Electrocatalytic composite material based on bacterial cellulose as well as preparation method and application of electrocatalytic composite material

A technology of bacterial cellulose and composite materials, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as unsatisfactory catalytic effect and poor stability, and achieve the effect of avoiding agglomeration and aggregation, low cost and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

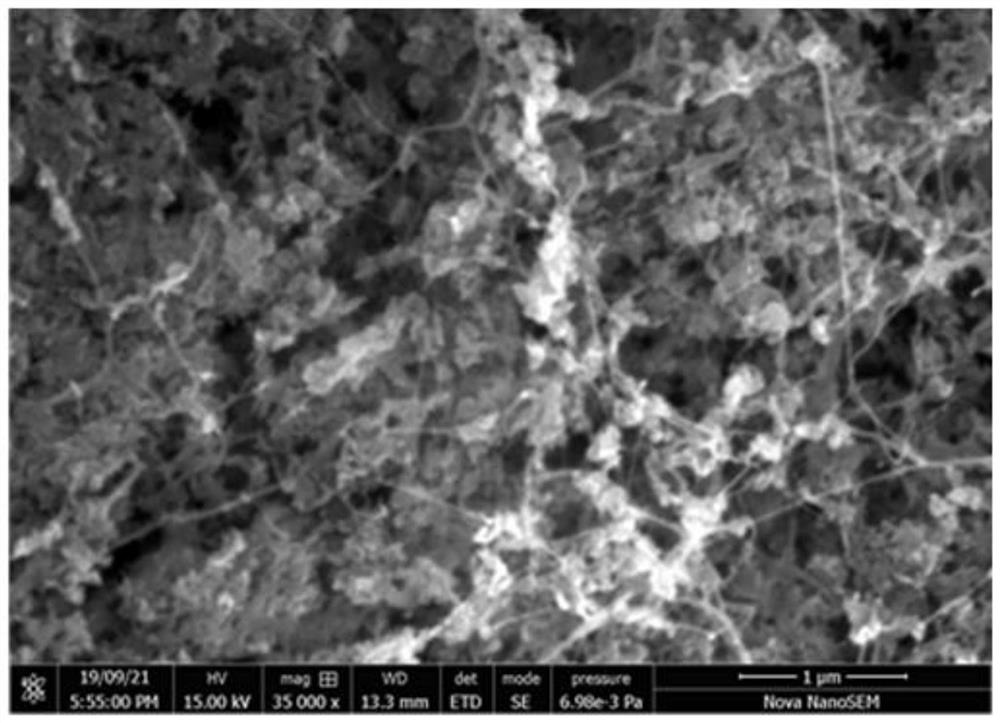

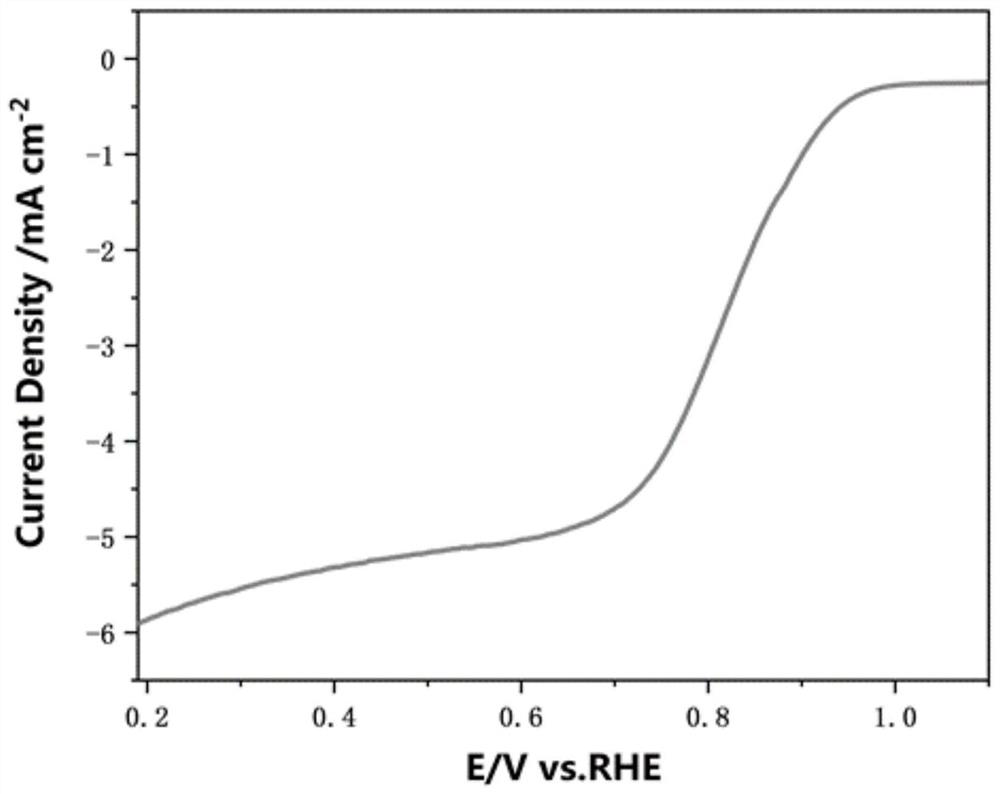

Image

Examples

Embodiment 1

[0034] (1) Cut the bacterial cellulose membrane into square pieces of 4 square centimeters, then put it into a beaker and boil for 20 minutes. Cool to room temperature before use.

[0035] (2) Prepare 50mL of hydrothermal solution, in which the volume ratio of water, ethanol, ferric iron ethanol solution and dimethyl ammonium acetate mixture is 1.5:1:1:35. Ferric iron ethanol solution is ferric nitrate nonahydrate ethanol solution, the concentration is 0.15mol / L, the dimethylammonium acetate mixed solution is the mixed solution of dimethylammonium acetate and polyacrylonitrile, and the concentration of dimethylammonium acetate is 0.3mol / L L.

[0036] (3) Put 4 square tablets of bacterial cellulose into 50mL of hydrothermal solution, then place them in an autoclave, and heat them at 110°C for 22h. After the completion of the hydrothermal process, the autoclave was naturally cooled to room temperature, and the iron-MOF-loaded bacterial cellulose was taken out and washed with m...

Embodiment 2

[0040] (1) Cut the bacterial cellulose membrane into square pieces of 4 square centimeters, then put it into a beaker and boil for 20 minutes. Cool to room temperature before use.

