Modified Y molecular sieve and preparation method thereof

A molecular sieve and modification technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of increasing the yield of light hydrocarbon components, accelerating carbon deposition in pores, catalyst deactivation, mesoporous content problems such as insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 10.0g of raw material Y-1 molecular sieve was added to the vacuum reaction kettle, and the pressure in the kettle was reduced to 0.1 atm and maintained at 50°C; 100g of aqueous solutions of 0.05mol / L methylamine and 0.10mol / L ammonia were prepared, Under the condition that the vacuum degree is kept at 0.1 atmosphere, the aqueous solution is added into the reaction kettle. After the addition is completed, the stirring is continued for 10 minutes, and then air is introduced to restore the normal pressure state. Then, it was stirred at 60° C. for 10 minutes, filtered, dried, and calcined to obtain a modified Y molecular sieve without metal ions, numbered MY-1.

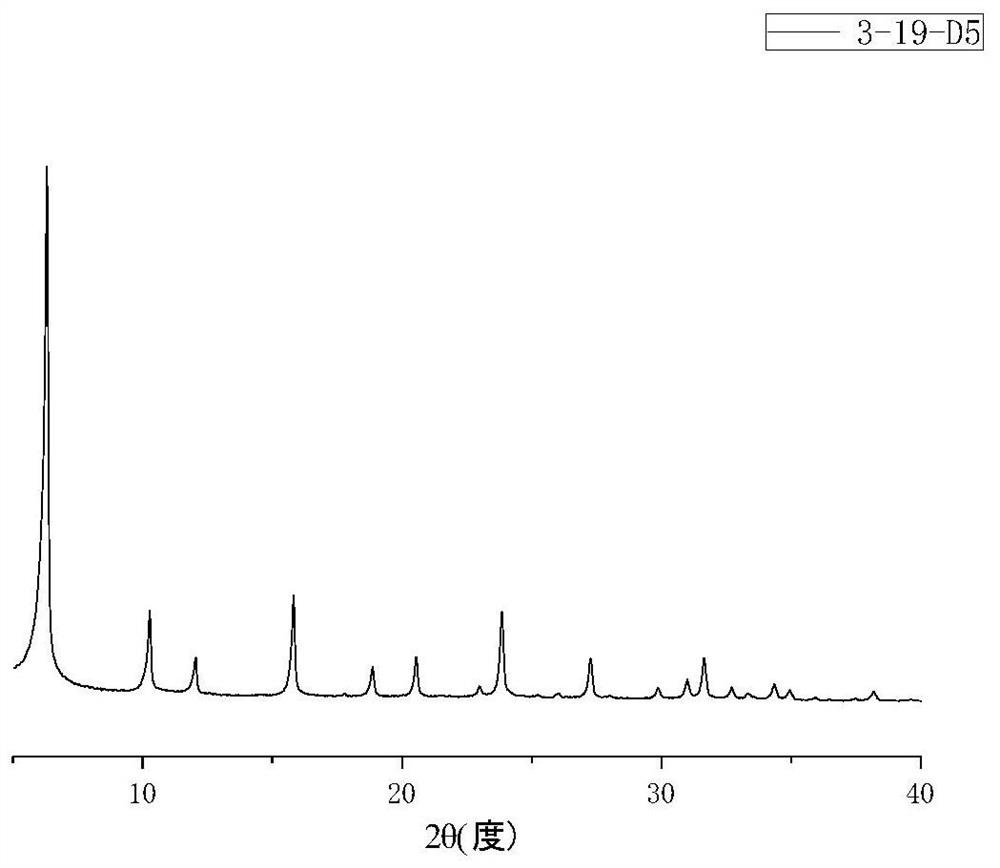

[0061] The specific properties of Y-1 and MY-1 are shown in Table 1 and Figure 1A and Figure 1B shown. Depend on Figure 1A and Figure 1B The comparison shows that the position of each diffraction peak in the XRD spectrum after modification is almost unchanged, the degree of reduction of the diffraction peak i...

Embodiment 2

[0063] 20.0g of raw material Y-2 molecular sieve was added to the vacuum reaction kettle, and the pressure in the kettle was reduced to 0.09 atmosphere at 400°C and maintained; 100g of aqueous solutions of 0.8mol / L ethylamine and 0.50mol / L ammonia were prepared, Under the condition that the vacuum degree is kept at 0.1 atmosphere, the aqueous solution is added into the reaction kettle. After the addition is completed, the stirring is continued for 10 minutes, and then air is introduced to restore the normal pressure state. Stir at 80° C. for 5 hours, filter, dry, and calcine to obtain a modified Y molecular sieve without metal ions, numbered MY-2.

