Preparation method and application of acellular porcine dermal matrix antibacterial conductive skin scaffold

A technology of decellularized porcine dermis and decellularized dermis, which is applied in the fields of medical science and prostheses, can solve the problems of poor antibacterial effect and low biocompatibility, so as to promote the regeneration of cells and blood vessels, promote cell growth, The effect of accelerating angiogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

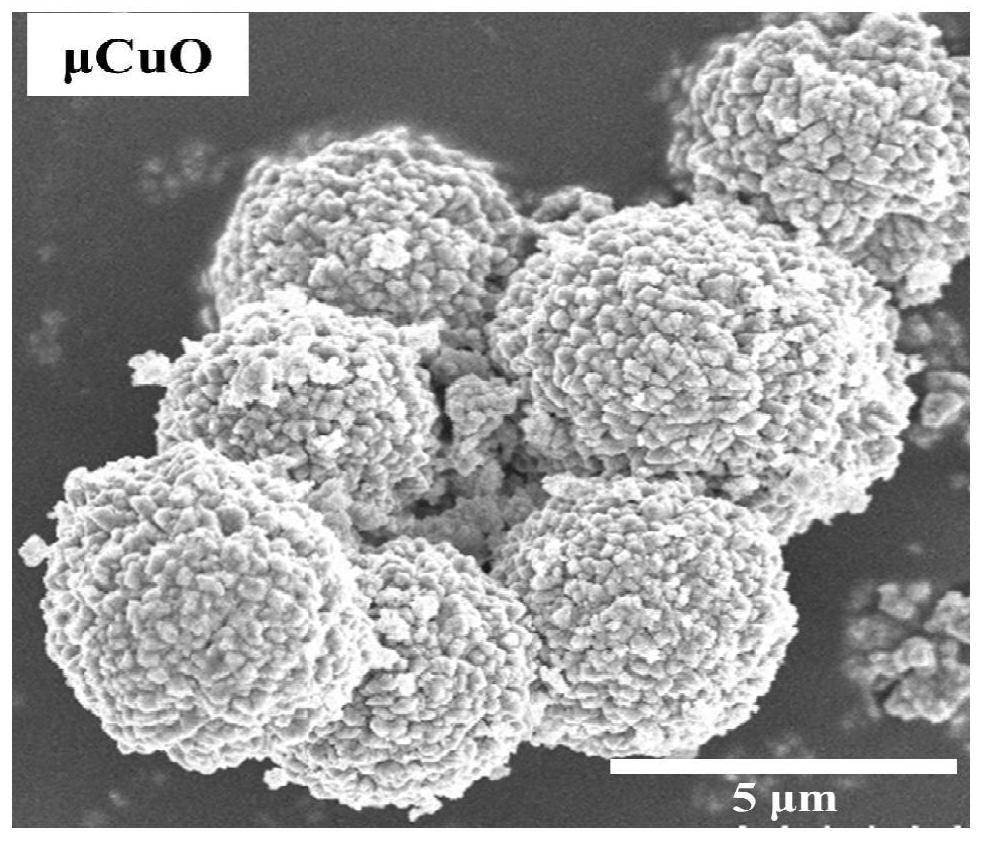

[0048] 1) Preparation of micron-sized porous copper oxide microspheres: Accurately weigh 2.5 g of copper nitrate hydrate Cu(NO 3 ) 2 ·3H 2 O was mixed with 20 mL of ethanol, 20 mL of ammonium hydroxide aqueous solution and 10 mL of aqueous sodium hydroxide solution, and the mixture was transferred to a hydrothermal reactor and heated at 140 °C for 14 hours. The precipitate was collected by centrifugation and washed alternately with deionized water and absolute ethanol. Three times, dried in an oven at 50 °C for 8 h to obtain micron-sized porous copper oxide microspheres.