[0041] (2) Prepare 50mL of hydrothermal solution, in which the volume ratio of water, ethanol, ferric ethanol solution and dimethylammonium acetate mixture is 1:1:1:35. Ferric iron ethanol solution is ferric nitrate nonahydrate ethanol solution, the concentration is 0.2mol / L, the dimethylammonium acetate mixed solution is the mixed solution of dimethylammonium acetate and polyacrylonitrile, and the concentration of dimethylammonium acetate is 0.4mol / L L.

[0042] (3) Put 4 square tablets of bacterial cellulose into 50mL of hydrothermal solution, then put them in an autoclave, and heat them at 120°C for 20h. After the completion of the hydrothermal process, the autoclave was naturally cooled to room temperature, and the iron-MOF-loaded bacterial cellulose was taken out and washed with methanol.

...

Embodiment 3

[0045] (1) Cut the bacterial cellulose membrane into square pieces of 4 square centimeters, then put it into a beaker and boil for 20 minutes. Cool to room temperature before use.

[0046] (2) Prepare 50mL of hydrothermal solution, in which the volume ratio of water, ethanol, ferric ethanol solution and dimethyl ammonium acetate mixture is 2:1:1:40. Ferric iron ethanol solution is ferric nitrate nonahydrate ethanol solution, concentration is 0.1mol / L, dimethyl ammonium acetate mixed solution is dimethyl ammonium acetate and polyacrylonitrile mixed solution, dimethyl ammonium acetate concentration is 0.2mol / L L.

[0047] (3) Put 4 bacterial cellulose squares into 50mL of hydrothermal solution, then place them in an autoclave, and heat them at 100°C for 23h. After the completion of the hydrothermal process, the autoclave was naturally cooled to room temperature, and the iron-MOF-loaded bacterial cellulose was taken out and washed with methanol.

[0048] (4) Freeze-dry the iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com