Hydrogen-rich tea and preparation method thereof

A technology of hydrogen-rich tea and tea, which is applied in the field of hydrogen-rich tea and its preparation, can solve the problems of limited use of hydrogen-rich water sticks such as the shape and size of tea sets, affecting the taste of drinking water, and being easily contaminated with other germs. Prevents cell canceration and has a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

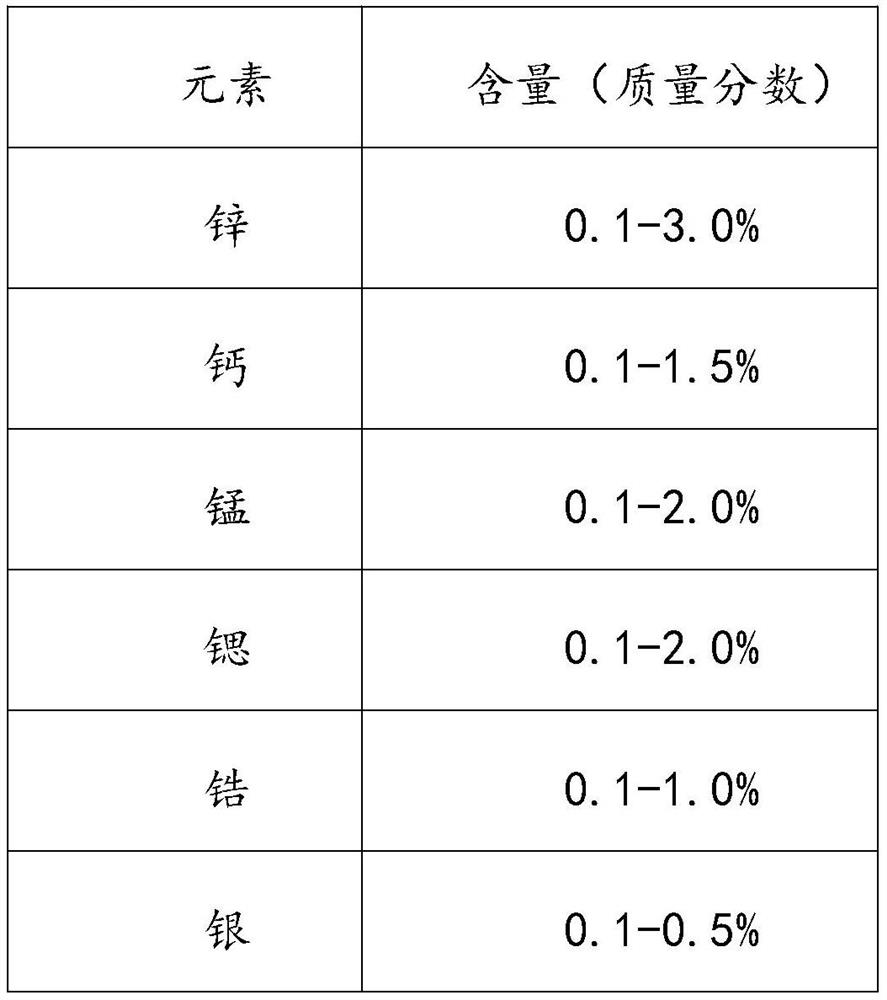

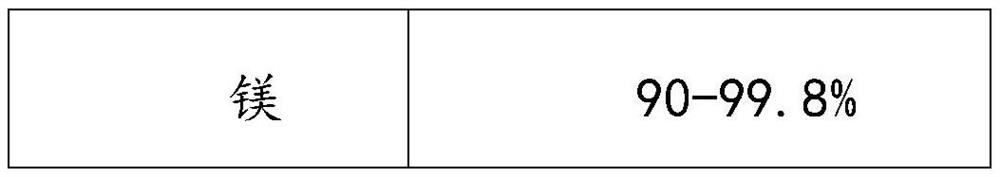

[0026] This embodiment provides a combination of granular tea (such as buckwheat tea) and magnesium alloy particles in bulk tea, the particle size is 1-3 mm in diameter, and the volume ratio of tea and magnesium alloy particles is 1-2:1.

[0027] The preparation method of the magnesium alloy particles: preparing, smelting and casting according to the composition ratio to obtain a magnesium alloy ingot of the required composition, then grinding the surface of the magnesium alloy ingot clean, and irradiating the surface of the magnesium alloy by laser under the protection of argon gas. The magnesium alloy ingot is heated into a molten liquid, poured onto a copper roll with a rotating speed of 35-50m / s and rapidly cooled to obtain magnesium alloy strips, and then crushed by ball milling for 2-8 hours to obtain magnesium alloy particles.

Embodiment 2

[0029] This embodiment provides a sheet-like tea, magnesium alloy sheet (non-porous / porous) combined bulk tea, specifically including flat, sheet, tongue and other shapes of tea (Xihu Longjing, Mengding Huangya, Houkui, Souchong, etc.) Black tea, etc.), magnesium alloy sheets are divided into two types: non-porous and porous (1 / 2 of the circumference is evenly distributed), and the volume ratio of tea leaves and magnesium alloy sheets is 1-2:1.

[0030] The preparation method of the magnesium alloy sheet is as follows: material preparation, smelting and casting are carried out according to the composition ratio to obtain a magnesium alloy ingot with the required composition. Then, the magnesium alloy flakes are obtained by vibration cutting, which is mechanically cut / cut into the required size of the magnesium alloy flakes; the porous flakes are punched with holes of the corresponding size on the magnesium alloy flakes.

Embodiment 3

[0032] This embodiment provides a combination of curly tea leaves and magnesium alloy wire balls in bulk tea, specifically including curly, spiral, and bead-shaped tea leaves (Rizhao Green Tea, Biluochun, Yongxi Huoqing, etc.), and the magnesium alloy wire balls are made of magnesium alloy The hollow silk balls with a diameter of 2-10mm are wound with silk, and the volume ratio of tea leaves to magnesium alloy silk balls is (1-2):1.

[0033] The preparation method of the magnesium alloy wire ball: preparing, smelting and casting according to the composition ratio to obtain a magnesium alloy ingot of the required composition, and then continuously and slowly drawing through multiple passes with a small deformation amount to obtain a diameter of 0.1-0.5mm and a length of 0.1-0.5mm. Magnesium alloy filaments of 10-50mm are manually wound to obtain magnesium alloy wire balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com