Medium-strength and high-toughness titanium alloy with yield strength of 800MPa for ocean engineering and preparation process of medium-strength and high-toughness titanium alloy

A technology of yield strength and marine engineering, which is applied in the field of marine engineering, titanium alloy and its forming process, can solve the problems of unremarkable special performance of marine engineering, unsuitable for large-scale application in the marine field, and high comprehensive cost, so as to ensure structural safety, Improved structural safety and high stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0040] According to the alloy target control composition in Table 1, three kinds of Ti-Al-Mo-Cr-V-Sn-Zr titanium alloy ingots with different chemical compositions were smelted, the ingot weight was 700kg and the diameter was 380mm. The chemical compositions of the upper and lower parts of the three alloy ingots actually tested are shown in Table 2. After metallographic detection, it was found that the transformation points of the three alloys were 920±5℃ for 1# alloy, 950±5℃ for 2# alloy, and 950±5℃ for 3# alloy. The alloy ingots are successively subjected to billet forging in the β single-phase region, upsetting and drawing in the β single-phase region, forging in the α+β two-phase region, one-time thermal deformation in the β single-phase region, and ordinary annealing heat treatment. The specific process is as follows:

[0041] (1) According to the ratio of each alloy element in Table 1, the raw materials such as titanium sponge, aluminum-vanadium alloy, titanium-tin alloy,...

Embodiment 2

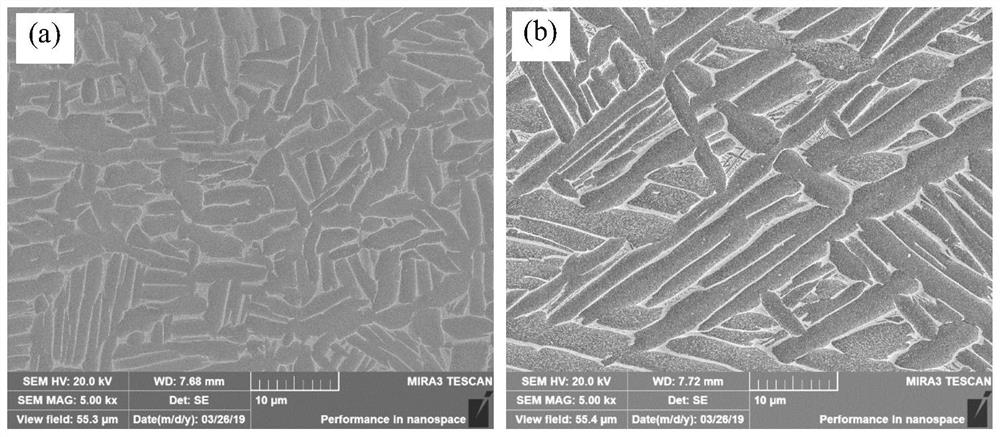

[0065] In Example 2, on the basis of Example 1, the content of Mo was reduced from 3% to 1% by weight, and the content of Sn was reduced from 2% to 1%. By comparing Table 3 and Table 5, it can be found that due to the weakening of the solid solution strengthening effect of solute elements, the strength of the alloy decreases (such as image 3 ), however, the ductility and toughness of the alloy did not decrease, especially the room temperature impact performance was significantly improved (such as Figure 4 shown). Therefore, the strength-toughness matching of the alloy can be optimized under the premise of reducing the production cost by appropriately reducing the content of Mo element and Sn element with weak solid solution strengthening effect.

Embodiment 3

[0066] In Example 3, based on Example 2, the content of Mo was increased from 1% to 1.5% by weight, and the content of Al was slightly increased. By comparing Table 5 and Table 7, it can be found that the solid solution strengthening effect of Mo element is strong, and the strength of the alloy is significantly improved, while the toughness of the alloy does not decrease. Therefore, by fine-tuning the content of Mo element in the alloy, the strength-toughness matching of the new alloy is further improved.

[0067] The new titanium alloy can be subjected to ordinary annealing heat treatment in a wide temperature range, and can achieve medium-strength and high toughness under ordinary annealing conditions. It can be seen from Tables 3 to 6 that the ordinary annealing temperature has little effect on the mechanical properties of the alloy at room temperature. After ordinary annealing at 540°C to 780°C, only the strength of the 2# alloy decreases when annealed at a higher temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com