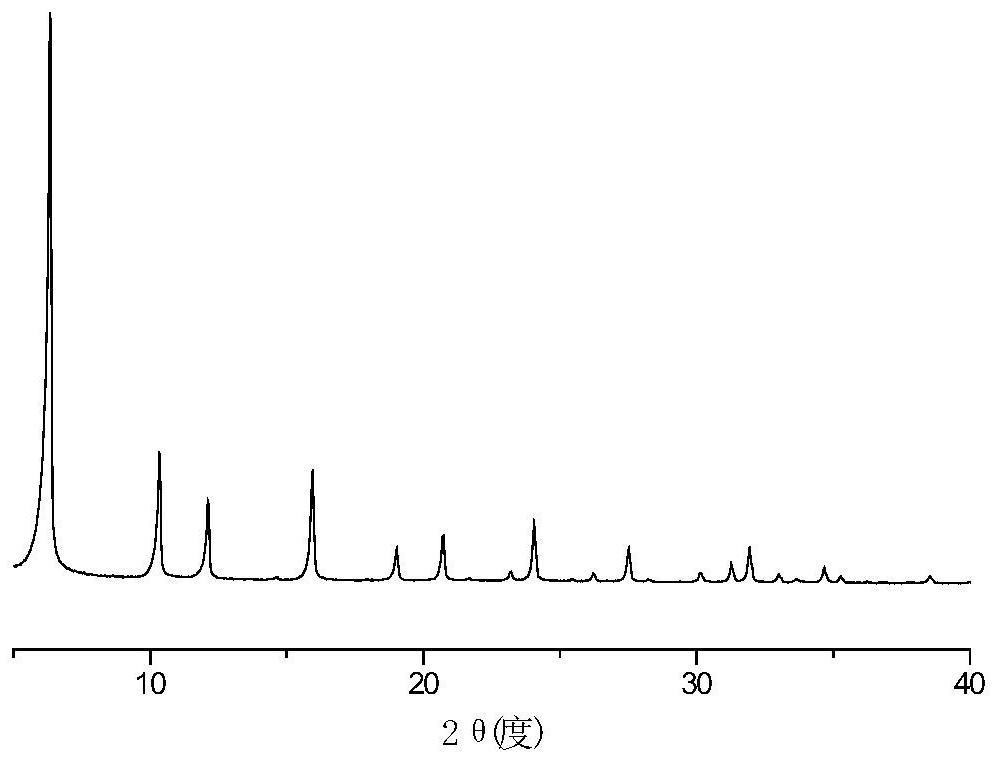

[0064] The specific properties of Y-2 and MY-2 are shown in Table 1 and Figure 2A and Figure 2B shown. Depend on Figure 2A and Figure 2B The comparison shows that the position of each diffraction peak in the XRD spectrum after modification is almost unchanged, the degree of reduction of the diffraction peak is low, and the ...

Embodiment 3

[0066] Add 8.0 g of raw material Y-3 molecular sieve into the vacuum reaction kettle, and at 200 ° C, reduce the pressure in the kettle to 0.09 atmospheric pressure and keep it; prepare 100 g of an aqueous solution of 0.5 mol / L ethylenediamine and 0.15 mol / L ammonia, Under the condition of keeping the vacuum degree at 0.09 atmospheres, the aqueous solution was added into the reaction kettle. After the addition was completed, stirring was continued for 5 minutes, and then air was introduced to restore the normal pressure state. Stirring at 40° C. for 50 minutes, filtering, drying, and calcining to obtain a modified Y molecular sieve without metal ions, numbered MY-3.

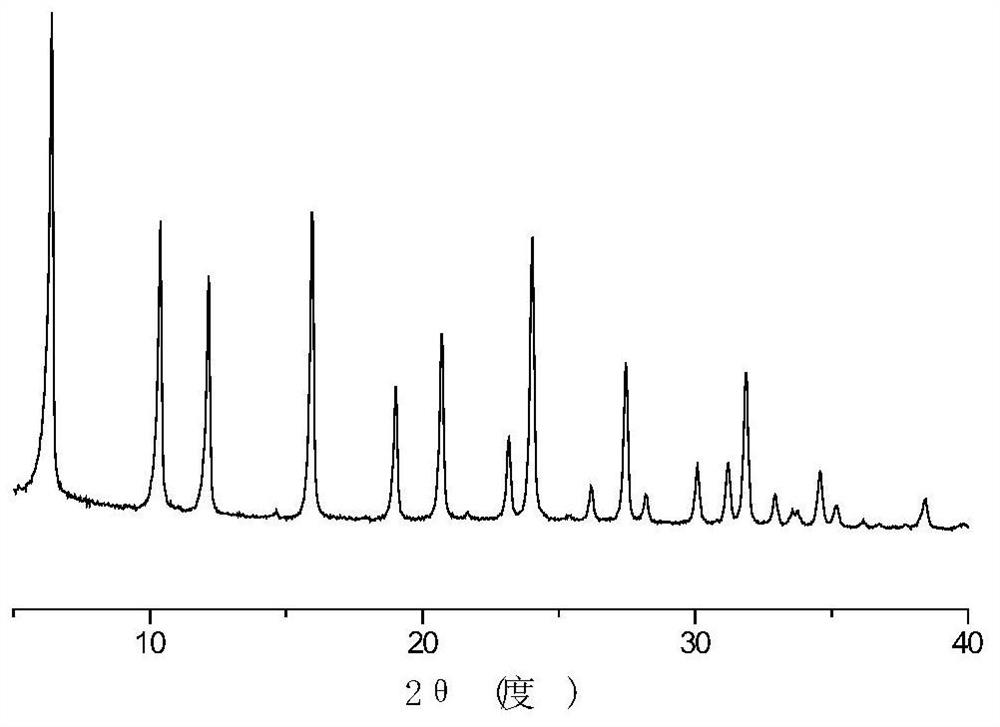

[0067] The specific properties of Y-3 and MY-3 are shown in Table 1 and Figure 3A and Figure 3B shown. Depend on Figure 3A and Figure 3B The comparison shows that the position of each diffraction peak in the XRD spectrum after modification is almost unchanged, the degree of reduction of the diffraction peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com