Preparation method of m-trifluoromethyl acetophenone oxime

A technology of trifluoromethyl acetophenone oxime and trifluoromethyl aniline is applied in the field of preparation of m-trifluoromethyl acetophenone oxime, and can solve the problem of high salt content in coupling liquid waste water, high three waste treatment costs, and high industrialization costs problems, to achieve the effect of reducing operating costs and equipment investment, reducing the cost of three wastes treatment, and high content and yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

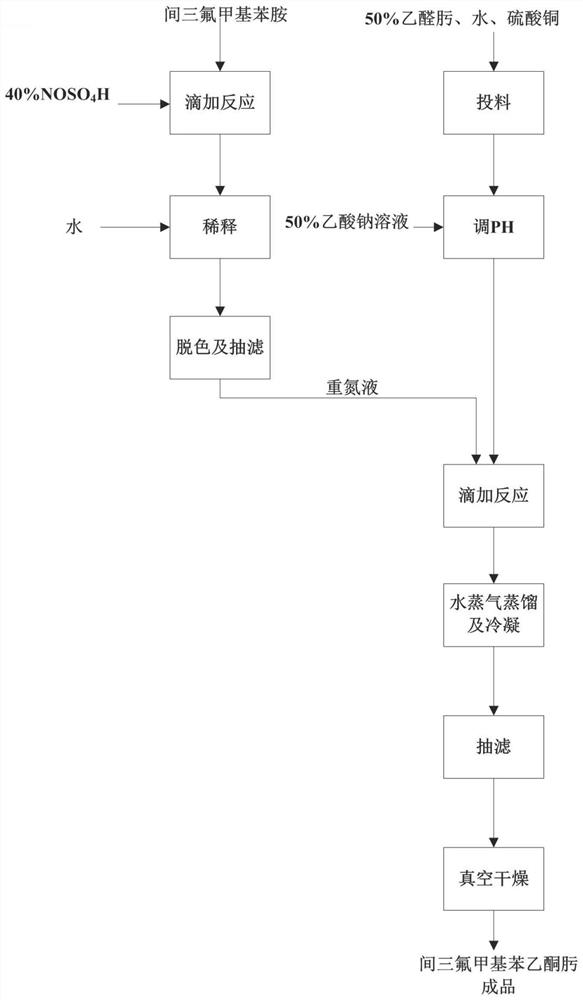

Method used

Image

Examples

Embodiment 1

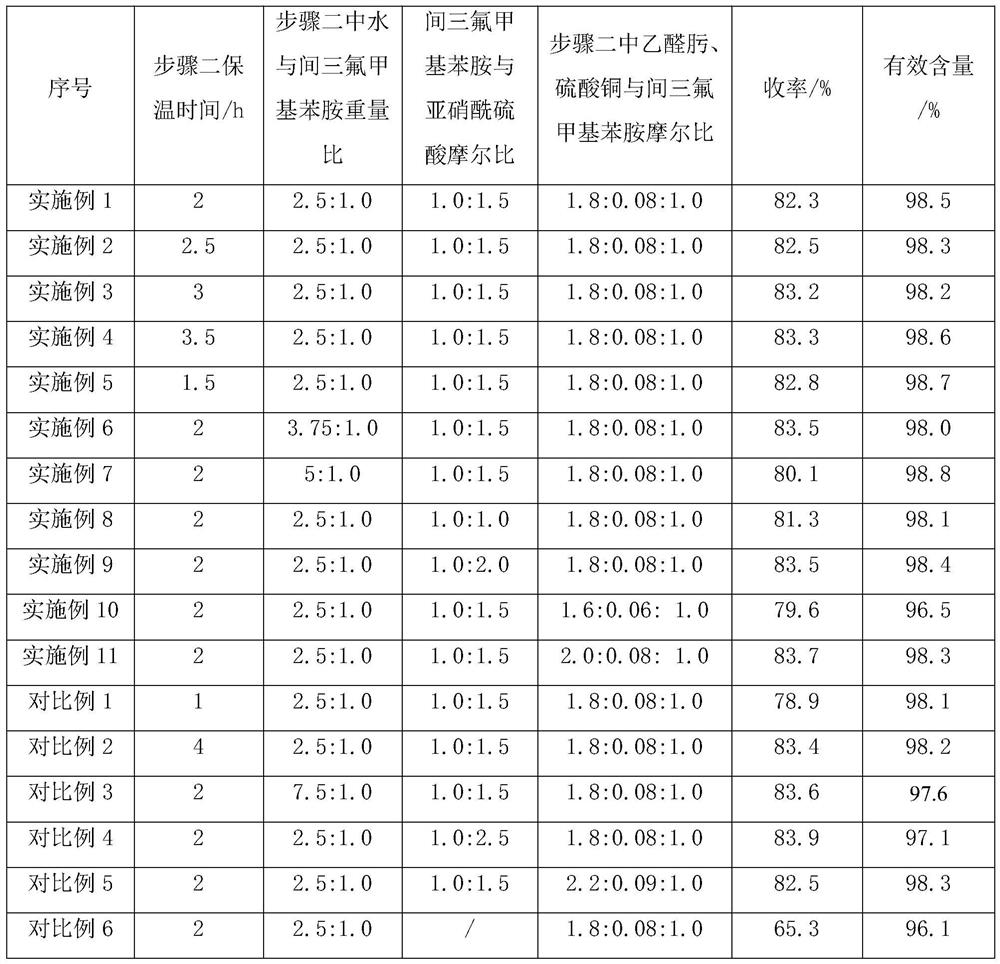

[0029] Example 1: In step 2, dinitrogen solution was added dropwise, and the temperature was continued for 2 hours to obtain a coupling solution.

[0030] A kind of preparation method of m-trifluoromethyl acetophenone oxime, this preparation method comprises the steps:

[0031] Step 1: Under nitrogen protection, add 40% nitrosyl sulfuric acid (NOSO 4 H) 47.63g, start stirring and cool down to 5°C, slowly add m-trifluoromethylaniline 16.11g dropwise, continue to keep warm for 1h after the dropwise addition, then slowly add 161.10g water to dilute the diazonium solution, dropwise at 0°C, After the dropwise addition was completed, after decolorization and adsorption by activated carbon, a yellow clear diazonium salt solution was obtained by suction filtration, which was kept cold for later use.

[0032] Step 2: Under the protection of nitrogen, put 0.18mol of 50% acetaldehyde oxime solution, 40.28g of water and 0.008mol of copper sulfate catalyst in a 1000mL four-neck flask succ...

Embodiment 2

[0034] Embodiment 2: In step 2, the diazo solution is added dropwise, and the insulation is continued for 2.5h to obtain the coupling solution.

