A nickel-copper alloy with excellent low-temperature impact properties and its production process

A nickel-copper alloy, low-temperature impact technology, applied in the field of alloy materials, can solve problems such as unreasonable element composition, poor low-temperature impact performance, and unsatisfactory toughness requirements, and achieve quantitative dispersion, low-temperature impact performance improvement, and comprehensive mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

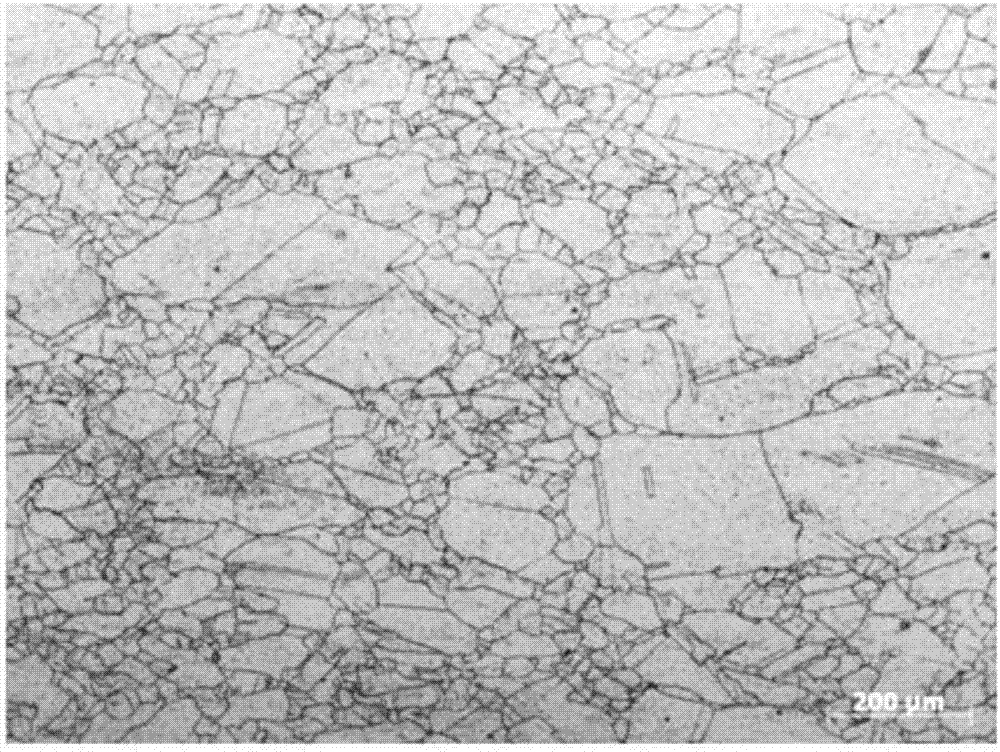

Embodiment 1

[0044] This embodiment provides a nickel-copper alloy, its composition weight percent is: Cu: 30.5%, Al: 2.88%, Ti: 0.47%, Mn: 1.18%, Si: 0.35%, C: 0.06%, S: 0.002 %; the balance is Ni.

[0045] The production technology of this nickel-copper alloy comprises the following steps:

[0046] Get the raw material, the weight percentage of the raw material is composed of: 31% Cu, 3% electrolytic aluminum, 0.5% pure titanium, 1.2% electrolytic manganese, 0.37% pure silicon, 0.07% carbon powder, and the remaining electrolytic nickel ;The raw material is smelted in a vacuum intermediate frequency melting furnace at 1550-1650°C to produce a melt, and a small amount of magnesium copper is added as a degasser during the smelting process;

[0047] The melt is refined at 1600°C for 45 minutes;

[0048] Stand still at 1550°C for 30 minutes after refining;

[0049] After cooling down to 1520°C, pour it into a cast iron mold and cool to room temperature to obtain an ingot;

[0050] Carry o...

