Automatic battery side plate installation machine

An automatic installation and battery-side technology, which is applied in the direction of battery assembly, secondary battery manufacturing, climate sustainability, etc., can solve the problems of low battery production efficiency, achieve the effect of solving low production efficiency and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described herein are merely used to explain the present invention and are not intended to qualify the present invention.

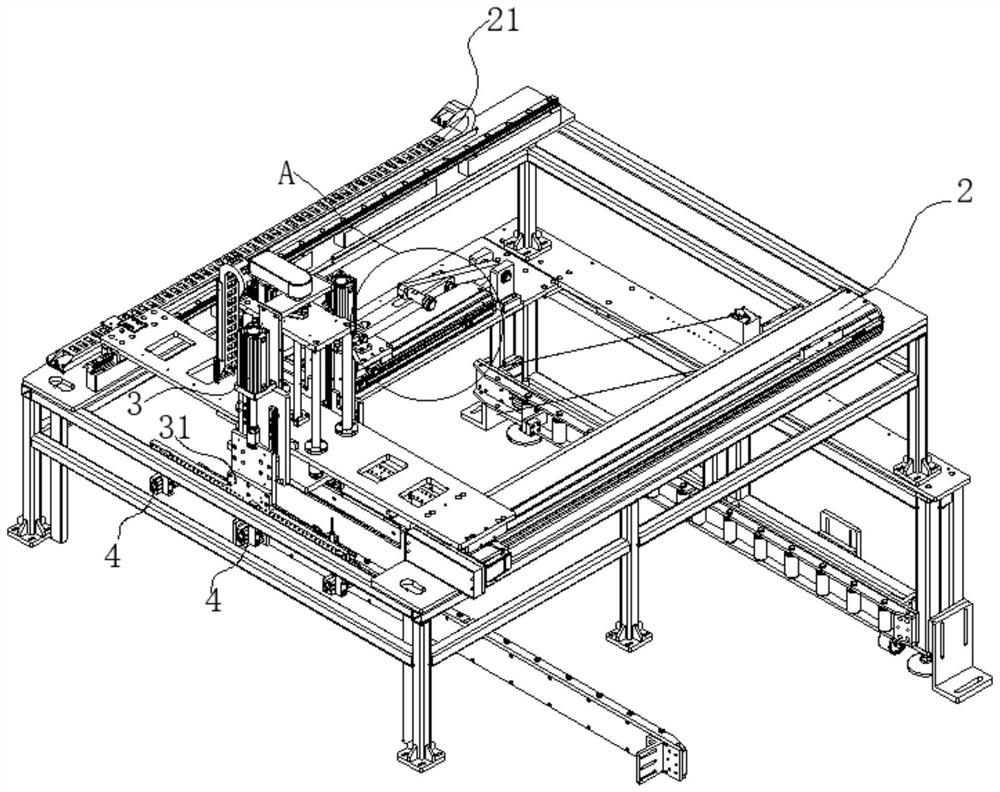

[0023] The following is combined with the attached Figure 1-4 Further detailed description of the present invention.

