Iron-nickel-cobalt glass-sealing alloy

An iron-nickel-cobalt glass seal and alloy technology, which is applied in the field of metal materials, can solve the problems of easy cracking and micro-cracks of the nail head, reduce defects that cannot be eliminated by manual grinding, improve the ability and desulfurization ability of the alloy, and improve the quality of the alloy. quality effect

Inactive Publication Date: 2019-08-16

DANYANG HUALONG SUPERIOR STEEL

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to avoid the problem that the current iron-nickel-cobalt glass-sealing alloy is easy to crack and form micro-cracks, the invention discloses an

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

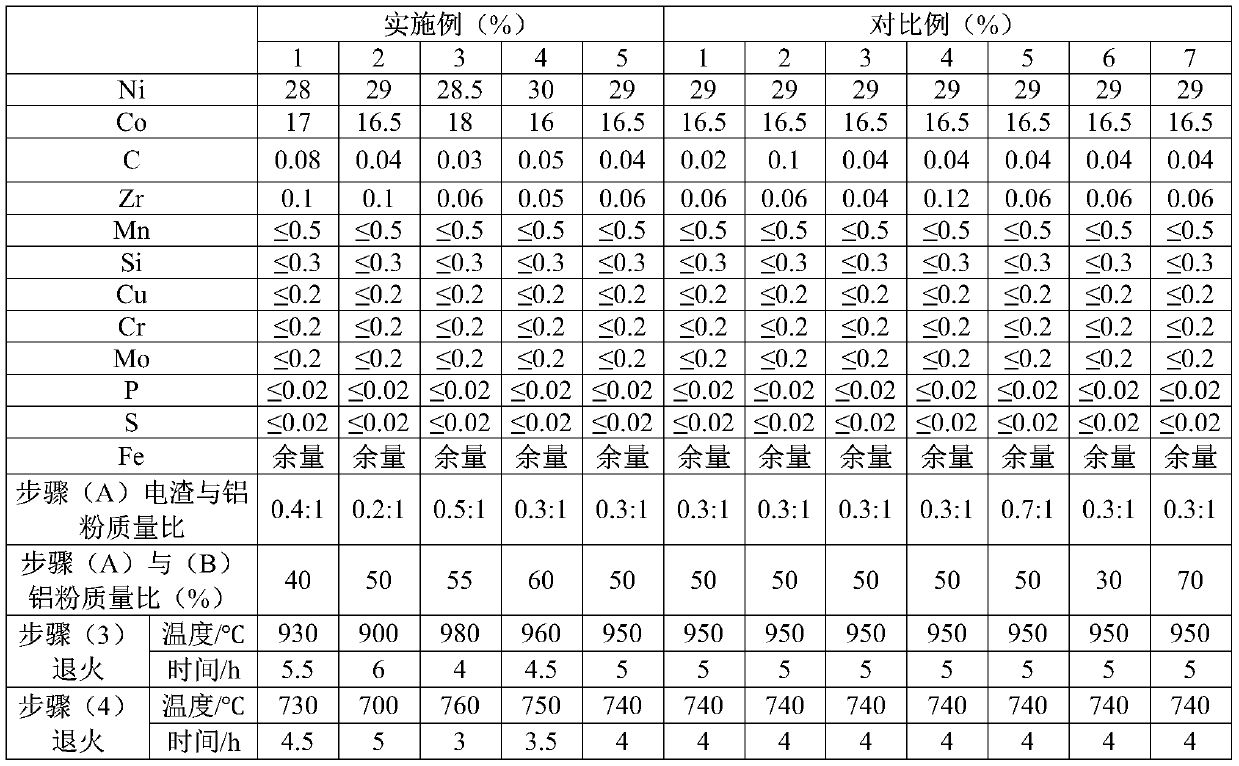

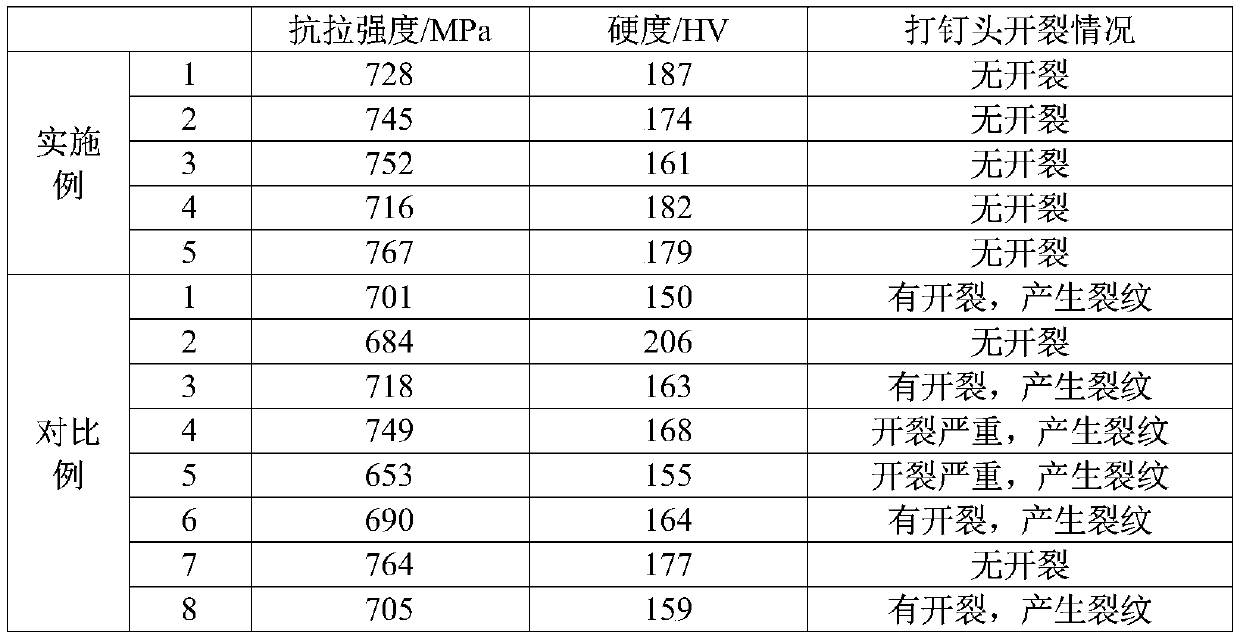

The invention belongs to the technical field of metal materials, and particularly relates to an iron-nickel-cobalt glass-sealing alloy. The iron-nickel-cobalt glass-sealing alloy comprises the following components of, by mass, 28%-30% of Ni, 16%-18% of Co, 0.03%-0.08% of C, 0.05%-0.1% of Zr, less than or equal to 0.5% of Mn, less than or equal to 0.3% of Si, less than or equal to 0.2% of Cu, lessthan or equal to 0.2% of Cr, less than or equal to 0.2% of Mo, less than or equal to 0.02% of P, less than or equal to 0.02% of S and the balance Fe, wherein the mass ratio of the C to the Zr is 1:1-2.5. According to the iron-nickel-cobalt glass-sealing alloy, the proportion of the carbon and the zirconium in the alloy is properly improved, and the mass ratio of the carbon and the zirconium in thealloy is limited, so that the alloy strength is effectively improved, and the situation that the alloy is cracked during nail head striking, and micro cracks are formed is avoided; in the electroslagremelting process, an appropriate amount of aluminum powder is used for carrying out deoxidation treatment on electroslag so that unstable oxides such as FeO and MnO in the