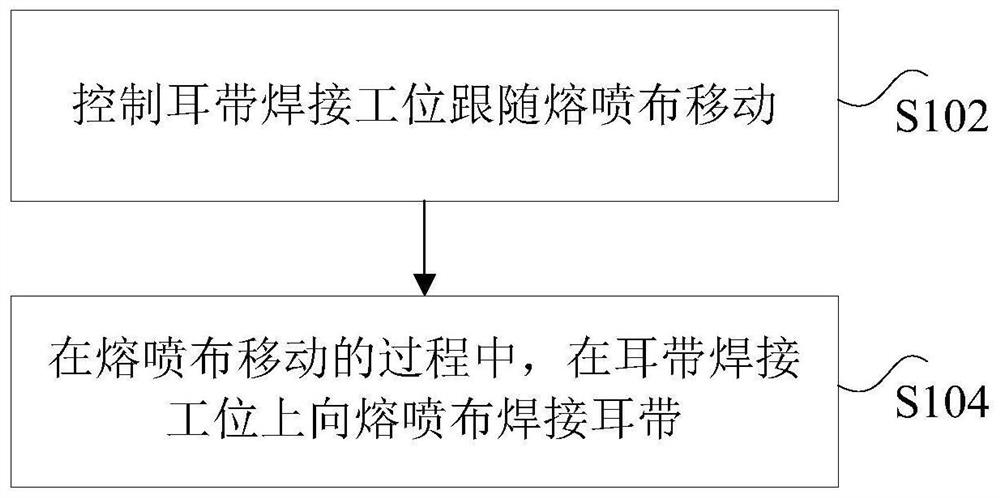

[0031] figure 1 It is a flow chart of a method for controlling the welding of mask ear loops according to an embodiment of the present invention. like figure 1 As shown, the method may include the following steps:

[0032] Step S102, controlling the earband welding station to move along with the melt-blown cloth.

[0033] In the technical solution provided by the above step S102 of the present invention, the moving speed of the earband welding station and the moving speed of the melt...

Embodiment 2

[0054] According to an embodiment of the present invention, a device for controlling the welding of ear loops of a mask is also provided.

[0055] figure 2 It is a schematic diagram of a device for controlling the welding of mask ear loops according to an embodiment of the present invention. like figure 2 As shown, the device 20 for controlling the welding of mask ear straps may include: melt blown cloth 21; ear strap welding station 22, which is used to follow the melt blown cloth and weld the ear straps to the melt blown cloth.

[0056] In this embodiment, the moving speed of the earband welding station 22 and the moving speed of the meltblown cloth 21 can be kept consistent, so that during the moving process of the meltblown cloth 21, the earband welding station 22 can spray Cloth 21 welds the ear straps, so that the time for welding the ear straps can be reduced and the efficiency of welding the ear straps can be improved.

[0057] As an optional embodiment, the devic...

Embodiment 3

[0075] The technical solutions of the embodiments of the present invention are illustrated below in combination with preferred implementation modes.

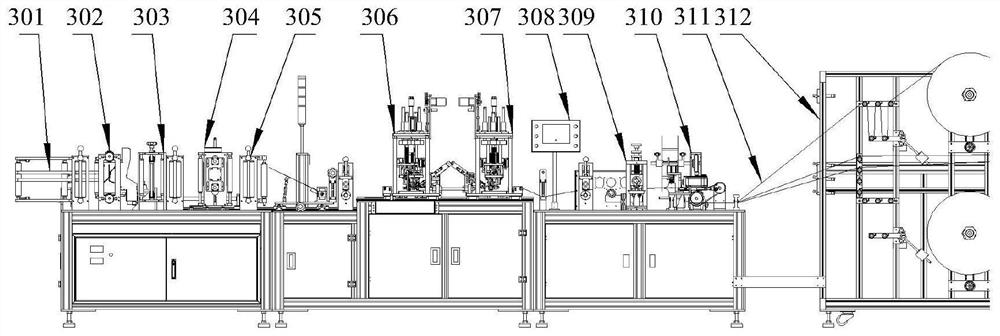

[0076] image 3 It is a structural diagram of a mask machine from a first perspective according to an embodiment of the present invention. like image 3 As shown, the mask machine can include: mask finished off-line station 301, mask finished product cutting station 302, pre-cutting shaping station 303, follow-up welding and folding station 304, folding forming station 305, first Follow-up welding earband station 306, second follow-up earband welding station 307, operating table 308, welding station 309, upper nose bridge station 310, melt-blown cloth 311, melt-blown cloth feeding frame 312.

[0077] Figure 4 It is a structural diagram of a second viewing angle of a mask machine according to an embodiment of the present invention. Figure 4 As shown, the mask machine can also include: ear strap welding station guide rail 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com