Decorative material and preparation method thereof

A technology of decorative materials and composite materials, applied in the field of decorative materials and their preparation, can solve the problems of poor formaldehyde adsorption performance, achieve the effects of improving antibacterial performance, enriching pore structure, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

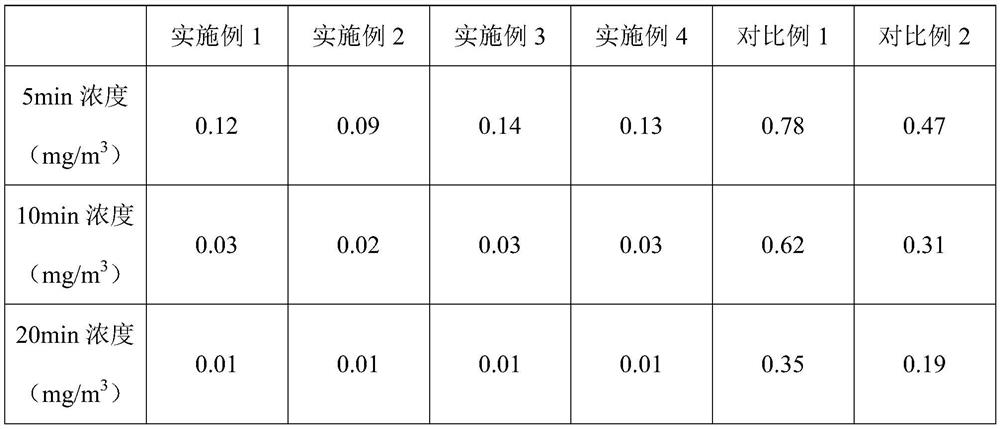

Examples

Embodiment 1

[0031] A preparation method of a decorative material, comprising the following steps:

[0032] (1) Pretreatment of rectorite: 10g rectorite and 10g NaOH solid are ground and mixed uniformly, then calcined at 750°C for 1 h, and the calcined product is sieved to obtain pretreated rectorite;

[0033] (2) Preparation of modified rectorite: 10 g of pretreated rectorite was added to 40 g of dilute hydrochloric acid of 10 wt %, stirred at 60° C. for 1 h, and after stirring, filtered, washed and dried to obtain modified rectorite. sex rectorite;

[0034] (3) Preparation of modified activated carbon: 5g activated carbon was added to 15g (3-chloro-2-hydroxypropyl) trimethylammonium chloride solution, stirred and mixed evenly at room temperature, then heated to 35°C, added NaOH solution, adjust the pH of the solution to 8.5, react for 12 hours, after the reaction is completed, cool to room temperature, adjust the pH of the solution to be acidic, and then wash and dry the reaction produc...

Embodiment 2

[0038] A preparation method of a decorative material, comprising the following steps:

[0039] (1) Pretreatment of rectorite: 10g of rectorite and 12g of NaOH solid are ground and mixed uniformly, then calcined at 800°C for 2 hours, and the calcined product is sieved to obtain pretreated rectorite;

[0040] (2) Preparation of modified rectorite: 10 g of pretreated rectorite was added to 60 g of 15wt% dilute hydrochloric acid, stirred at 80°C for 1 h, after stirring, filtered, washed and dried to obtain modified rectorite. sex rectorite;

[0041] (3) Preparation of modified activated carbon: 5g of activated carbon was added to 18g of (3-chloro-2-hydroxypropyl) trimethylammonium chloride solution, stirred and mixed evenly at room temperature, then heated to 40°C, and NaOH was added. solution, adjust the pH of the solution to 8.5, react for 14 hours, after the reaction is completed, cool to room temperature, adjust the pH of the solution to be acidic, and then wash and dry the r...

Embodiment 3

[0045] A preparation method of a decorative material, comprising the following steps:

[0046] (1) Pretreatment of rectorite: 10g rectorite and 15g NaOH solid are ground and mixed uniformly, then calcined at 750°C for 2 hours, and the calcined product is sieved to obtain pretreated rectorite;

[0047] (2) Preparation of modified rectorite: 10 g of pretreated rectorite was added to 80 g of dilute hydrochloric acid of 10 wt %, stirred at 65° C. for 2 h, after stirring, filtered, washed and dried to obtain modified rectorite. sex rectorite;

[0048] (3) Preparation of modified activated carbon: 5g of activated carbon was added to 16g of (3-chloro-2-hydroxypropyl) trimethylammonium chloride solution, stirred and mixed evenly at room temperature, then heated to 40° C., and NaOH was added. solution, adjust the pH of the solution to 8.5, react for 16h, after the reaction is completed, cool to room temperature, adjust the pH of the solution to be acidic, and then wash and dry the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com