Negative electrode material with porous carbon coating layer, preparation method of negative electrode material and lithium ion battery

A negative electrode material, porous carbon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electrolyte compatibility and exfoliation of graphite layers, and achieve improved electrochemical performance, improved dispersibility, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

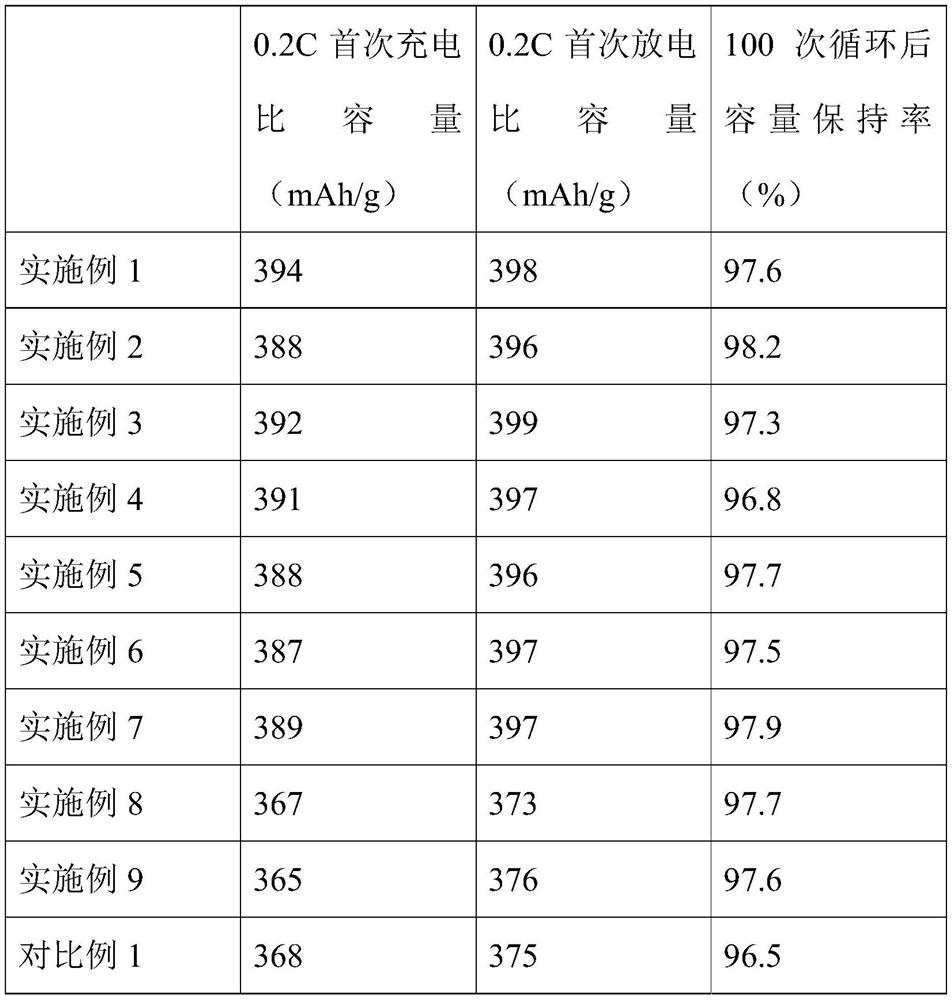

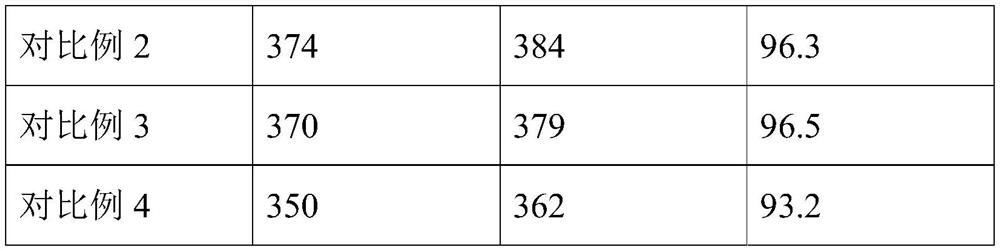

Examples

Embodiment 1

[0052] A preparation method of a negative electrode material with a porous carbon coating layer, comprising the following steps:

[0053] (1) phenolic resin is dispersed in the mixed solvent of cyclohexanol and dehydrated alcohol to obtain phenolic resin solution for subsequent use (for subsequent step (2) and step (3)), the quality of the cyclohexanol and dehydrated alcohol The ratio is 0.8:1, and the mass ratio of the phenolic resin and the organic solvent is 1:100;

[0054] (2) adopt the mixing of formaldehyde and ammonia water to carry out reductive emulsification to phenolic resin solution, the NH of described phenolic resin, formaldehyde and ammonia water 3 The mass ratio of phenolic resin is 1:0.5:0.2, then freeze-drying at -60°C, heating to 700°C for pre-carbonization at 1°C / min, and cooling to room temperature to obtain modified phenolic resin;

[0055] (3) mixing the modified phenolic resin and potassium hydroxide in a mass ratio of 3:1, and performing an activation...

Embodiment 2

[0060] A preparation method of a negative electrode material with a porous carbon coating layer, comprising the following steps:

[0061] (1) phenolic resin is dispersed in the mixed solvent of cyclohexanol and dehydrated alcohol to obtain phenolic resin solution for subsequent use (for subsequent step (2) and step (3)), the quality of the cyclohexanol and dehydrated alcohol The ratio is 0.7:1, and the mass ratio of the phenolic resin and the organic solvent is 2.5:100;

[0062] (2) adopt the mixing of formaldehyde and ammonia water to carry out reductive emulsification to phenolic resin solution, the NH of described phenolic resin, formaldehyde and ammonia water 3 The mass ratio of phenolic resin is 1:0.4:0.3, then freeze-dried at -75°C, heated to 750°C for pre-carbonization at 3°C / min, and cooled to room temperature to obtain modified phenolic resin;

[0063] (3) mixing the modified phenolic resin and potassium hydroxide according to a mass ratio of 4:1, and performing an a...

Embodiment 3

[0068] A preparation method of a negative electrode material with a porous carbon coating layer, comprising the following steps:

[0069] (1) phenolic resin is dispersed in the mixed solvent of cyclohexanol and dehydrated alcohol to obtain phenolic resin solution for subsequent use (for subsequent step (2) and step (3)), the quality of the cyclohexanol and dehydrated alcohol The ratio is 0.6:1, and the mass ratio of the phenolic resin and the organic solvent is 2:100;

[0070] (2) adopt the mixing of formaldehyde and ammonia water to carry out reductive emulsification to phenolic resin solution, the NH of described phenolic resin, formaldehyde and ammonia water 3 The mass ratio of phenolic resin is 1:0.5:0.25, and then freeze-dried at -70°C, heated to 750°C for pre-carbonization at 2°C / min, and cooled to room temperature to obtain modified phenolic resin;

[0071] (3) mixing the modified phenolic resin and potassium hydroxide in a mass ratio of 2.5:1, and performing an activa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com