High-rigidity PVC electric conduit and preparation method thereof

A high-stiffness, PVC resin technology, applied in the field of high-stiffness PVC power conduits and its preparation, can solve the problems of material toughness decline, plastic hardening, cracking, etc., and achieve the goal of improving mechanical strength, increasing adsorption, and increasing specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

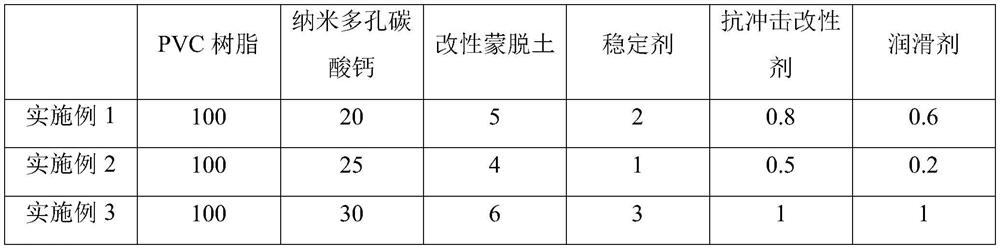

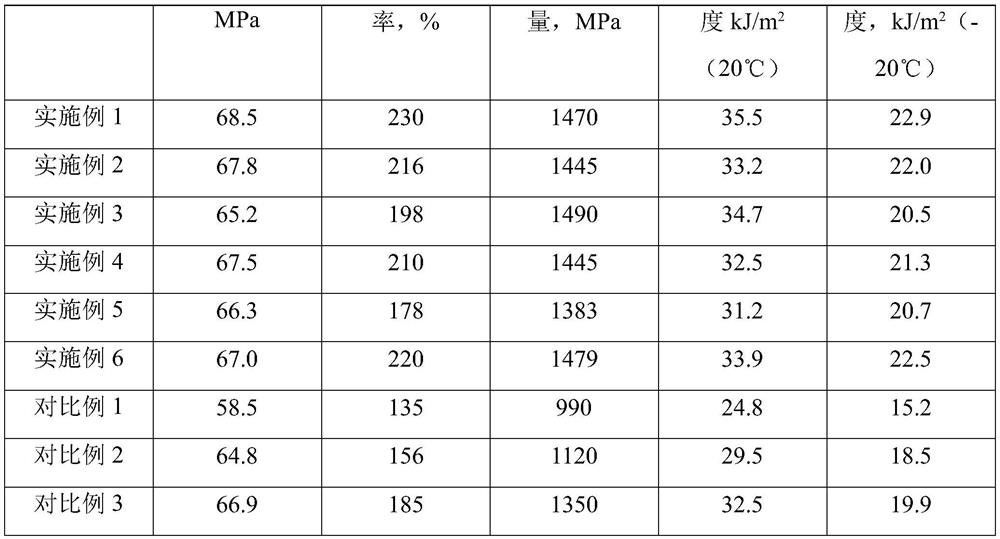

Examples

preparation example 1

[0040] The preparation method of nanoporous calcium carbonate comprises the following steps:

[0041] ① Dissolve 0.3kg of polyvinylpyrrolidone in 5kg of water, add 1.5kg of sodium carbonate, stir evenly to obtain mixed solution A;

[0042] 2. After dissolving 0.8 kg of calcium chloride in 5 kg of water, add 0.1 kg of sodium lauryl sulfate, stir evenly, and adjust the pH to 9 to obtain mixed solution B;

[0043] 3. Add the mixed solution A to the mixed solution B, stir evenly to obtain a suspension; after the suspension is allowed to stand for 8 hours, the filter cake is obtained by suction filtration;

[0044] ④ After washing the filter cake three times with deionized water, drying at 80° C. for 6 hours, and grinding to an average particle size of 100 nm, nanoporous calcium carbonate is obtained.

preparation example 2

[0046] The difference between this preparation example and the preparation example 1 of nanoporous calcium carbonate is that the consumption of polyvinylpyrrolidone is 0.6kg, the consumption of sodium carbonate is 2.5kg, the consumption of calcium chloride is 1.2kg, and the consumption of sodium lauryl sulfate is 1.2kg. The dosage is 0.3kg.

preparation example 3

[0048] The difference between this preparation example and the preparation example 1 of nanoporous calcium carbonate is that the mixed solution A in step ① is only formed by mixing 1.5 kg of sodium carbonate and 5 kg of water.

[0049] Preparation example of modified montmorillonite

[0050] Unless otherwise specified, the raw materials in the preparation examples can be obtained commercially. The cationic modifier can be dodecyltrimethylammonium bromide, cetyltrimethylammonium bromide, octadecyltrimethylammonium bromide, diddecyldimethylammonium chloride , two hexadecyl dimethyl ammonium chloride dioctadecyl dimethyl ammonium chloride species of one or more mixtures, the cationic modifier of the following preparation examples all select octadecyl trimethyl Ammonium bromide; polyvinylpyrrolidone is polyvinylpyrrolidone K90; montmorillonite is natural montmorillonite with a fineness of 100 mesh.

[0051] Preparation Example 1 of Modified Montmorillonite

[0052] The preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com