Preparation method of MnO-SiO2 insulation coated metal soft magnetic powder core

A technology of insulation coating and metal soft magnetism, which is applied in the manufacture of inductors/transformers/magnets, preventing/reducing unwanted electric/magnetic effects, parts of transformers/inductors, etc., and can solve the problem of oxide coating methods Uneven coating, easy aging of the coating layer, easy falling off of the coating layer, etc., to achieve the effects of not easy to decompose and fall off, avoid aging problems, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

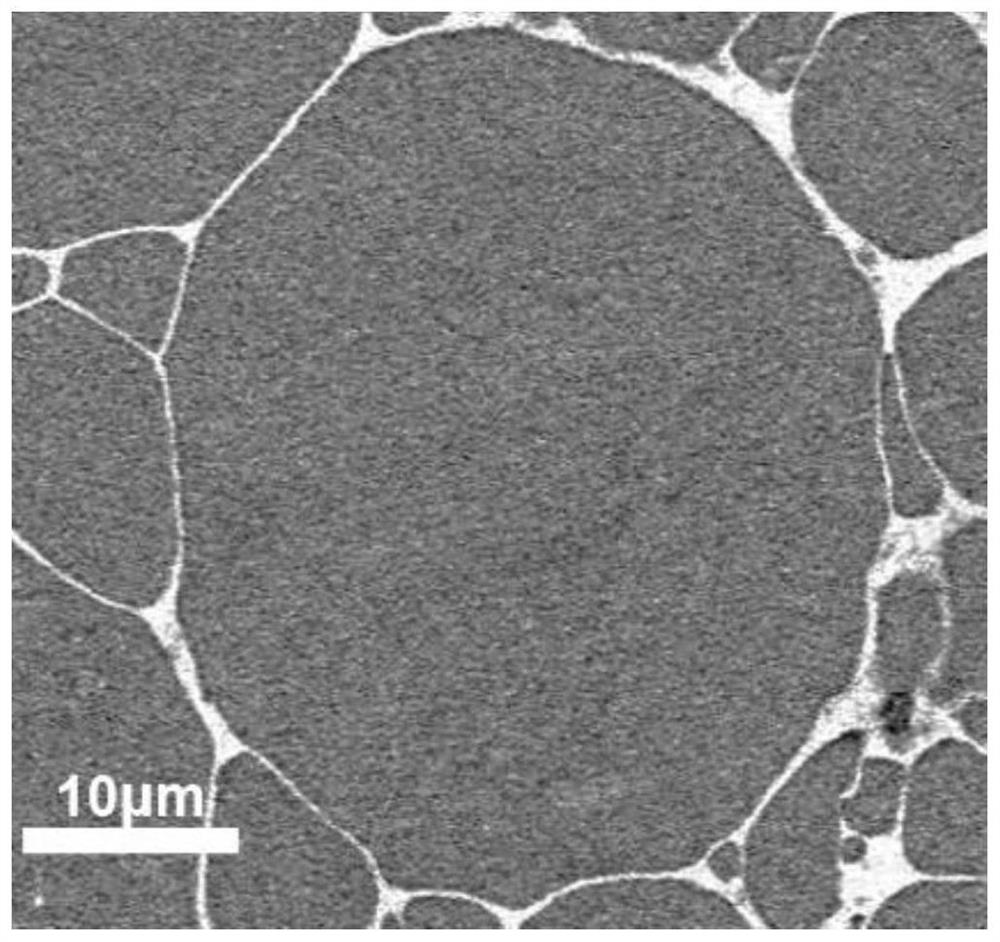

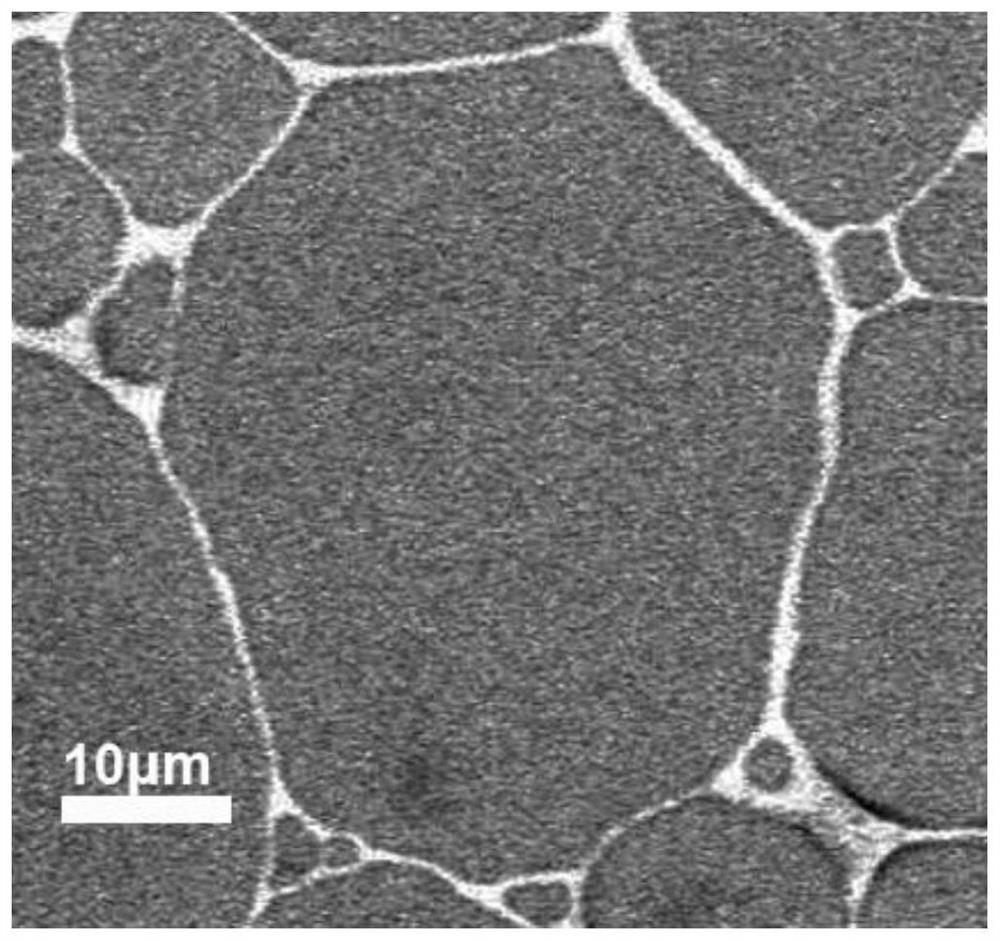

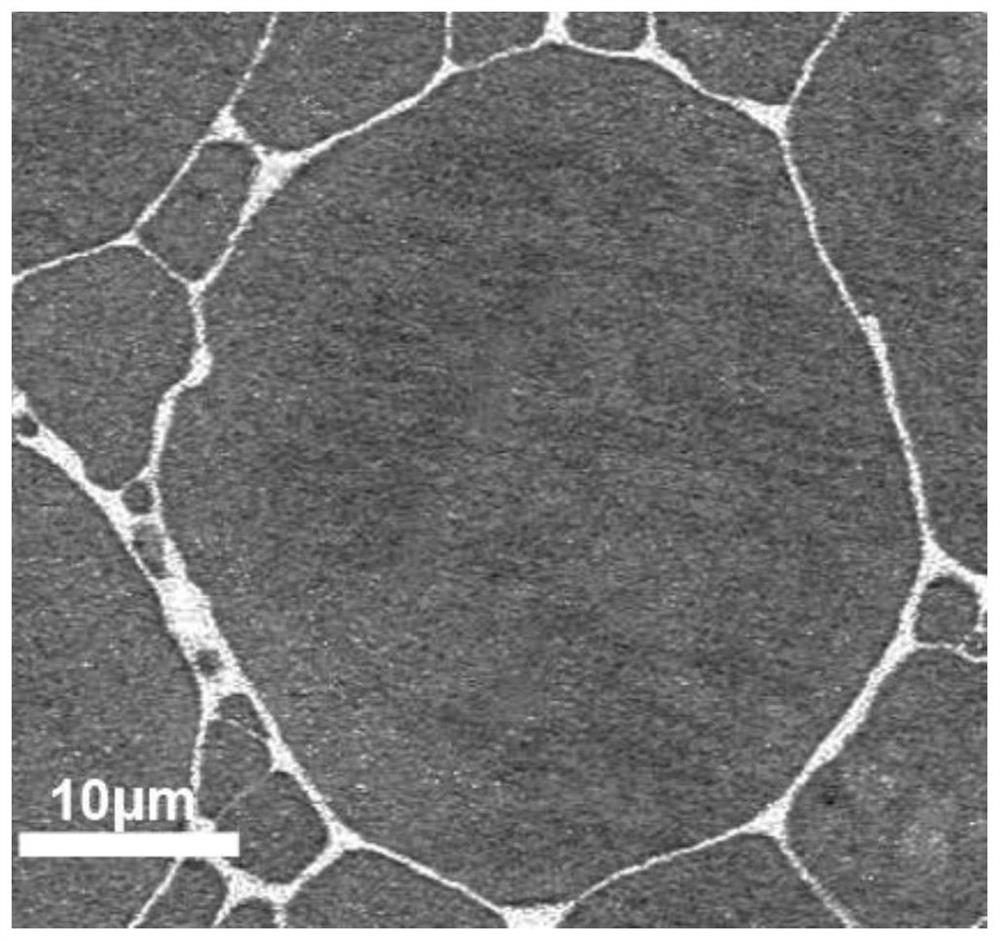

Image

Examples

Embodiment 1

[0039] (1) 12gMnO 2 Add 0.12gKH550 and 6gH 2 O mixed solution, and mechanically stirred for 1h to obtain the modified MnO 2 mixed solution;

[0040] (2) Add 300 g of sendust magnetic powder and 6 g of ethanol to the mixed solution in step (1), stir mechanically for 1 h, and then dry at 120° C. for 1 h to obtain MnO 2 Insulation-coated sendust powder;