electroslag can be reduced, then the oxygen content in the alloy is effectively reduced, adverse effects are avoided, the non-metal inclusion adsorption capability and the desulfurization capability of the slag are also improved, and the alloy quality is improved; and peeling treatment is performed before hot rolling, so that the pickling process is omitted, environmental protection is facilitated, the surface quality of the material can be improved through peeling, the defects which cannot be eliminated through manual grinding are reduced, and the quality of the alloy is improved.

Description

technical field [0001] The invention belongs to the technical field of metal materials, and in particular relates to an iron-nickel-cobalt glass sealing alloy. Background technique [0002] Iron-nickel-cobalt glass sealing alloy is widely used in electric vacuum devices, such as launch tubes, oscillating tubes, transistors, etc., and is a sealing structure material that matches the expansion coefficient of glass. The airtightness requirements are quite strict, and various types of defects such as the compactness of the material structure, the inclusion of pores with cracks, the inconsistency of the sintering softness and hardness of the material, and other types of defects must be strictly controlled in each process of the processing process. [0003] At present, the strength of the domestic iron-nickel-cobalt glass sealing alloy is low, and the nail head is easy to crack to form micro-cracks. Moreover, the current iron-nickel-cobalt glass sealing alloy is generally electros...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/10C22C38/08C22C38/14C22C38/04C22C38/02C22C38/16C22C38/12C22C38/52C22C38/50C22C38/42C22C38/44C22B9/18C21D8/06

CPCC21D8/065C22B9/18C22C38/02C22C38/04C22C38/105C22C38/12C22C38/14C22C38/16C22C38/42C22C38/44C22C38/50C22C38/52Y02P10/25

Inventor 蒋红军

Owner DANYANG HUALONG SUPERIOR STEEL

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com