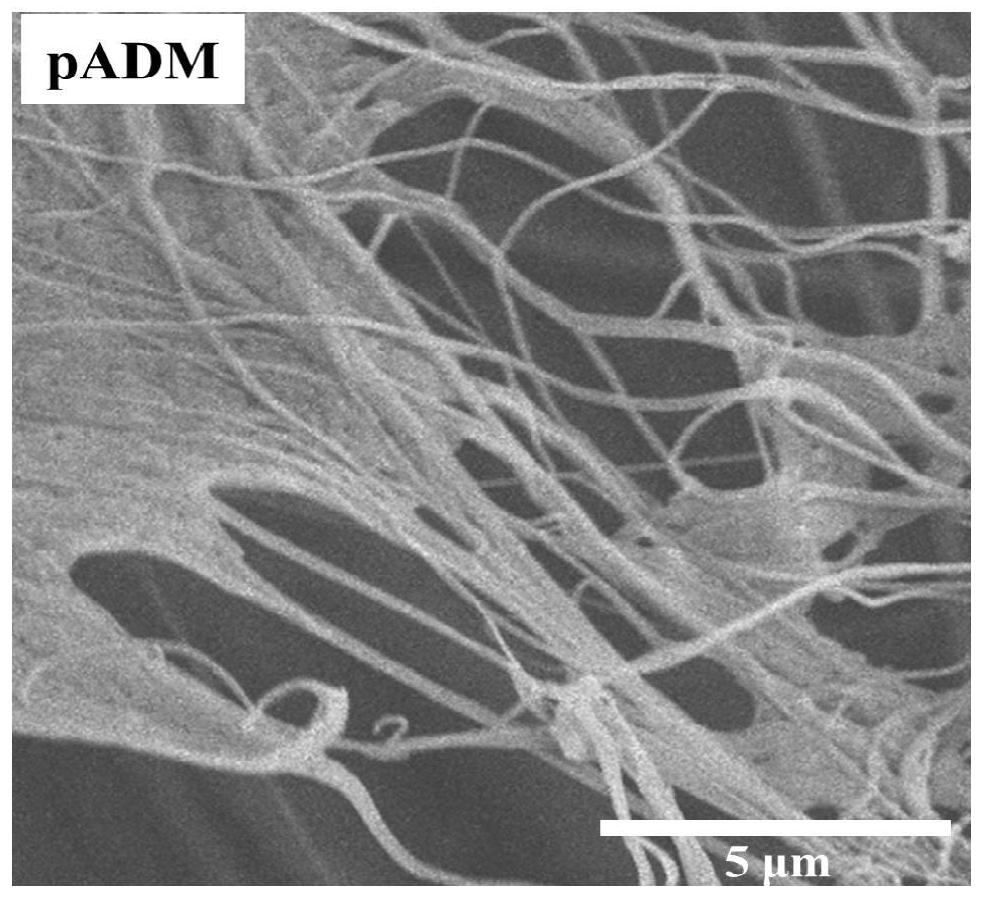

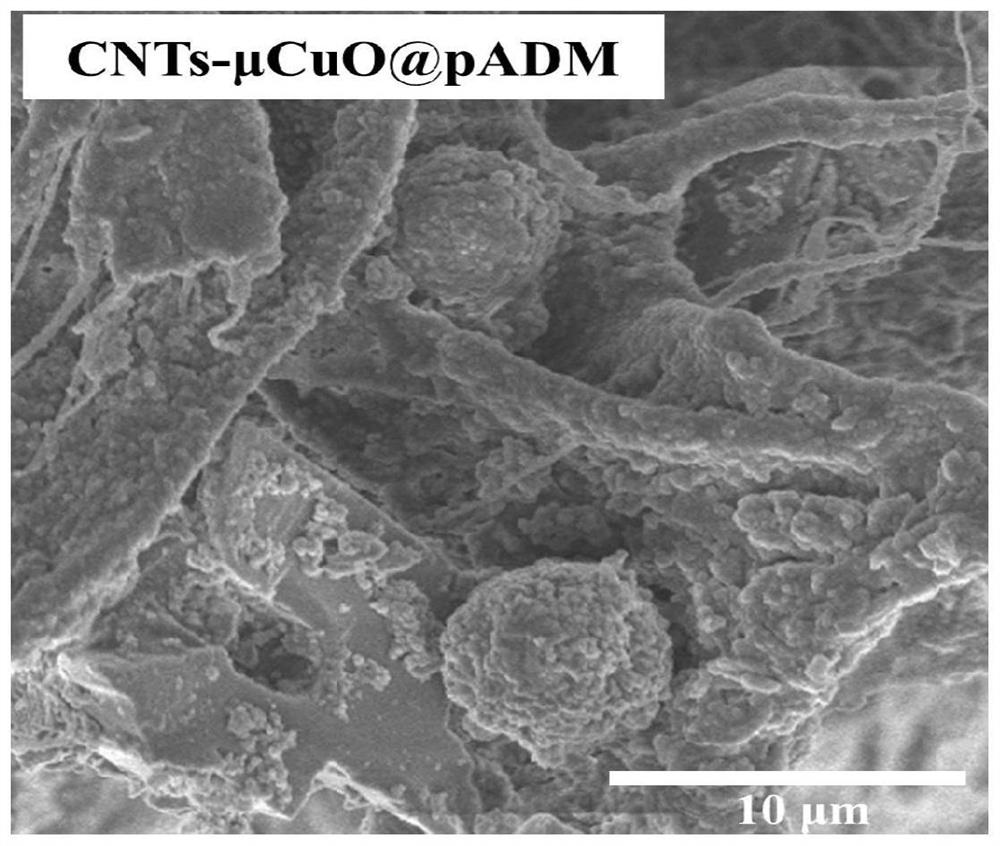

[0049] 2) Preparation of pH-controlled release acellular porcine dermal matrix antibacterial conductive skin scaffold: Take 0.5 mL of multi-walled carbon nanotube aqueous solution and 0.05 mL of micron-sized porous copper oxide microsphere aqueous solution in 5.0 mL of deionized water for 10 minutes ultrasonic treatment, cut The porcine acellular dermal matrix with a diameter of 3.0 cm was immersed in the ...

Embodiment 2

[0051] 1) Preparation of micron-sized porous copper oxide microspheres: Accurately weigh 3.0 g of copper nitrate hydrate Cu(NO 3 ) 2 ·3H 2 O was mixed with 30 mL of ethanol, 30 mL of ammonium hydroxide aqueous solution and 20 mL of sodium hydroxide, and the mixture was transferred to a hydrothermal reactor and heated at 120 °C for 12 hours. The precipitate was collected by centrifugation and washed three times alternately with deionized water and absolute ethanol. , and dried in an oven at 50 °C for 8 h to obtain micron-sized porous copper oxide microspheres.

[0052] 2) Preparation of pH-controlled release decellularized porcine dermal matrix antibacterial conductive skin scaffold: Take 0.1 mL of multi-walled carbon nanotubes aqueous solution and 0.1 mL of