[0035] A kind of preparation method of m-trifluoromethyl acetophenone oxime, this preparation method comprises the steps:

[0036] Step 1: Under nitrogen protection, add 40% nitrosyl sulfuric acid (NOSO 4 H) 47.63g, start stirring and cool down to 7°C, slowly add m-trifluoromethylaniline 16.11g dropwise, continue to keep warm for 1.5h after the dropwise addition, then slowly add 161.10g water to dilute the diazonium solution, dropwise at 2°C After the dropwise addition was completed, after being decolorized and adsorbed by activated carbon, a yellow clear diazonium salt solution was obtained by suction filtration, which was kept cold for later use.

[0037] Step 2: Under the protection of nitrogen, put 0.18mol of 50% acetaldehyde oxime solution, 40.28g of water and 0.008mol of copper sulfate catalyst in a 1000mL four-neck flask succ...

Embodiment 3

[0039] Embodiment 3: In step 2, heavy nitrogen liquid is added dropwise, and the insulation is continued for 3h to obtain coupling liquid.

[0040] A kind of preparation method of m-trifluoromethyl acetophenone oxime, this preparation method comprises the steps:

[0041] Step 1: Under nitrogen protection, add 40% nitrosyl sulfuric acid (NOSO 4 H) 47.63g, start stirring and cool down to 8°C, slowly add m-trifluoromethylaniline 16.11g dropwise, continue to keep warm for 1.5h after the dropwise addition, then slowly add 161.10g water to dilute the diazonium solution, dropwise at 3°C After the dropwise addition was completed, after being decolorized and adsorbed by activated carbon, a yellow clear diazonium salt solution was obtained by suction filtration, which was kept cold for later use.

[0042] Step 2: Under the protection of nitrogen, put 0.18mol of 50% acetaldehyde oxime solution, 40.28g of water and 0.008mol of copper sulfate catalyst in a 1000mL four-neck flask successiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com