Preparation method of carbon-containing alumina carrier

A technology of alumina carrier and alumina carbon oxide, which is applied in the direction of catalyst carrier, chemical instrument and method, catalyst activation/preparation, etc. It can solve the problems that the inner surface cannot be effectively used, the uniformity of carbon coating on the carrier is difficult to guarantee, and environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

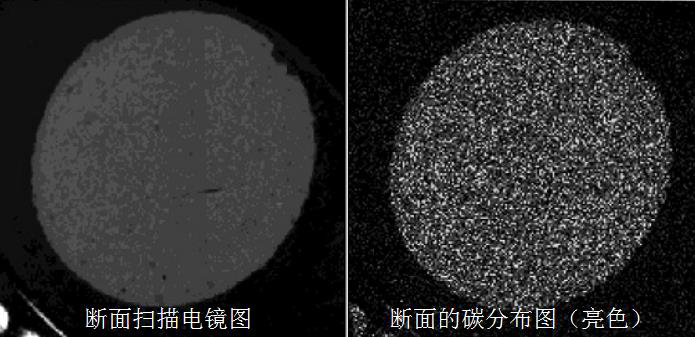

Embodiment 1

[0029] 100 grams of alumina shaped carrier was activated under 300°C air atmosphere for 6 hours, and cooled to room temperature naturally. At room temperature, 32 grams of the liquid material was prepared according to the proportions of water 35%, ethanol 32%, furfuryl alcohol 30%, and oxalic acid 3%. Evaporate at 25°C for 3 hours under a negative pressure of 80kPa, put it into a small microwave oven with a power of 600 watts and heat at 60°C for 10 minutes, then use an oven to dry at 170°C for 12 hours, and finally pass into a tube furnace protected by nitrogen at 550°C The carbon-containing alumina carrier of the present invention is obtained by medium calcination for 3 hours. The obtained product is a cylindrical particle with gray-black surface and cross-section. The electron probe element distribution test shows that the carbon element is evenly distributed. Other properties of the product are shown in Table 1.

Embodiment 2

[0031] 100 grams of alumina shaped carrier was activated under 500°C air atmosphere for 3 hours, and cooled to room temperature naturally. At room temperature, 31 grams of the liquid material was prepared according to the proportions of 48% water, 35% ethanol, 16% furfuryl alcohol, and 1% oxalic acid. After thorough mixing, it was impregnated with the alumina carrier in equal volume. Evaporate at 25°C for 6 hours under a negative pressure of 50kPa, put it into a small microwave oven with a power of 600 watts and heat at 60°C for 10 minutes, then use an oven to dry at 170°C for 12 hours, and finally put it into a tube furnace protected by nitrogen at 550°C The carbon-containing alumina carrier of the present invention is obtained by medium calcination for 3 hours. The obtained product is a cylindrical particle with gray-black surface and cross-section. The electron probe element distribution test shows that the carbon element is evenly distributed. Other properties of the prod...

Embodiment 3

[0033] 100 grams of alumina shaped carrier was activated under 500°C air atmosphere for 3 hours, and cooled to room temperature naturally. At room temperature, 31 grams of the liquid material was prepared according to the proportions of 26% water, 30% ethanol, 40% furfuryl alcohol, and 4% oxalic acid. After thorough mixing, it was impregnated with the alumina carrier in equal volume. Evaporate at 25°C for 6 hours under a negative pressure of 50kPa, put it into a small microwave oven with a power of 600 watts and heat at 60°C for 10 minutes, then use an oven to dry at 170°C for 12 hours, and finally put it into a tube furnace protected by nitrogen at 550°C The carbon-containing alumina carrier of the present invention is obtained by medium calcination for 3 hours. The obtained product is a cylindrical particle with gray-black surface and cross-section. The electron probe element distribution test shows that the carbon element is evenly distributed. Other properties of the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com