Preparation method and application of high-activity stable anode material

A stable anode and high-activity technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of lack of reliable solutions and achieve good reusability and efficient generation The effect of enhanced capacity and wide electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

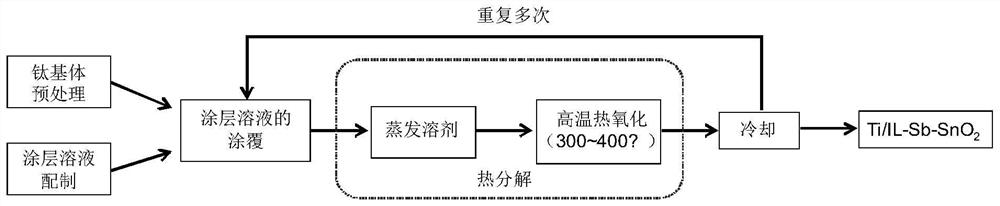

[0042] A preparation method of a highly active and stable anode material of the present invention, refer to figure 1 , the method includes the following steps:

[0043] 1) Anode titanium substrate pretreatment: the titanium substrate is subjected to a series of pretreatments such as grinding, organic solvent cleaning, degreasing, and etching treatment;

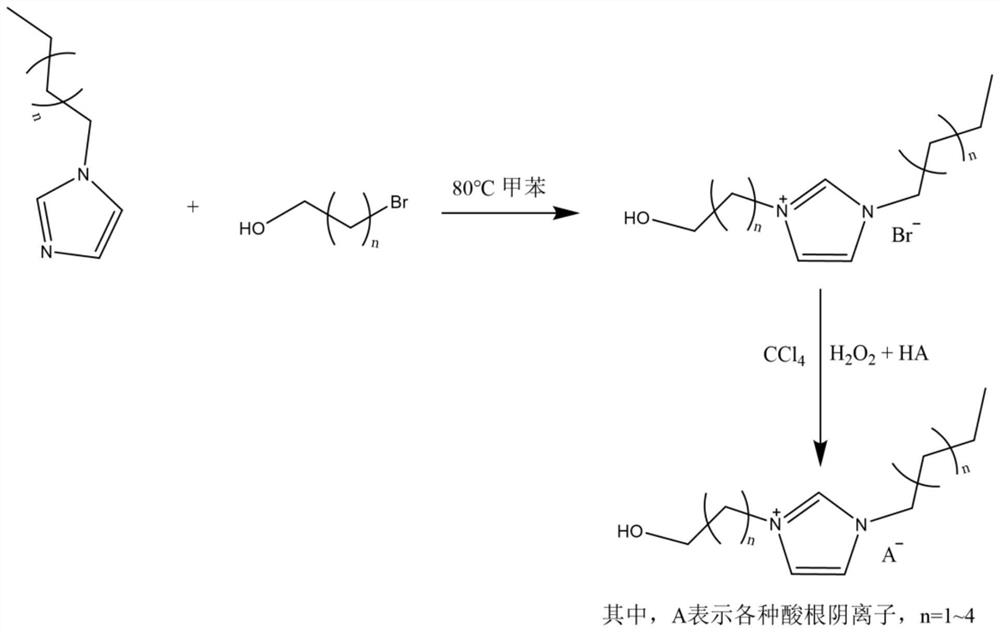

[0044] 2) Preparation of coating solution: the coating solution includes Sb ion, Sn ion and hydroxyimidazole ionic liquid, and the specific method is:

[0045] 2-1) SnCl 4 ·5H 2 O and Sb 2 O 3 Completely dissolve with a small amount of hydrochloric acid, and then prepare an anhydrous ethanol coating solution with a Sn ion concentration of 1.0 to 1.5 mol / L and a molar ratio of Sn:Sb=100:10 to 100:5;

[0046] 2-2) Add an appropriate amount of polyethylene glycol to the anhydrous ethanol coating solution and mix evenly, then add hydroxyimidazole ionic liquid, and mix evenly to obtain a coating solution. The content of the hy...

Embodiment 1

[0057] A method for preparing a highly active and stable anode material, comprising the following steps:

[0058] 1) Anode titanium substrate pretreatment: the titanium substrate is subjected to a series of pretreatments such as grinding, organic solvent cleaning, degreasing, and etching treatment;

[0059] 2) Prepare the coating solution:

[0060] 2-1) SnCl 4 ·5H 2 O and Sb 2 O 3 Completely dissolve with a small amount of hydrochloric acid, and then prepare an anhydrous ethanol coating solution with a Sn ion concentration of 1.0 mol / L and a molar ratio of Sn:Sb=100:5;

[0061] 2-2) Add an appropriate amount of polyethylene glycol to the anhydrous ethanol coating solution and mix well, and then add 1-butyl-3-ethylhydroxyimidazolium methanesulfonate ionic liquid [OHpbim][CH 3 SO 3 ], and evenly mixed to obtain a coating solution, the content of 1-butyl-3-ethylhydroxyimidazolium methanesulfonate ionic liquid in the coating solution is 40 mg / L.

[0062] 3) Apply the coatin...

Embodiment 2

[0067] A method for preparing a highly active and stable anode material, comprising the following steps:

[0068] 1) Anode titanium substrate pretreatment: the titanium substrate is subjected to a series of pretreatments such as grinding, organic solvent cleaning, degreasing, and etching treatment;

[0069] 2) Prepare the coating solution:

[0070] 2-1) SnCl 4 ·5H 2 O and Sb 2 O 3 Completely dissolve with a small amount of hydrochloric acid, and then prepare an anhydrous ethanol coating solution with a Sn ion concentration of 1.0 mol / L and a molar ratio of Sn:Sb=100:10;

[0071] 2-2) Add an appropriate amount of polyethylene glycol to the anhydrous ethanol coating solution and mix well, and then add 1-butyl-3-ethylhydroxyimidazolium methanesulfonate ionic liquid [OHpbim][CH 3 SO 3], and evenly mixed to obtain a coating solution, the content of 1-butyl-3-ethylhydroxyimidazolium methanesulfonate ionic liquid in the coating solution is 40 mg / L.

[0072] 3) Apply the coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com