Preparation method of dispersed fluffy MB6 nano low-heat-transfer powder material

A kind of powder material and nanotechnology, which is applied in the field of preparation of evacuated and fluffy MB6 nanometer low heat transfer powder material, can solve the problems of difficult separation and purification of powder, long atomic diffusion path, incomplete reaction, etc., and achieve high added value of products , controllable particle size and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

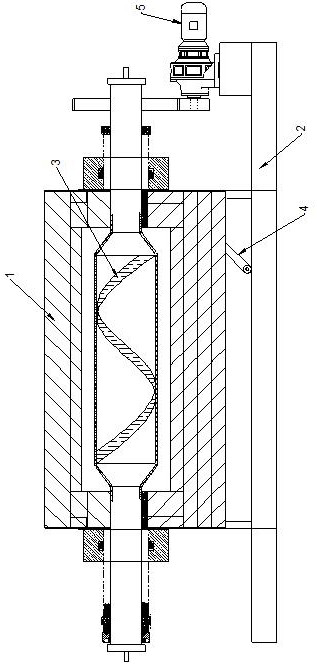

Image

Examples

Embodiment 1

[0036] An evacuated fluffy CaB 6 The preparation method of nanometer low heat transfer powder material comprises the following steps:

[0037] (1) According to the ratio of Ca:B molar ratio of 1:6, weigh CaCO 3 1010g, B 2 O 3 2089g put it and 6kg deionized water into a sand mill and grind for 8 hours to obtain a 146nm powder precursor;

[0038](2) The precursor is loaded into the rotary furnace, and the filling height of the precursor is 3 cm. After the sealed rotary furnace is filled with 8% hydrogen-nitrogen gas at a rate of 100 mL / min for 1 min, the temperature starts to rise. The first heating stage: room temperature To 200°C, the heating rate is 7°C / min, keep warm for 30min, the ventilation rate is 2mL / min, the inclination angle of the rotary furnace is 15°, and the rotation rate is 10rpm; the second heating stage: from 200°C to 470°C, the heating rate is 7°C / min, heat preservation 30min, ventilation rate 5mL / min, rotary furnace inclination angle 10°, rotation spee...

Embodiment 2

[0042] An evacuated fluffy EuB 6 The preparation method of nanometer low heat transfer powder material comprises the following steps:

[0043] (1) According to the ratio of Eu:B molar ratio of 1:6, weigh Eu(NO 3 ) 3 3380g, B2O3 2089g, put it and 6kg deionized water into a sand mill and grind for 8 hours to obtain a 142nm powder precursor;

[0044] (2) The precursor is loaded into the rotary furnace, and the filling height of the precursor is 3 cm. After the sealed rotary furnace is filled with 8% hydrogen-nitrogen gas at a rate of 100 mL / min for 1 min, the temperature starts to rise. The first heating stage: room temperature To 200°C, the heating rate is 7°C / min, keep warm for 30min, the ventilation rate is 2mL / min, the inclination angle of the rotary furnace is 15°, and the rotation rate is 10rpm; the second heating stage: from 200°C to 470°C, the heating rate is 7°C / min, heat preservation 30min, ventilation rate 5mL / min, rotary furnace inclination angle 10°, rotation sp...

Embodiment 3

[0048] A loose fluffy SmB 6 The preparation method of nanometer low heat transfer powder material comprises the following steps:

[0049] (1) According to the ratio of Sm:B molar ratio of 1:6, weigh SmCl respectively 3 2567.2g, B 2 o 3 2089g put it and 6kg deionized water into a sand mill and grind for 8.5 hours to obtain a 143nm powder precursor;

[0050] (2) The precursor is loaded into the rotary furnace, and the filling height of the precursor is 3 cm. After the sealed rotary furnace is filled with 8% hydrogen-nitrogen gas at a rate of 100 mL / min for 1 min, the temperature starts to rise. The first heating stage: room temperature To 200°C, the heating rate is 7°C / min, keep warm for 30min, the ventilation rate is 2mL / min, the inclination angle of the rotary furnace is 15°, and the rotation rate is 10rpm; the second heating stage: from 200°C to 470°C, the heating rate is 7°C / min, heat preservation 30min, ventilation rate 5mL / min, rotary furnace inclination angle 10°, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com