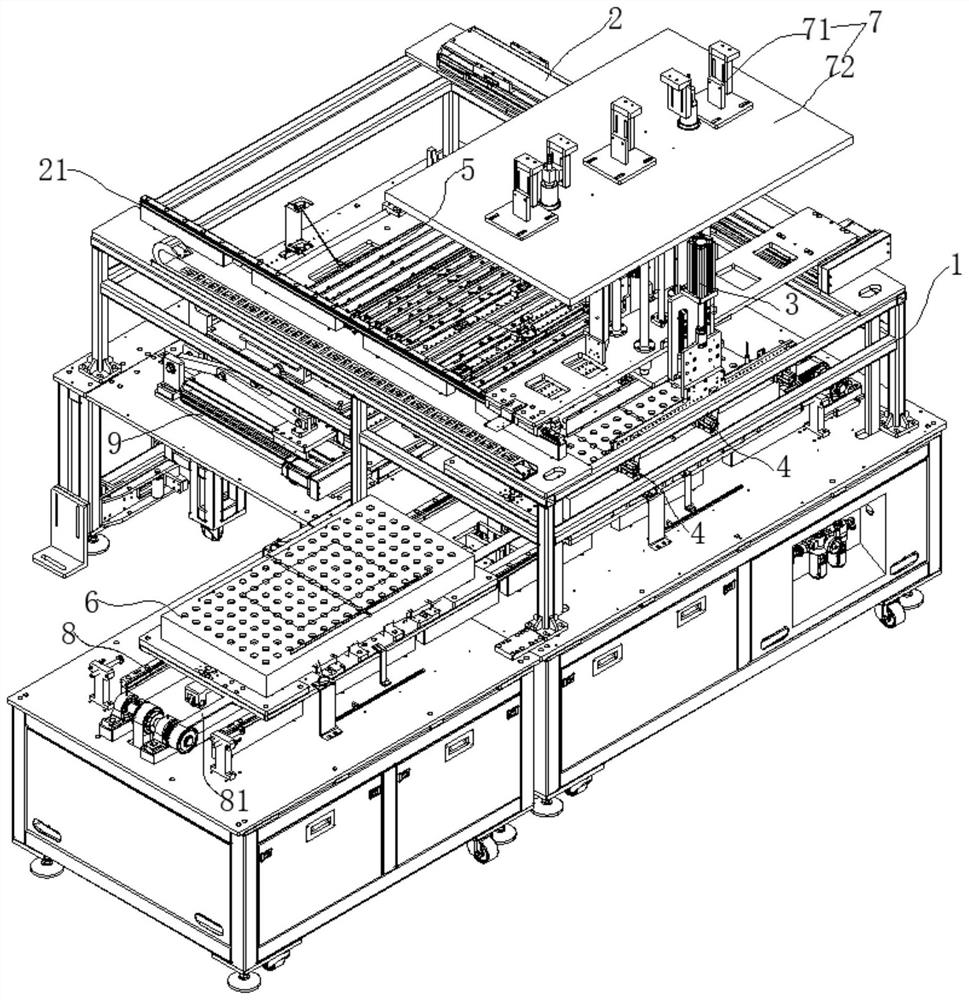

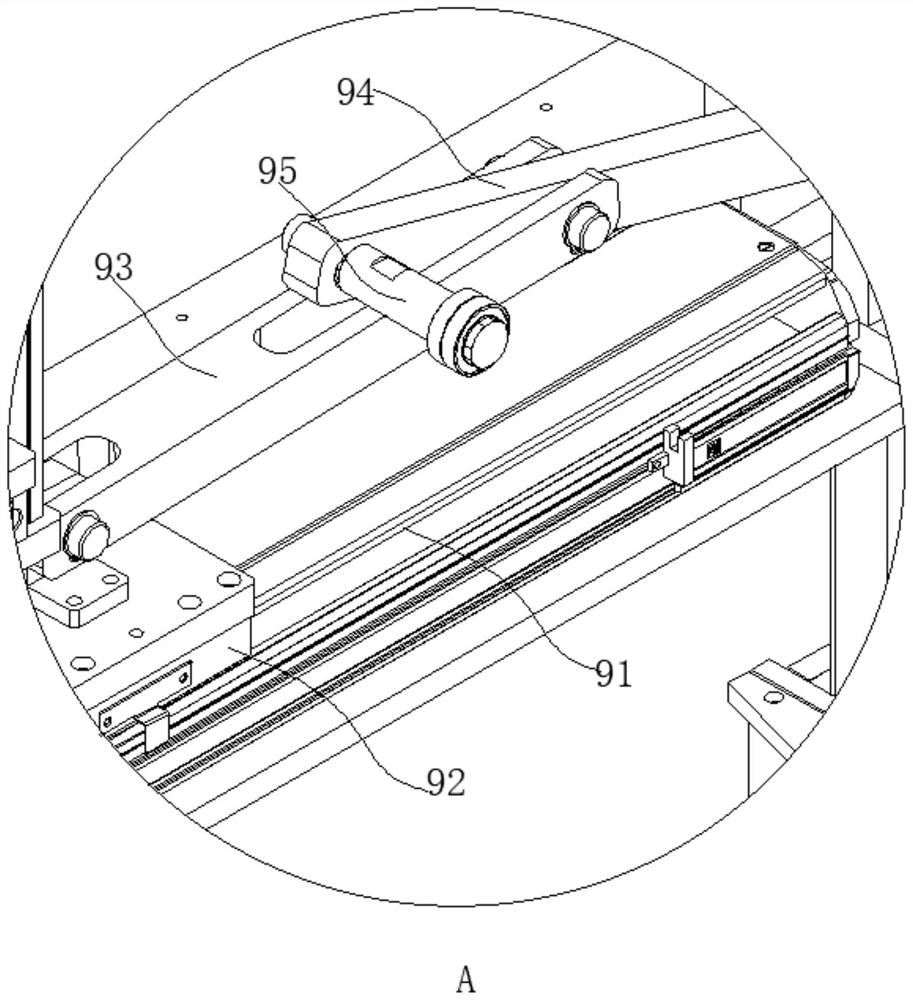

[0024] A kind of automatic installation battery side plate machine, combined Figure 1-Figure 4 , including: bracket 1, transplanting mechanism, side plate clamping table 4, side plate storage tooling 5, module tooling table and positioning device; transplanting mechanism is set on bracket 1, side plate clamp claw 4 is set at the output end of the transplanting mechanism, side plate clamp claw 4 is used to clamp the side plate, side plate storage tooling 5 and module tooling table are located under the transplanting mechanism, transplanting mechanism is used to drive the side plate clamp claw towards the side plate storage tooling or module tooling table movement; side plate storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com