Photocuring 3D printing ceramic composite material as well as preparation method and application thereof

A ceramic composite material, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of high brittleness, low strength, limited application, etc., and achieve the effect of improving toughness, good mechanical strength and toughness, and excellent bone repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A light-curing 3D printing ceramic composite material, the preparation raw materials of which include hydroxyapatite ceramic powder, light-curing resin, alumina powder and additives; wherein: the light-curing resin comprises 1,6-hexanediol diacrylate and Benzyl alcohol acrylate; auxiliary agents include dispersant phosphoric acid ester and polyamide, photoinitiator 1-hydroxy-cyclohexyl-phenyl ketone, defoamer polyoxypropylene glyceryl ether and polymerization inhibitor phenothiazine.

[0066] A preparation method of a photocuring 3D printing ceramic composite material, comprising the following steps:

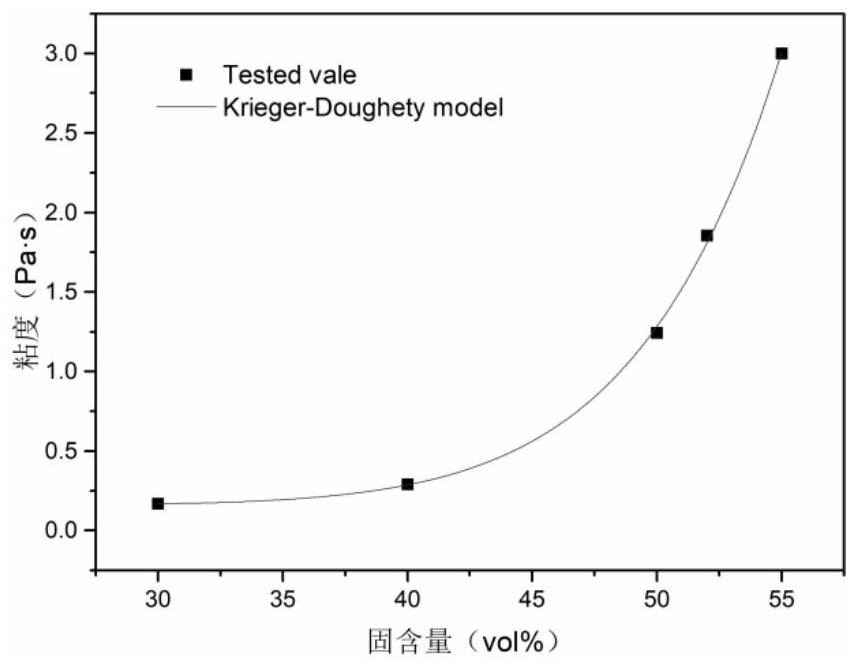

[0067] (1) Preparation of ceramic slurry

[0068] Dry the hydroxyapatite ceramic powder and alumina powder for use;

[0069] To 1,6-hexanediol diacrylate and biphenylmethanol acrylate in a volume ratio of 7:3, first add 3 g of dispersant phosphate and 1 g of polyamide, and then add 0.2 g of photoinitiator 1-hydroxy- Cyclohexyl-phenyl ketones, 0.1 g of polymerization inh...

Embodiment 2

[0082] A light-cured 3D printing ceramic composite material, the preparation raw materials of which include tricalcium phosphate ceramic powder, light-cured resin, zirconia powder and additives; wherein: the light-cured resin includes 1,6-hexanediol diacrylate and biphenyl Methanol acrylate; additives include dispersant phosphoric acid ester and polyacrylate, photoinitiator 2,4,6 (trimethylbenzoyl) diphenylphosphine oxide, defoamer polyoxypropylene glyceryl ether and polymerization inhibitor Emulsified silicone oil.

[0083] A preparation method of a photocuring 3D printing ceramic composite material, comprising the following steps:

[0084] (1) Preparation of ceramic slurry

[0085] Drying tricalcium phosphate ceramic powder and zirconia powder for use;

[0086] In 1,6-hexanediol diacrylate and biphenylmethanol acrylate in a volume ratio of 5:5, first add 3 grams of dispersant phosphate and 1 gram of polyamide, and then add 0.2 grams of photoinitiator 2,4, 6 (trimethylbenz...

Embodiment 3

[0099] A light-curing 3D printing ceramic composite material, the preparation raw materials of which include hydroxyapatite ceramic powder, light-curing resin, zirconia powder and additives; wherein: the light-curing resin comprises 1,6-hexanediol diacrylate and ortho Phenylphenoxyethyl acrylate; additives include dispersant phosphate ester, photoinitiator 2,4,6(trimethylbenzoyl)diphenylphosphine oxide, defoamer polyoxypropylene glyceryl ether and paraben Hydroxyanisole inhibitor.

[0100] A preparation method of a photocuring 3D printing ceramic composite material, comprising the following steps:

[0101] (1) Preparation of ceramic slurry

[0102] Dry the hydroxyapatite ceramic powder and zirconia powder for use;

[0103] In the mixed resin of 1,6-hexanediol diacrylate and o-phenylphenoxyethylacrylate with a volume ratio of 6:4, first add 4 grams of dispersant phosphate, and then add 0.2 grams of photoinitiator 2,4 , 6 (trimethylbenzoyl) diphenylphosphine oxides, 0.1 gram ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com