C4 alkylation catalyst and method for preparing high-octane gasoline through C4 alkylation

A high-octane gasoline and carbon tetraalkyl technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of increasing catalyst costs and improve activity and anti-carbon deposition performance , Strong anti-carbon deposition ability, high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

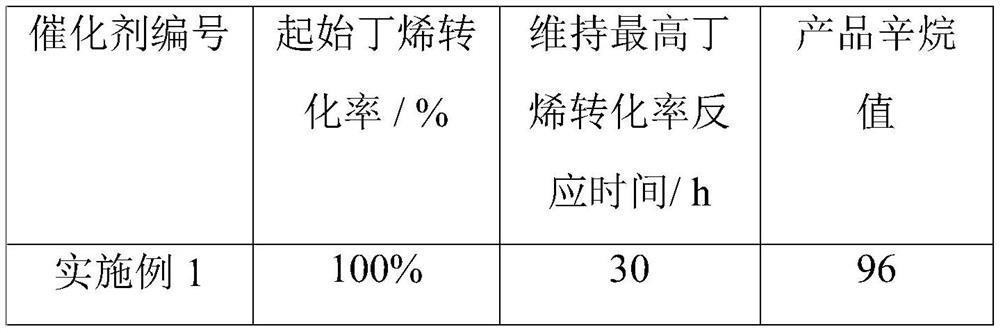

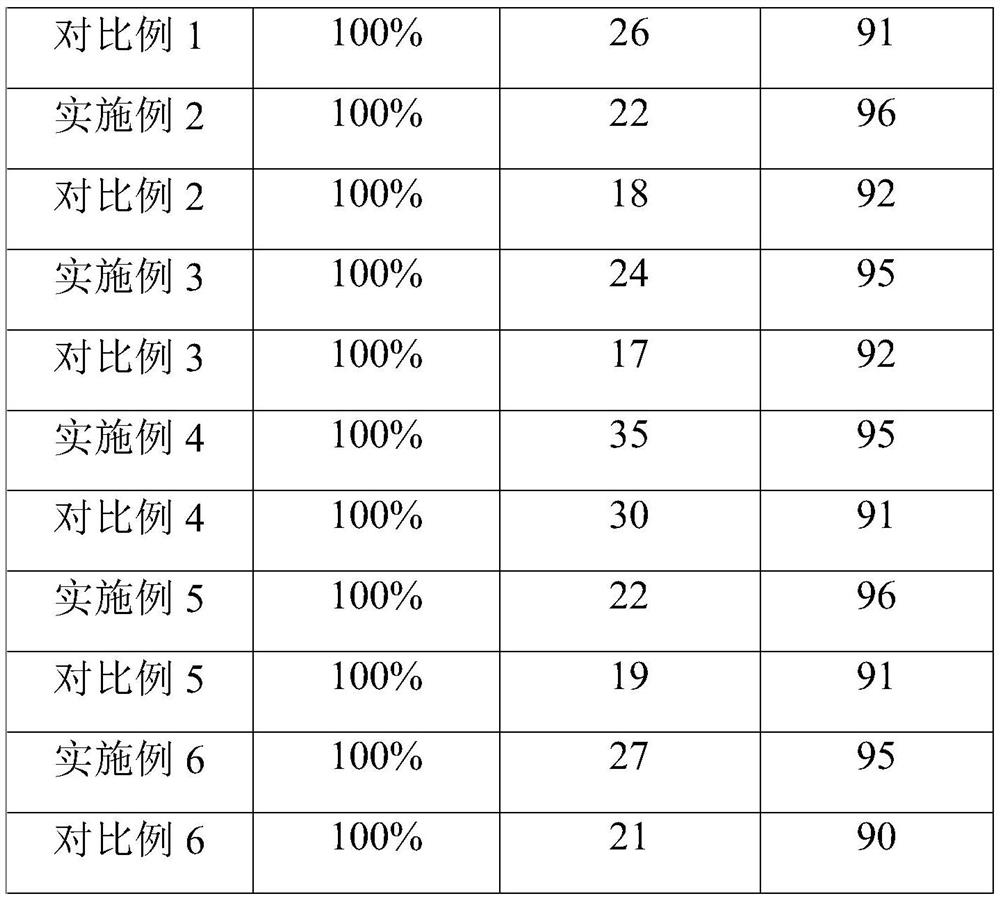

Examples

Embodiment 1

[0028] (1) Preparation of directing agent

[0029] Add 2.3g of sodium hydroxide, 1.4g of pseudo-boehmite and 11.9g of deionized water into the beaker, stir to dissolve completely, add 12.6g of sodium silicate solution, stir vigorously, seal and age for 24 hours to obtain a directing agent solution ;

[0030] (2) Preparation of Mo modified Y molecular sieve

[0031] Add 6.3g of molybdenum cyclohexanoate into 50.0g of cyclohexane, and stir evenly after dissolving to form an organic solution containing molybdenum;

[0032] 63.7g sodium hydroxide, 82.9g sodium aluminate and 890g silica sol (35wt% SiO 2 content) into 2000g deionized water in turn, and stirred at room temperature until a uniform sol solution was formed;

[0033] Add the prepared directing agent solution to the sol solution, stir evenly, add the molybdenum-containing organic solution, and continue stirring until a uniform sol solution is formed;

[0034] Transfer the above sol solution into a hydrothermal crystal...

Embodiment 3

[0068] This example provides a preparation method for in-situ synthesis of Mo-modified Y molecular sieve and its application example in C4 alkylation reaction:

[0069] Add 2.3g of sodium hydroxide, 1.35g of pseudo-boehmite and 11.9g of deionized water into the beaker, stir to dissolve completely, add 12.6g of sodium silicate solution, stir vigorously, seal and age for 24 hours to obtain a directing agent solution ;

[0070] Add 6.6g of molybdenum cyclohexanoate into 68.5g of cyclohexane, stir evenly to form molybdenum-containing organic solution after dissolving completely;

[0071] With 76.9g sodium hydroxide, 105.6g pseudo-boehmite and 900g water glass solution (30wt%SiO 2 content) into 2100g deionized water in turn, and stirred at room temperature until a uniform sol solution was formed;

[0072] Add the prepared directing agent to the sol solution, stir evenly, then add the molybdenum-containing organic solution, and continue stirring until a uniform sol solution is for...

Embodiment 4

[0087] This example provides a preparation method for in-situ synthesis of Mo-modified Y molecular sieve and its application example in C4 alkylation reaction:

[0088] Add 2.3g of sodium hydroxide, 1.35g of pseudo-boehmite and 11.9g of deionized water into the beaker, stir to dissolve completely, add 12.6g of sodium silicate solution, stir vigorously, seal and age for 24 hours to obtain a directing agent solution ;

[0089] Add 9.0g of molybdenum octadecyl salicylate into 80.0g of cyclohexane, and stir evenly after dissolving to form an organic solution containing molybdenum;

[0090] 51.3g sodium hydroxide, 89.8g sodium aluminate, and 700g silica sol (35wt% SiO 2 Content) was added to 2500g deionized water in turn, and stirred at room temperature until a uniform sol solution was formed;

[0091] Add the prepared directing agent to the sol solution, stir evenly, then add the molybdenum-containing organic solution, and continue stirring until a uniform sol solution is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com