Lightweight aluminum alloy template and preparation method thereof

An aluminum alloy formwork, lightweight technology, applied in the field of aluminum alloy formwork, can solve the problems of reduced service life, weakened strength, bending and deformation of aluminum alloy formwork, etc., to achieve extended service life, good bearing capacity, and high alloy strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

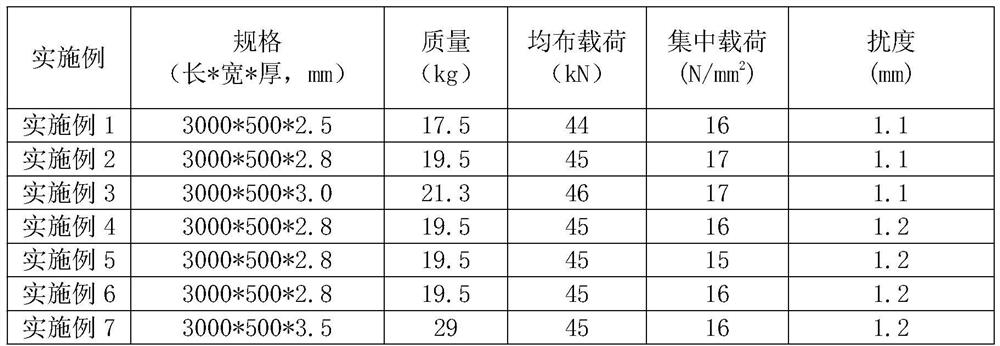

Examples

Embodiment 1

[0023] In this embodiment, the preparation of a lightweight aluminum alloy template includes the following steps:

[0024] S1. Heat 92.5kg of metallic aluminum to 660°C to melt, then add 0.2kg of nano-silicon carbide, stir evenly, then add 0.5kg of nano-zinc oxide, 1.5kg of nano-titanium dioxide and 0.6kg of nano-Ni under stirring , and heated up to 1850°C, stirring at a high speed for 10 minutes, while stirring at a high speed, applying ultrasonic vibration to the first molten liquid, the frequency of the ultrasonic wave is 30KHz, standing at 660°C for 10 hours, to obtain the first molten liquid;

[0025] S2. At a temperature of 1850°C, add 2.5kg of zinc, 1.2kg of copper, 0.8kg of magnesium, and 0.2kg of zirconium to the first molten liquid in sequence, stir for 1 hour, then cool to 650°C and stand for 15 minutes , to obtain the second mixed solution;

[0026] S3. Pouring and rolling the second mixed molten liquid into an aluminum alloy plate with a thickness of 2.5mm, and t...

Embodiment 2

[0029] In this embodiment, the preparation of a lightweight aluminum alloy template includes the following steps:

[0030] S1. Heat 87.9kg of metallic aluminum to 670°C to melt, then add 0.35kg of nano-silicon carbide, and after stirring evenly, add 1.0kg of nano-zinc oxide, 1.7kg of nano-titanium dioxide and 0.95kg of nano-Ni in a stirring state. , and raised the temperature to 1875°C, stirred at a high speed for 15 minutes, and applied ultrasonic vibration to the first molten liquid during high-speed stirring, the frequency of the ultrasonic wave was 35KHz, and stood at 670°C for 12.5 hours to obtain the first molten liquid;

[0031] S2. At a temperature of 1875°C, add 4.5kg of zinc, 1.7kg of copper, 1.2kg of magnesium, and 0.5kg of zirconium to the first molten liquid in sequence, stir for 1.5h, then cool to 670°C and stand for 20min Afterwards, the second mixed solution is obtained;

[0032] S3. Pouring and rolling the second mixed molten liquid into an aluminum alloy pla...

Embodiment 3

[0035] In this embodiment, the preparation of a lightweight aluminum alloy template includes the following steps:

[0036] S1. Heat 83.3kg of metal aluminum to 680°C to melt, then add 0.5kg of nano-silicon carbide, and after stirring evenly, add 1.5kg of nano-zinc oxide, 1.9kg of nano-titanium dioxide and 1.3kg of nano-Ni in a stirring state. , and raised the temperature to 1900°C, stirred at high speed for 20 minutes, and applied ultrasonic vibration to the first molten liquid during high-speed stirring, the frequency of the ultrasonic wave was 40KHz, and stood at 680°C for 15 hours to obtain the first molten liquid;

[0037] S2. At a temperature of 1900°C, add 6.5kg of zinc, 2.6kg of copper, 1.6kg of magnesium, and 0.8kg of zirconium to the first molten liquid in sequence, stir for 2 hours, then cool to 680°C and stand for 25 minutes , to obtain the second mixed solution;

[0038]S3. Pouring and rolling the second mixed molten liquid into an aluminum alloy plate with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com