[0041] (3) MnO obtained in step (2) 2 The sendust powder after the insulation coating is passed through a 200-mesh sieve, sieved and granulated, then weighed 200g of the granulated powder, and added 0.6g of resin binder and 0.8g of zinc stearate to mix evenly, and then used The hydraulic press performs two-way floating pressing under the pressure of 1860MPa, and the density is 5.73g / cm 3 green body;

[0042] (4) Annealing treatment: place the green body obtained in step (3) in an annealing furnace, and pass nitrogen gas into it, exhaust the air in the furnace, and under the protection of nitrogen gas, heat up at a rate of ...

Embodiment 2

[0049] (1) 24gMnO 2 Add 0.24gKH550 and 12gH 2 O mixed solution, and mechanically stirred for 1h to obtain the modified MnO 2 mixed solution;

[0050] (2) Add 300 g of sendust magnetic powder and 12 g of ethanol to the mixed solution in step (1), stir mechanically for 1 h, and then dry at 120° C. for 1 h to obtain MnO 2 Insulation-coated sendust powder;

[0051] (3) MnO obtained in step (2) 2 The sendust powder after the insulation coating is passed through a 200-mesh sieve, sieved and granulated, then weighed 200g of the granulated powder, and added 0.6g of resin binder and 0.8g of zinc stearate to mix evenly, and then used The hydraulic press performs two-way floating pressing under the pressure of 1860MPa, and the density is 5.58g / cm 3 green body;

[0052] (4) Annealing treatment: place the green body obtained in step (3) in an annealing furnace, and pass nitrogen gas into it, exhaust the air in the furnace, and under the protection of nitrogen gas, heat up at a rate o...

Embodiment 3

[0059] (1) 30gMnO 2 Add 0.3gKH550 and 15gH 2 O mixed solution, and mechanically stirred for 1h to obtain the modified MnO 2 mixed solution;

[0060] (2) Add 300 g of ferrosilicon magnetic powder and 15 g of ethanol to the mixed solution in step (1), stir mechanically for 1 h, and then dry at 120 ° C for 1 h to obtain MnO 2 Iron-silicon powder after insulation coating;

[0061] (3) MnO obtained in step (2) 2 The sendust powder after the insulation coating is passed through a 200-mesh sieve, sieved and granulated, then weighed 200g of the granulated powder, and added 0.6g of resin binder and 0.8g of zinc stearate to mix evenly, and then used The hydraulic press performs two-way floating pressing under the pressure of 1860MPa, and the density is 6.08g / cm 3 green body;

[0062] (4) Annealing treatment: place the green body obtained in step (3) in an annealing furnace, and pass nitrogen gas into it, exhaust the air in the furnace, and under the protection of nitrogen gas, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com