Method for synthesizing carbon nano tube based on iron-cobalt-aluminum catalyst with layered structure

A layered structure and nanotube technology, applied in the field of chemistry, can solve the problems of difficulty in dispersion and processing, unfavorable carbon nanotube performance, etc., and achieve the effects of easy purification, good electrical conductivity, and low ferromagnetic metal impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

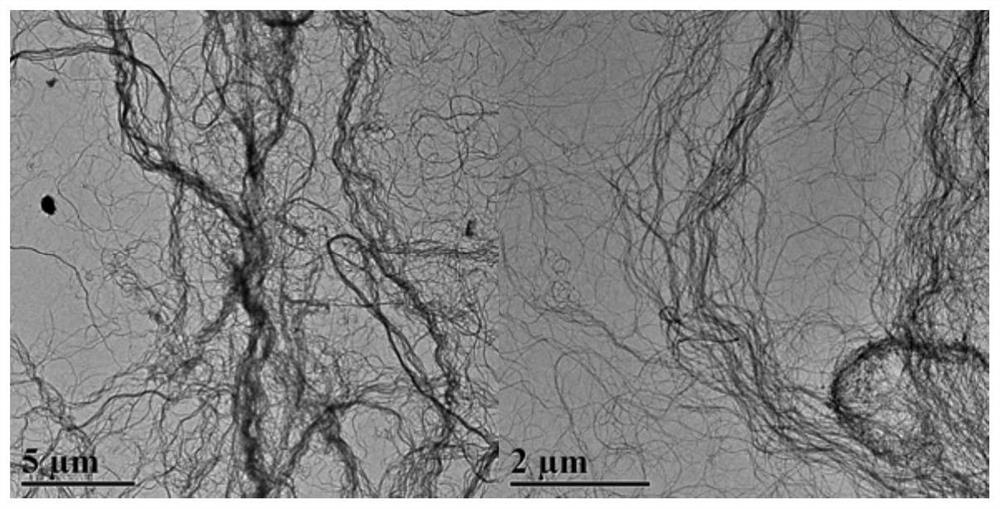

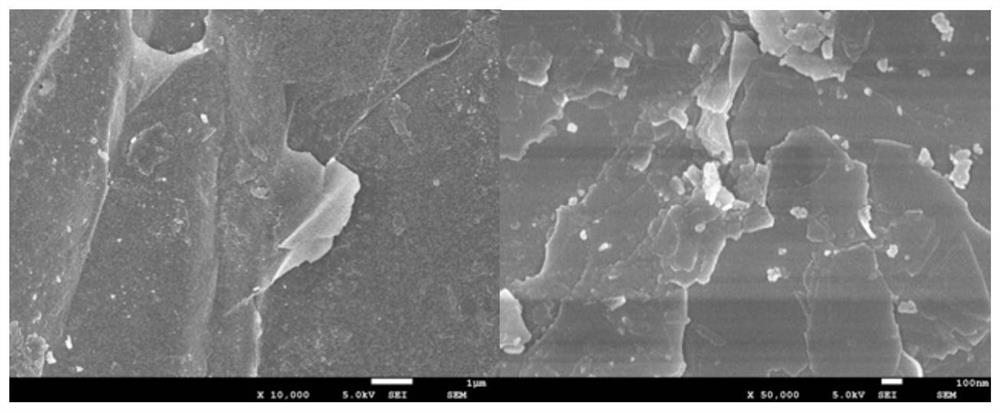

Image

Examples

Embodiment 1

[0043] (1) prepare iron cobalt aluminum catalyst:

[0044] Pretreatment of vermiculite particles: golden yellow flaky vermiculite (produced in Hebei) with a particle size of 3-8mm was heat-treated at 1000 °C for 10 seconds, expanded into small worms, and then immersed in 2mol / L ammonium citrate solution, and subjected to heat treatment at 1000 °C 10 seconds, the secondary fully expanded into a long worm shape; use a hammer crusher to crush the worm-shaped vermiculite into a size of 1-3mm, and use a cyclone to separate and remove the unexpanded vermiculite and metal impurities with a high density. The 15000GS electromagnetic dry powder iron remover removes ferromagnetic particles; then add pure water according to the weight ratio of vermiculite: pure water = 1:5, stir the mixture until it has a certain fluidity, and remove the sediment associated with vermiculite through a 120-mesh screen , to obtain pretreated vermiculite particles;

[0045] Preparation of salt solution: Weig...

Embodiment 2

[0051] (1) prepare iron cobalt aluminum catalyst:

[0052] Pretreated vermiculite particles: the same as in Example 1;

[0053] Preparation of salt solution: Weigh 20.2g of ferric nitrate nonahydrate, 6.4g of cobalt nitrate nonahydrate, and 27g of aluminum nitrate nonahydrate into a 1L beaker, add 400g of pure water, and stir at room temperature for 20min to completely dissolve the nitrate solution. Add 50 g of pretreated vermiculite particles to the beaker, and use a plate paddle to stir and immerse at low speed at room temperature for 10 hours; after the vermiculite is fully immersed in the salt solution and sinks to the bottom,

[0054] To prepare lye solution: Weigh 260 g of 25%wt ammonia water, 6.18 g of ammonium heptamolybdate tetrahydrate, and 184 g of pure water to prepare a dilute aqueous ammonia solution;

[0055] Preparation of catalyst: add 50g of pretreated vermiculite particles to the beaker, and use a plate paddle at room temperature (room temperature 25°C) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Powder resistance | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com