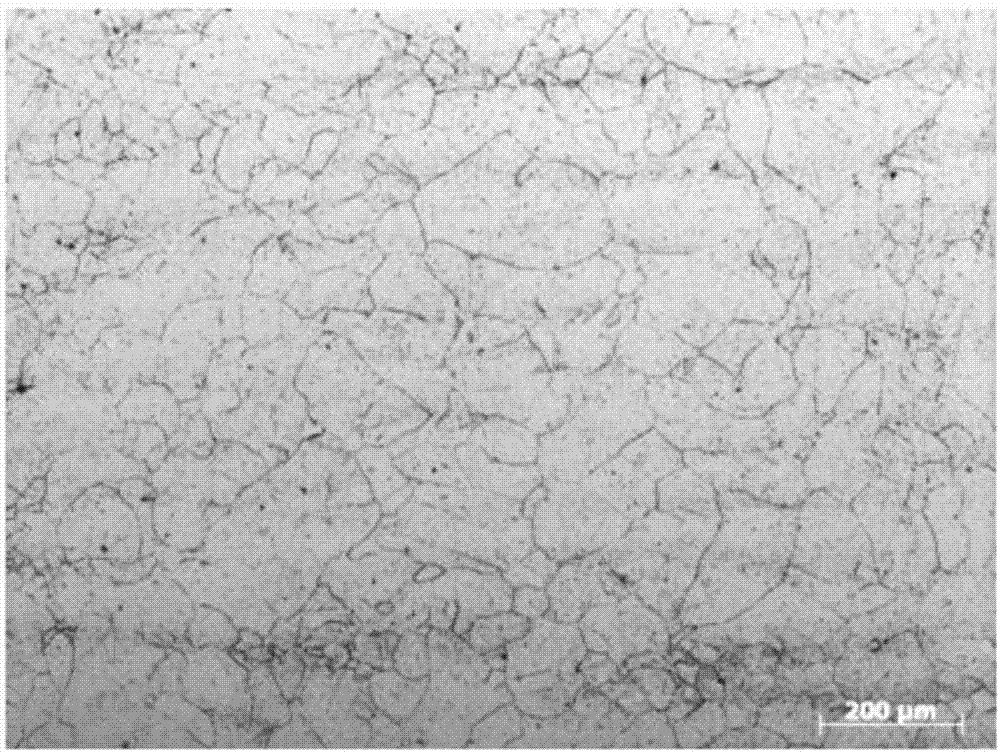

Embodiment 2

[0054] This embodiment provides a nickel-copper alloy, its composition weight percent is: Cu: 32.5%, Al: 3.2%, Ti: 0.6%, Mn: 1.28%, Si: 0.38%, C: 0.085%, S: 0.001 %; the balance is Ni.

[0055] The production technology of this nickel-copper alloy comprises the following steps:

[0056] Get the raw material, the weight percentage of the raw material is composed of: 33% Cu, 3.5% electrolytic aluminum, 0.7% pure titanium, 1.3% electrolytic manganese, 0.4% pure silicon, 0.1% carbon powder, and the remaining electrolytic nickel ;The raw material is smelted in a vacuum intermediate frequency melting furnace at 1580-1650°C to produce a melt, and a small amount of magnesium copper is added as a degasser during the smelting process;

[0057] The melt is refined at 1600°C for 45 minutes;

[0058] Stand still at 1550°C for 30 minutes after refining;

[0059] After cooling down to 1520°C, pour it into a cast iron mold and cool to room temperature to obtain an ingot;

[0060] Carry ou...

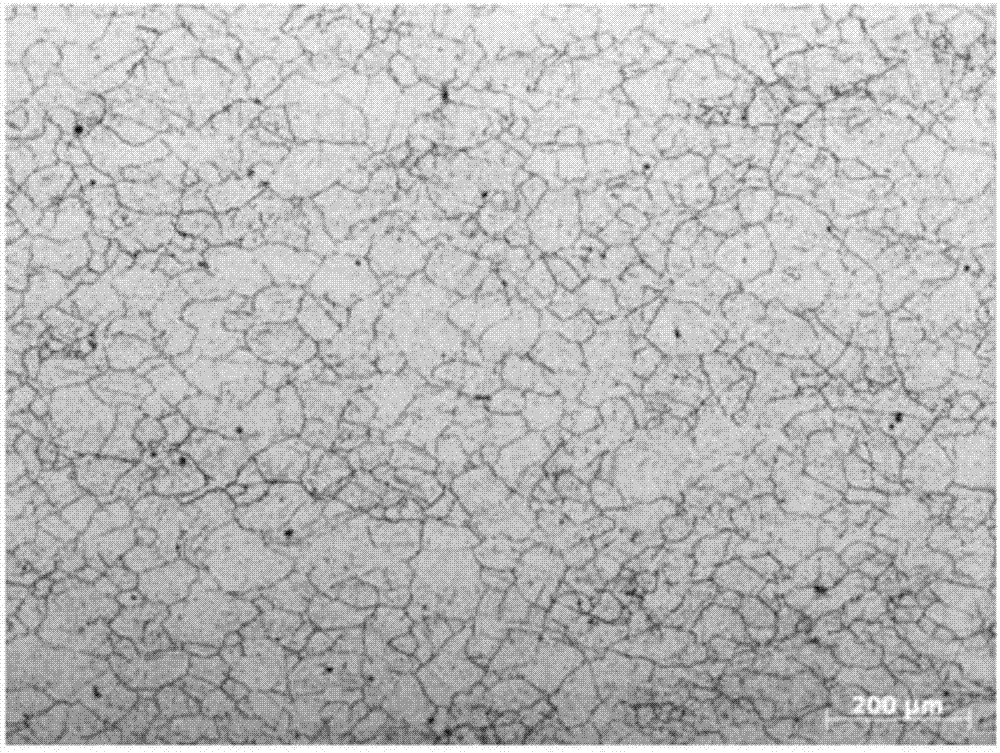

Embodiment 3

[0064] This embodiment provides a nickel-copper alloy, its composition weight percent is: Cu: 28.5%, Al: 2.74%, Ti: 0.52%, Mn: 1.18%, Si: 0.33%, C: 0.057%, S: 0.002 %; the balance is Ni.

[0065] The production technology of this nickel-copper alloy comprises the following steps:

[0066] Get the raw material, the weight percentage of the raw material is composed of: 29% Cu, 2.9% electrolytic aluminum, 0.6% pure titanium, 1.2% electrolytic manganese, 0.35% pure silicon, 0.07% carbon powder, and the remaining electrolytic nickel ;The raw material is smelted in a vacuum intermediate frequency melting furnace at 1500-1600°C to produce a melt, and a small amount of magnesium copper is added as a degasser during the smelting process;

[0067] The melt is refined at 1580°C for 40 minutes;

[0068] Stand still at 1530°C for 30 minutes after refining;

[0069] After cooling down to 1500°C, pour it into a cast iron mold and cool to room temperature to obtain an ingot;

[0070] Carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com