Graphene RFID tag and preparation method and application thereof

A technology of graphene and conductive paste, applied in the field of radio frequency identification, can solve the problems of easy damage of labels, poor mechanical, chemical and thermal stability of metal labels, etc., and achieve the effect of superior conductivity, high dispersion performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

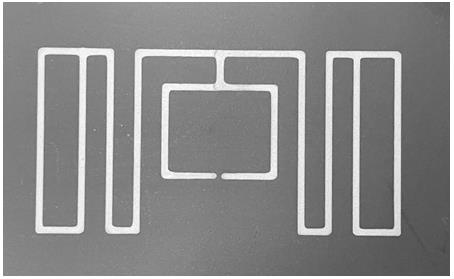

Image

Examples

Embodiment 1

[0048] Example 1 Preparation of graphene conductive paste

[0049] 1. Preparation of graphene:

[0050] Concentrated sulfuric acid and concentrated phosphoric acid were mixed in an 8:1 volume ratio and immersed in an ice-water bath to cool. Then, the natural flake graphite and potassium permanganate were mixed uniformly at a weight ratio of 1:3, poured into the mixed acid, stirred and reacted for 2 hours, removed from the ice bath, and reacted in a water bath at 45 °C for 30 minutes. After that, it was moved into the ice bath again, and deionized water equal to the volume of concentrated sulfuric acid was added dropwise with stirring. After the reaction, 3% hydrogen peroxide solution was added until the liquid changed from tan to pale yellow and no gas was produced. After centrifugation, removing the supernatant, adding the same volume of deionized water, ultrasonic dispersion, dialysis, and drying in an oven at 70° C. to obtain flake graphite oxide.

[0051] After grinding t...

Embodiment 2

[0055] Weigh 4g of 10mg / ml graphene dispersion liquid, put it into the syringe barrel, connect it with the nozzle and install it on the three-axis CNC platform, open the air pressure control system, then fix the PET matrix on the heating plate, and use the computer to set the nozzle to move. Set the speed to 5, set the nozzle movement route, set the slurry extrusion speed to 100 microliters per minute, turn on the heating plate, set the heating plate temperature to 100 °C, and start running after the heating plate temperature rises and stabilizes at 100 °C , the graphene conductive paste is extruded from the nozzle and formed on the substrate through a screw extrusion or pneumatic pressure control system.

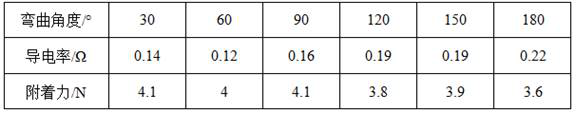

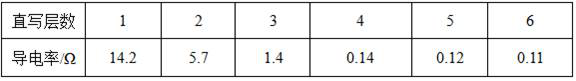

[0056] Put the formed antenna circuit into the ion sputtering apparatus, set the sputtering time for 5 minutes, and test the conductivity as shown in Table 1.

Embodiment 3

[0058] Weigh 4g of 20mg / ml graphene dispersion liquid, put it into the syringe barrel, connect it with the nozzle and install it on the three-axis CNC platform, open the air pressure control system, then fix the PP substrate on the heating plate, and use the computer to set the nozzle to move. Set the speed to 5, set the nozzle movement route, set the slurry extrusion speed to 100 microliters per minute, turn on the heating plate, set the heating plate temperature to 100 °C, and start running after the heating plate temperature rises and stabilizes at 100 °C , the graphene conductive paste is extruded from the nozzle and formed on the substrate through a screw extrusion or pneumatic pressure control system.

[0059] Put the formed antenna circuit into the ion sputtering apparatus, set the sputtering time for 5 minutes, and test the conductivity as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com