Method for purifying glycyrrhizic acid by using preparative chromatography technology

A technology of glycyrrhizic acid and chromatography, which is applied in the field of separation and purification of herbal medicinal components, can solve the problems of narrow separation range, large amount of solvent treatment, cumbersome process, etc., and achieves easy industrial production, low solvent consumption, and good separation selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

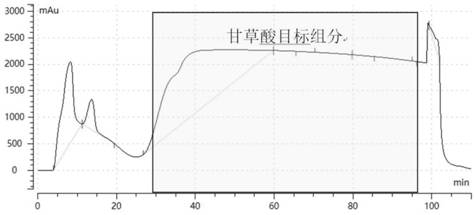

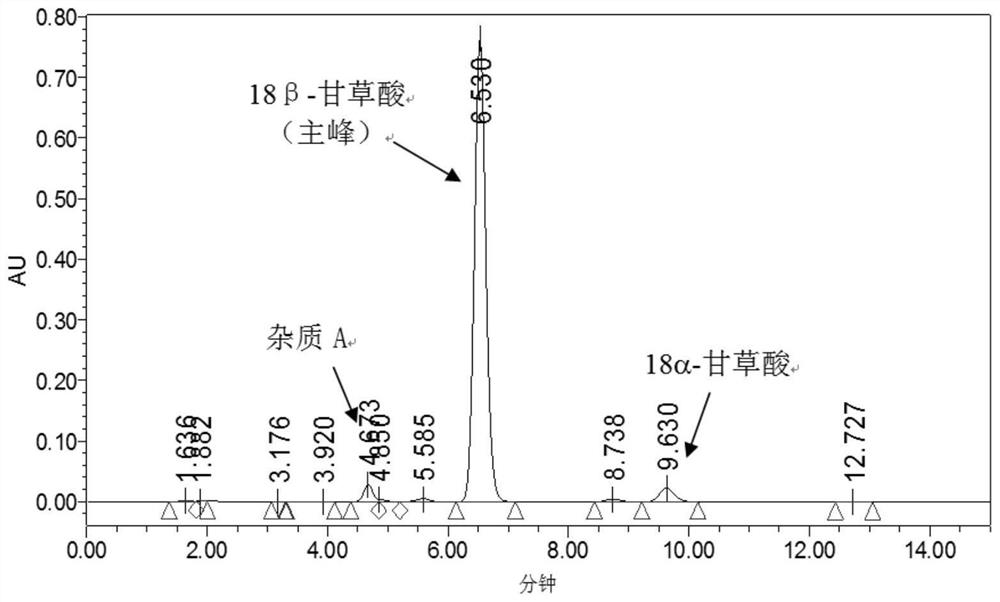

Embodiment 1

[0034] 15 g of glycyrrhizic acid extract was dissolved in 300 mL of 50% acetone water to prepare a sample solution with a concentration of 50 mg / mL, and the sample loading amount was 5%. Using polar groups to modify silica gel (C18 connected diamino modified packing, the bonding amount is 2.28μmol / m 2 ) packed chromatographic column (column size 50×250mm, particle size 30μm, pore size Filler mass 300g). Elute with acetone: acetic acid water (1%, v / v)=10:90, flow rate 50mL / min, collect 30~98min according to the peak shape curve after the target peak, the target analytical solution is concentrated and dried by the prior art, the obtained The content of glycyrrhizic acid in the product is 91.76% (the related substance impurity A is 2.51%, the isomer impurity 18α glycyrrhizic acid is 3.11%), and the yield is 93.8%.

Embodiment 2

[0036] 5 g of glycyrrhizic acid extract was added into 50 mL of 50% methanol water to dissolve, and the sample solution with a concentration of 100 mg / mL was prepared, and the sample loading amount was 10%. Silica gel modified with polar groups (C8-linked amide modified packing, the bonding amount is 2.41 μmol / m 2 ) packed chromatographic column (column size 20×250mm, particle size 10μm, pore size Filler mass 50g). Elute with methanol: formic acid water (0.5%, v / v)=20:80, flow rate 50mL / min, collect 35-90min according to the peak shape curve after the target peak, the target analytical solution is concentrated and dried by the prior art, the obtained The content of glycyrrhizic acid in the product is 93.25% (the related substance impurity A is 2.08%, the isomer impurity 18α glycyrrhizic acid is 2.86%), and the yield is 92.5%.

Embodiment 3

[0038]10 kg of glycyrrhizic acid extract was added to dissolve in 100 L of 50% ethanol water to prepare a sample solution with a concentration of 100 mg / mL, and the sample loading amount was 8%. Modified silica gel with polar groups (C4-linked amino-modified packing, the bonding amount is 2.69 μmol / m 2 ) packed chromatographic column (column size 1000×250mm, particle size 30μm, pore size Filler mass 120kg). Elute with ethanol: oxalic acid water (2%, v / v)=25:75, flow rate 20L / min, collect 32~98min according to the peak shape curve after the target peak, the target analytical solution is concentrated and dried by the prior art, the obtained The content of glycyrrhizic acid in the product is 93.25% (the related substance impurity A is 2.08%, the isomer impurity 18α glycyrrhizic acid is 2.48%), and the yield is 90.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com