micron-sized porous copper oxide microsphere aqueous solution in 7.5 mL of deionized water for 20 minutes of ultrasonic treatment, cut out The pADM with a diameter of 3.0 cm was immersed in the mixed solution and continuo...

Embodiment 3

[0054] 1) Preparation of micron-sized porous copper oxide microspheres: Accurately weigh 5.0 g of copper nitrate hydrate Cu(NO 3 ) 2 ·3H 2 O was mixed with 40 mL of ethanol, 40 mL of ammonium hydroxide aqueous solution and 30 mL of sodium hydroxide, and the mixture was transferred to a hydrothermal reactor and heated at 100 °C for 6 hours. The precipitate was collected by centrifugation and washed three times alternately with deionized water and absolute ethanol. , and dried in an oven at 50 °C for 6 h to obtain micron-sized porous copper oxide microspheres.

[0055] 2) Preparation of pH-controlled release acellular porcine dermal matrix antibacterial conductive skin scaffold: Take 2.0 mL of multi-walled carbon nanotubes aqueous solution and 0.2 mL of micron-sized porous copper oxide microspheres aqueous solution in 10.0 mL of deionized water for 10 minutes ultrasonic treatment, cut out The pADM with a diameter of 3.0 cm was immersed in the mixed solution and continuously sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com